Bamboo shoot dietary fiber degradable chewing gum and preparation method thereof

A bamboo shoot dietary fiber and chewing gum technology, which is applied in chewing gum, cocoa, food science, etc., can solve the problems of environmental pollution and difficult removal, and achieve the effect of smooth and beautiful surface, less pollution, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Bamboo shoots dietary fiber degradable chewing gum, by weight percentage, consists of the following components:

[0035] Gum base raw material 62%, bamboo shoot dietary fiber superfine powder 10%, emulsifier 2.5%, moisture retention agent 5%, antioxidant 4%, thickener 2.2%, stabilizer 1.8%, sweetener 10%, sour agent 0.5% % and potato flour 2.0%.

[0036] Its preparation method comprises the following steps:

[0037] Get the gum base raw material, bamboo shoots dietary fiber superfine powder, emulsifier, water retaining agent, antioxidant, thickener, stabilizer, sweetener and sour agent powder extrusion mix uniformly respectively according to the proportioning, make chewing gum gum base, then It is extruded with a template to make sugar embryos, dried and aged, calendered and cut into sugar cubes, then coated with a layer of potato flour on the surface of the sugar cubes, and packaged to obtain bamboo shoot dietary fiber degradable chewing gum.

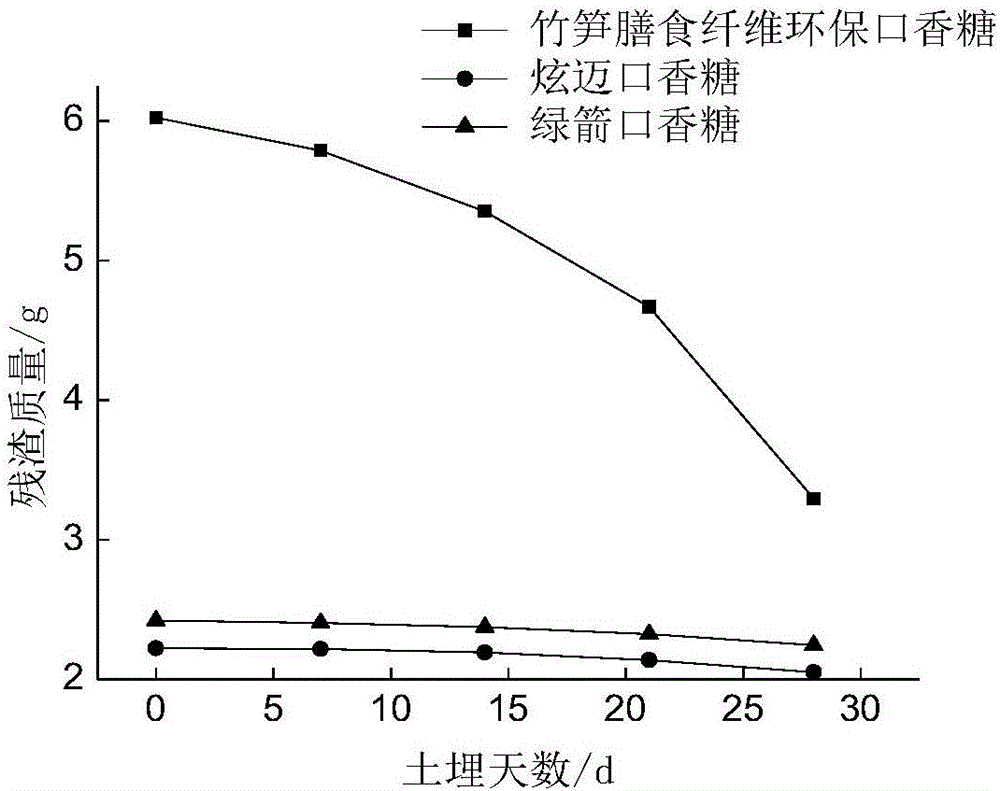

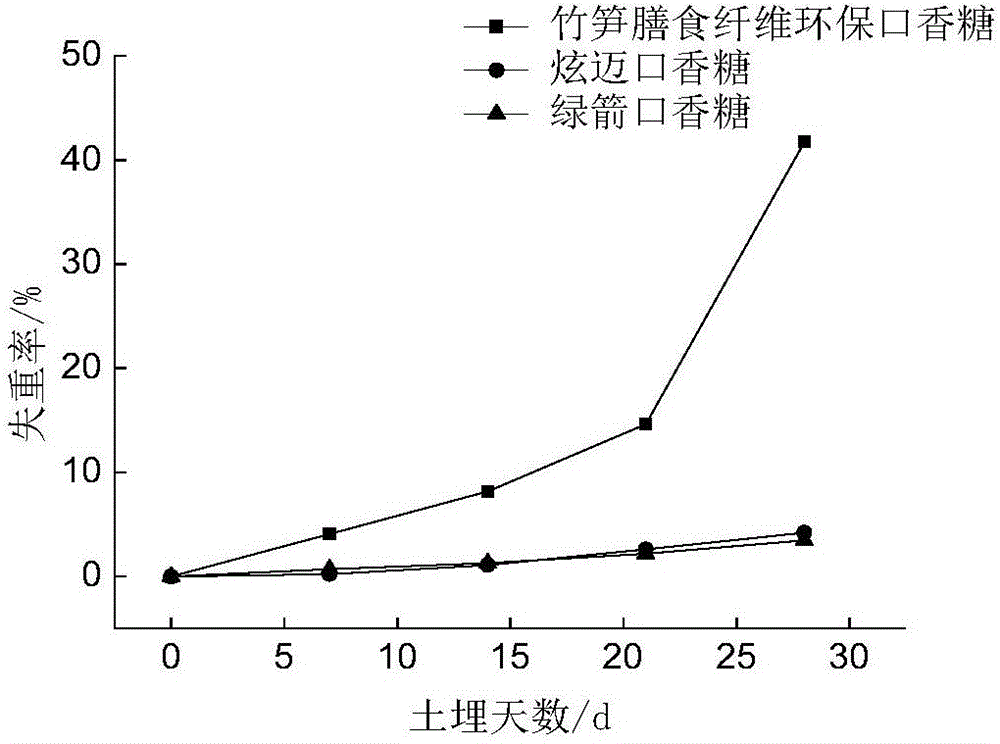

[0038] After measureme...

Embodiment 2

[0040] Bamboo shoot dietary fiber degradable chewing gum is composed of the following components by weight percentage: 72.5% of gum base material, 5% of bamboo shoot dietary fiber superfine powder, 2% of emulsifier, 4.5% of moisture retaining agent, 3% of antioxidant, and thickener 2% sweetener, 1.5% stabilizer, 8% sweetener, 0.5% sour agent and 1% potato flour.

[0041] The preparation method comprises the following steps: respectively taking gum base raw materials, superfine powder of bamboo shoot dietary fiber, emulsifier, moisture retaining agent, antioxidant, thickener, stabilizer, sweetener and sour agent powder, extruding and mixing uniformly according to the proportioning ratio, The chewing gum base is made, then extruded with a template to make sugar embryos, dried and aged, calendered and cut into sugar cubes, then coated with a layer of potato flour on the surface of the sugar cubes, and packaged to obtain bamboo shoot dietary fiber degradable chewing gum.

[0042] ...

Embodiment 3

[0044] The degradable chewing gum with bamboo shoot dietary fiber is composed of the following components by weight percentage: 65% of gum base material, 5% of superfine powder of bamboo shoot dietary fiber, 2% of emulsifier, 4.7% of moisture retaining agent, 3.8% of antioxidant, thickener 2% sweetener, 2% stabilizer, 10% sweetener, 1% sour agent and 4.5% potato flour.

[0045] The preparation method comprises the following steps: respectively taking gum base raw materials, superfine powder of bamboo shoot dietary fiber, emulsifier, moisture retaining agent, antioxidant, thickener, stabilizer, sweetener and sour agent powder, extruding and mixing uniformly according to the proportioning ratio, The chewing gum base is made, then extruded with a template to make sugar embryos, dried and aged, calendered and cut into sugar cubes, then coated with a layer of potato flour on the surface of the sugar cubes, and packaged to obtain bamboo shoot dietary fiber degradable chewing gum.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com