Micromixer for fluid materials

A fluid material, micro-mixing technology, applied in mixers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficulty in manufacturing large-scale micro-mixing equipment and high equipment production costs, saving raw materials and reducing equipment bulk density. , the effect of high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

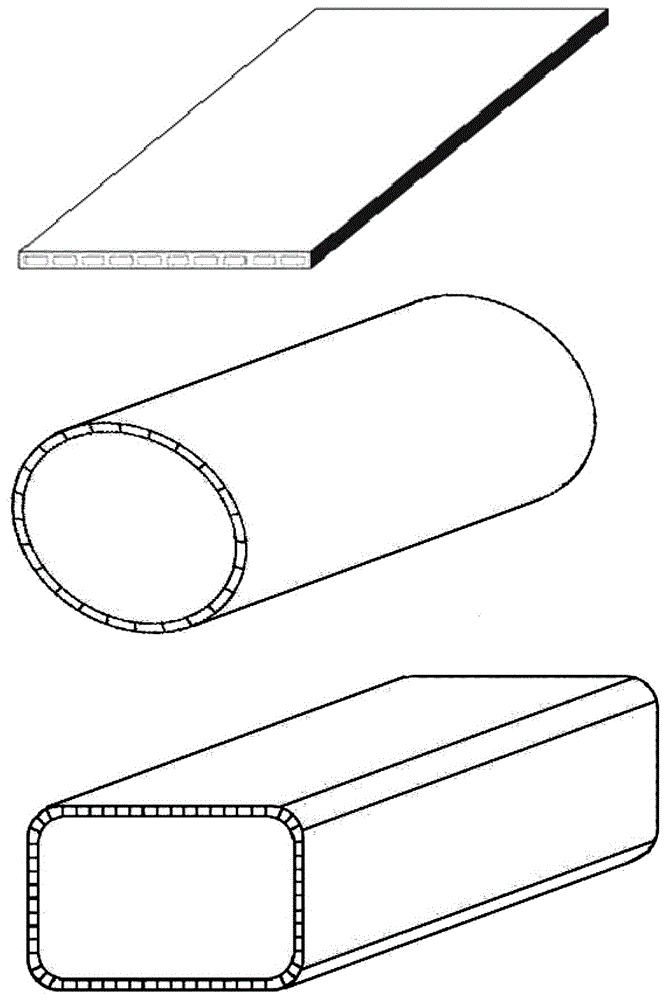

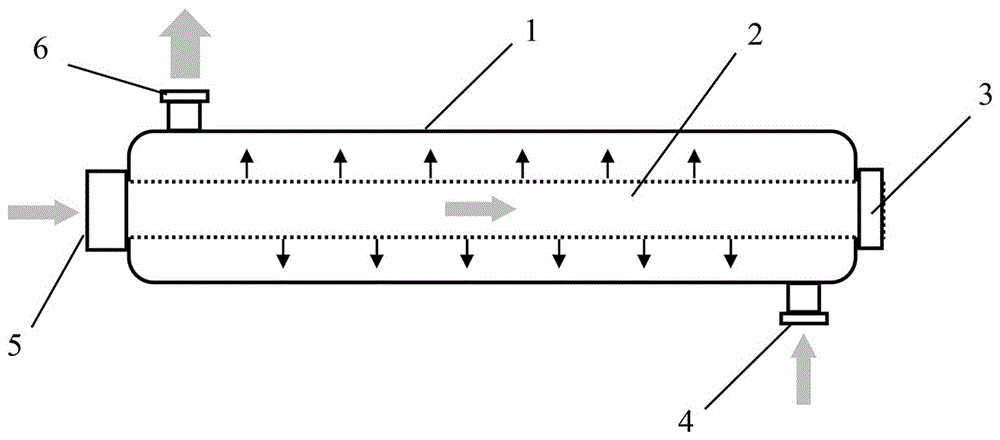

[0035] A micro-hybrid device based on a planar multi-channel ceramic element with a structure such as figure 2 shown.

[0036] Wherein, the flat multi-channel ceramic element is a porous alumina material. The manufacturing steps of the ceramic element are as follows:

[0037] 1. Mix 4 kg of alumina powder with a median particle size of 20 μm and 0.2 kg of firing aids evenly;

[0038] 2. Add 300 g of methyl cellulose, 150 g of glycerin, 15 g of oleic acid, 150 g of vacuum mineral oil and 900 g of water, and through the steps of mixing, mud refining, aging, etc., to obtain plastic mud;

[0039] 3. Use an extruder to extrude the mud into a flat multi-channel green body;

[0040] 4. The green body is dried by microwave radiation;

[0041]5. The dried green body is heated up to 400°C at a speed of 2°C / min and kept for 1 hour, and then heated to 1400°C at a speed of 2°C / min for 2 hours, and then cooled with the furnace.

[0042] After the fired ceramic product is cut, it is ob...

specific Embodiment 2

[0047] A micro-mixing device based on a flat multi-channel ceramic element, the basic structure of which is similar to the specific example 1, except that the micro-mixing device includes 10 ceramic elements 2 arranged in parallel. By increasing the number of ceramic elements 2, the material handling capacity of the micro-mixing device can be conveniently increased.

specific Embodiment 3

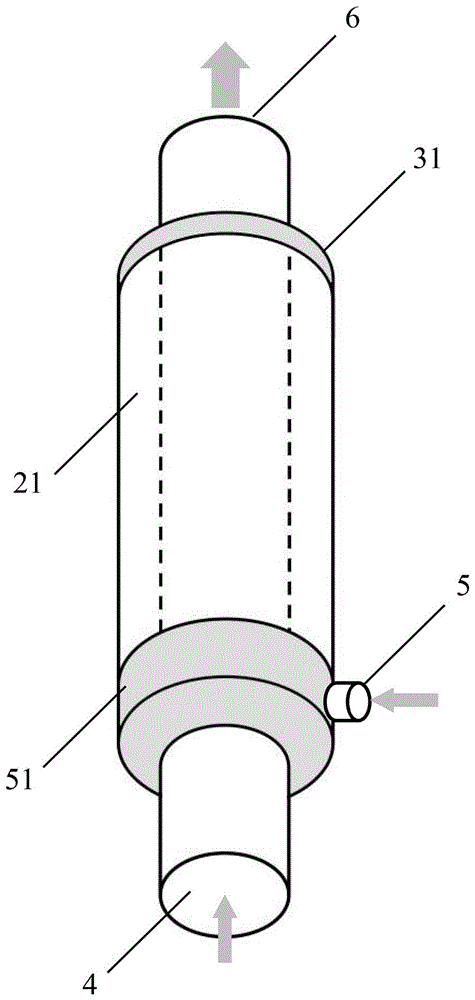

[0049] A micro-hybrid device based on a cylindrical multi-channel ceramic element, the basic structure of which is image 3 shown.

[0050] Wherein, the cylindrical multi-channel ceramic element is a porous silicon carbide material. The manufacturing steps of the ceramic element are as follows:

[0051] 1. Mix 4.5 kg of black silicon carbide powder with a median particle size of 12 μm, 0.3 kg of kaolin with a median particle size of 0.5 μm, and 0.2 kg of alumina powder with a median particle size of 0.5 μm;

[0052] 2. Add 300 g of hydroxypropyl methylcellulose, 120 g of glycerin, 15 g of oleic acid, 120 g of vacuum mineral oil and 850 g of water, and through the steps of mixing, mud refining, aging, etc., to obtain plastic mud;

[0053] 3. Use an extruder to extrude the mud into a circular multi-channel green body;

[0054] 4. After drying the green body at room temperature for 24 hours, put it in an oven at 80°C for 8 hours;

[0055] 5. The dried green body is heated up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com