Food waste treatment method, control system and foot waste treatment device

A technology for food waste treatment and food waste, applied in grain treatment and other directions, can solve the problems of poor grinding effect, breaking into small particles, forming eddy currents, etc., to achieve better crushing effect, avoid water, electricity, and crushing. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

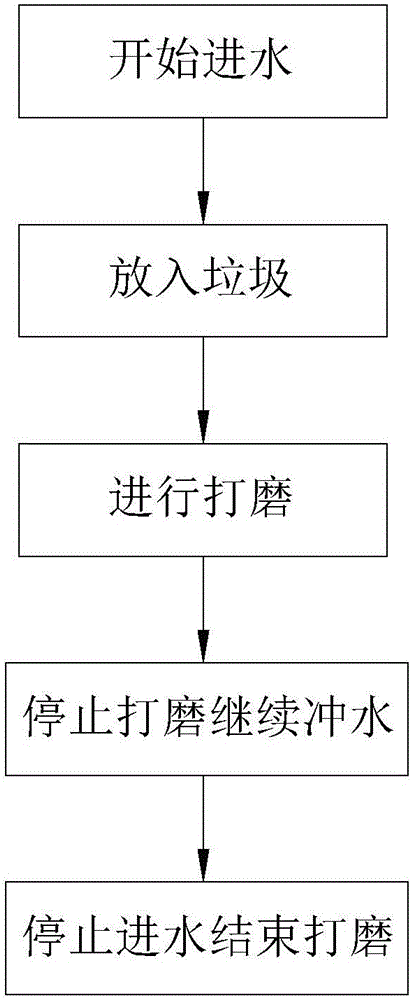

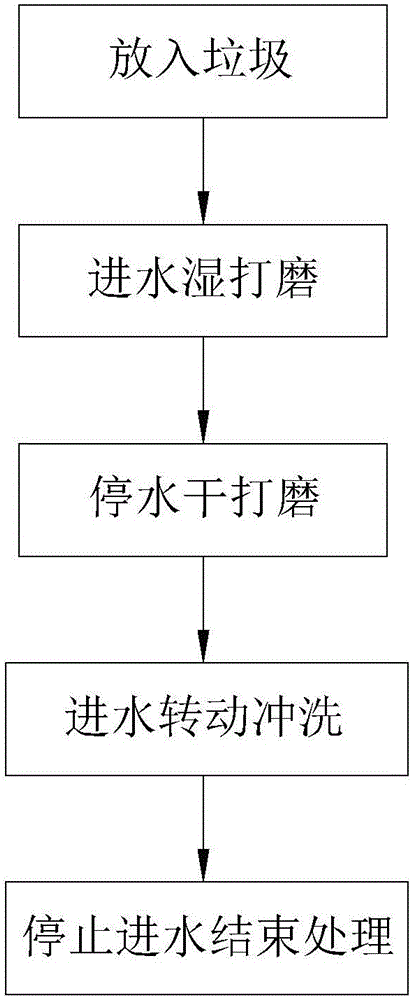

[0055] A kind of food waste treatment method, with reference to figure 2 , including the following processing procedures: Step 1, put in garbage; Step 2, enter water and perform wet grinding; Step 3, stop water intake for dry grinding; Step 4, perform cleaning; Step 5, stop water intake to end the treatment.

[0056] Among them, the garbage can be put in all at one time in the process of step 1, or the garbage can be put in multiple times in steps 1 and 2. After the garbage is put in, step 2 is advanced for T1 time, and then For wet grinding, in this example, T1 is 3 seconds. The reason why the water is advanced for 3 seconds is that if the water and grinding are carried out at the same time, it is easy to cause the machine to jam. After the food waste is soaked in water, it is easier to grind. In other embodiments, the advanced water can also be used for a shorter or longer time.

[0057] In the process of step two wet grinding, the food waste is continuously broken, the sm...

Embodiment 2

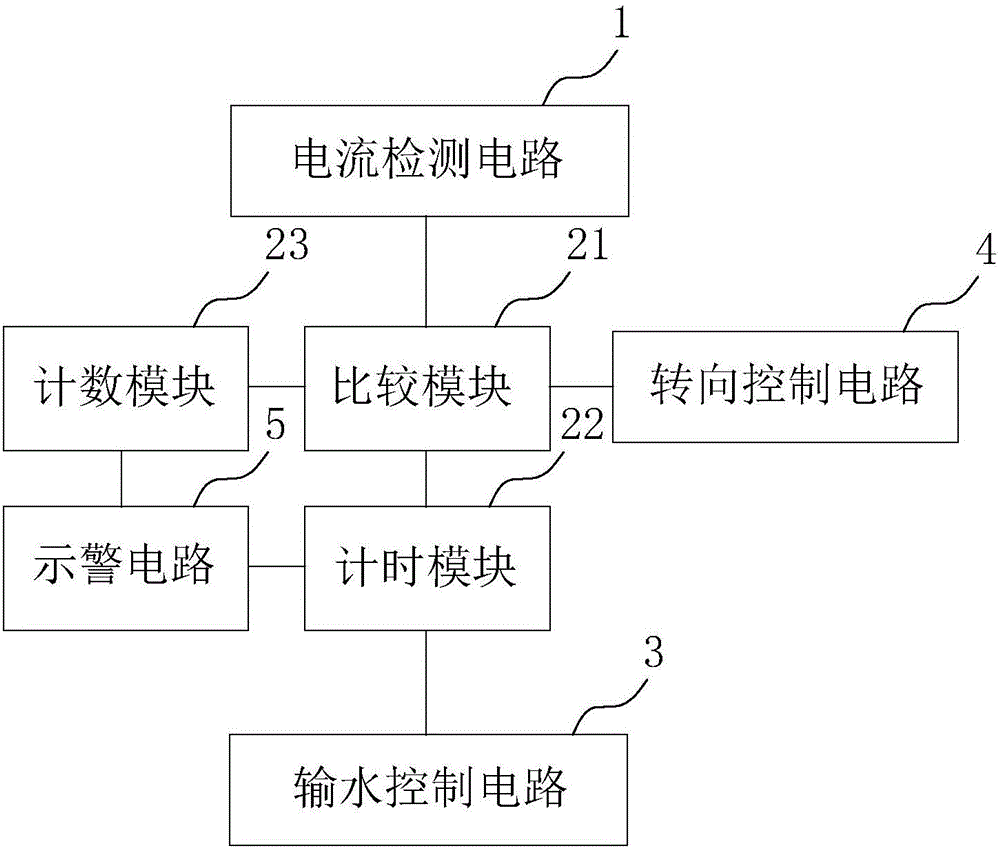

[0063] A food waste treatment control system, referring to image 3 , including a power control circuit, a pneumatic switch control circuit 6, a wireless signal receiving circuit 7, an alarm circuit 5, a comparison module 21, a timing module 22, a water delivery control circuit 3 and a steering control circuit 4.

[0064] refer to Figure 4 , the power supply control circuit transforms the mains power by transforming, rectifying and stabilizing it to output +24V, +12V, +5V power supply and provide the running power of the motor. In addition, the power supply control circuit adopts electromagnetic compatibility design (EMC), electromagnetic Compatible design (EMC) can suppress electromagnetic interference, improve the anti-interference ability of the system, and is conducive to the stable operation of the entire control system. Since the specific electromagnetic compatibility design (EMC) is a prior art, it will not be repeated in the present invention.

[0065] When performin...

Embodiment 3

[0076] A food waste disposer, including the food waste treatment control system in Embodiment 2, refer to Figure 8 to Figure 10 , also includes a housing 10, a grinding device 11 located in the housing 10 for breaking food, and a water delivery device 12 for delivering water to the processor.

[0077] refer to Figure 8 as well as Figure 9 , the housing 10 adopts a split design, which is divided into upper, middle and lower parts, and the two adjacent parts are fixed by bolts, so that it can be easily disassembled. At the entrance, there is a splash guard 14 for preventing the food from being ground and broken, and the water delivery device 12 is arranged on one side of the upper part of the housing 10. In this embodiment, the water delivery device 12 is adopted as The solenoid valve electrically connected to the water delivery control circuit 3 can deliver water to the processor at a constant flow under the control of the water delivery control circuit 3, and a certain wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com