Manufacturing method for environment-friendly type high-density wood and bamboo fiber board

A kind of bamboo fiber and environment-friendly technology, applied in the direction of wood processing equipment, pretreatment of molding materials, manufacturing tools, etc., can solve the problems of waste water and gas discharge energy consumption, high energy consumption, poor waterproof performance, etc., to achieve no waste water discharge, Good flame retardant performance and good styling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

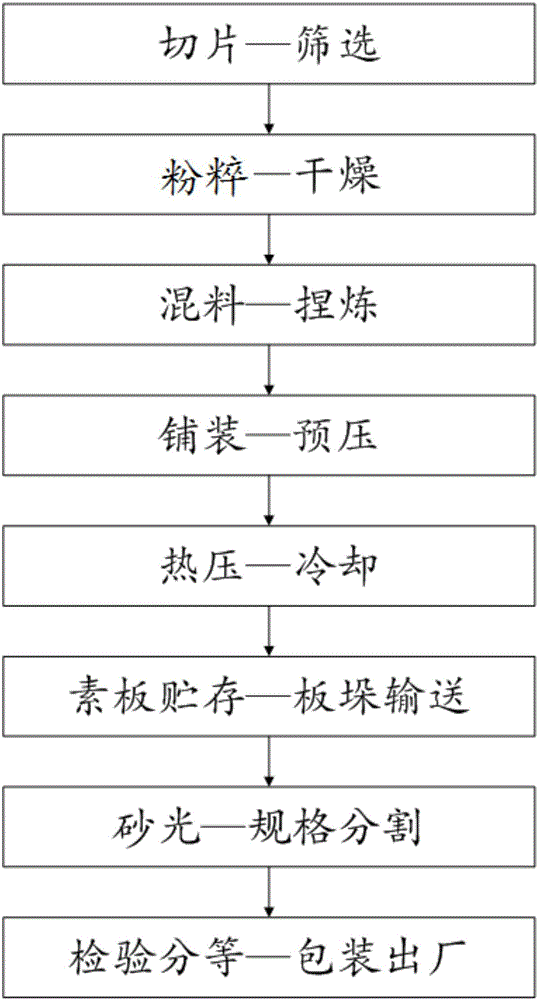

[0028] like figure 1 Shown, a kind of environment-friendly type high-density wood bamboo fiber board manufacture method,

[0029] The environment-friendly high-density wood and bamboo fiber plate disclosed by the invention is composed of 50-60% of wood fiber; 20-30% of bamboo fiber; 20-30% of pvc; 8-15% of medical stone, and 1-3% of environmentally friendly flame retardant constitute.

[0030] The environment-friendly high-density wood-bamboo fiber plate disclosed by the invention is further optimized, and is composed of 50% of wood fiber, 20% of bamboo fiber, 20% of pvc, 8% of medical stone and 2% of environmentally friendly flame retardant.

[0031] The manufacturing method of the environment-friendly high-density wood and bamboo fiber board disclosed by the invention comprises the following steps:

[0032] An environment-friendly high-density wood and bamboo fiber board manufacturing method, comprising the following steps:

[0033]Step 1. Slicing-screening: (1) All the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com