Method for treating sewage containing radioactive substances

A technology for radioactive substances and sewage, applied in the direction of radioactive pollutants, filtration treatment, sludge treatment, etc., can solve problems such as poor effect, and achieve the effect of large specific surface area, good adsorption and filtration performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

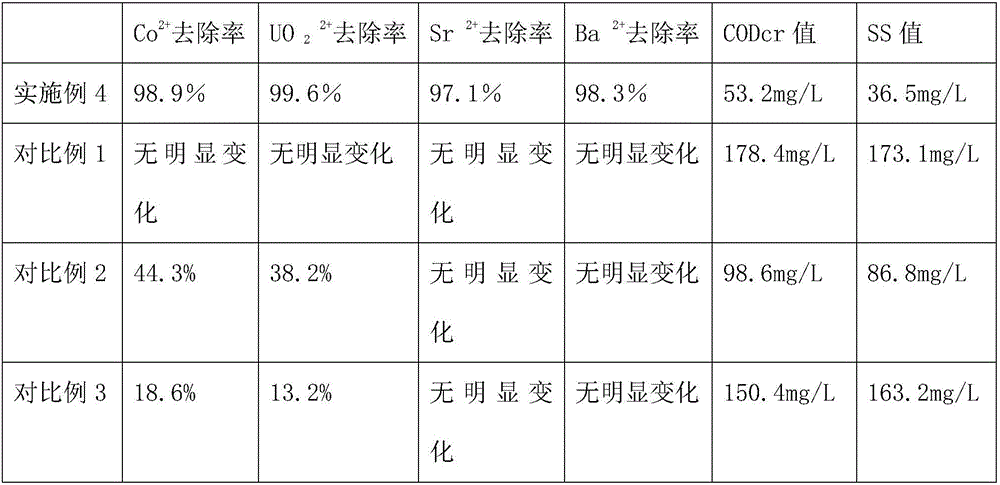

Examples

Embodiment 1

[0020] Example 1: Get 52 parts of vermiculite powder, 27 parts of active calcium silicate, 5 parts of pyroxene, 9 parts of basalt fiber, 2.3 parts of calcium sulfate, 0.4 part of carbon nanotube, 7 parts of nano titanium dioxide, 1.3 parts of potassium tartrate and silica sol 11 parts; crush basalt fiber through a 180-mesh sieve, add nano-titanium dioxide and silica sol, stir and grind for 1 hour, and dry at 180°C to obtain modified nano-titanium dioxide; mix modified nano-titanium dioxide and vermiculite powder at 250°C for 1 hour Add water and stir potassium tartrate until completely dissolved, stir the previous material for 0.6h, raise the temperature to 100°C and continue stirring for 1h, then add active calcium silicate and other remaining ingredients to disperse and grind for 3h, dry and discharge.

Embodiment 2

[0021] Embodiment 2: get 42 parts of vermiculite powder, 25 parts of active calcium silicate, 7 parts of pyroxene, 11 parts of basalt fiber, 4.1 parts of calcium sulfate, 0.2 part of carbon nanotube, 9 parts of nano titanium dioxide, 2.5 parts of potassium tartrate and silica sol 8 parts; crush the basalt fiber through a 180-mesh sieve, add nano-titanium dioxide and silica sol, stir and grind for 1.2 hours, and dry at 160°C to obtain modified nano-titanium dioxide; mix and stir the modified nano-titanium dioxide and vermiculite powder at 220°C for 1.3 h: Stir the potassium tartrate with water until it is completely dissolved, stir the previous material for 0.5h, raise the temperature to 90°C and continue stirring for 0.8h, then add active calcium silicate and other remaining ingredients to disperse and grind for 2h, dry and discharge.

Embodiment 3

[0022] Embodiment 3: get 54 parts of vermiculite powder, 37 parts of active calcium silicate, 6 parts of pyroxene, 10 parts of basalt fiber, 3 parts of calcium sulfate, 0.3 part of carbon nanotube, 10 parts of nano titanium dioxide, 2 parts of potassium tartrate and silica sol 10 parts; crush the basalt fiber through a 150-mesh sieve, add nano-titanium dioxide and silica sol, stir and grind for 2 hours, and dry at 150°C to obtain modified nano-titanium dioxide; mix and stir the modified nano-titanium dioxide and vermiculite powder at 200°C for 1.5 h: Stir the potassium tartrate with water until it is completely dissolved, stir the previous material for 0.8h, raise the temperature to 110°C and continue stirring for 0.5h, then add active calcium silicate and other remaining ingredients to disperse and grind for 2.5h, dry and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com