Antiferroelectric high-energy-density ceramic material and preparation method thereof

A ceramic material, antiferroelectric technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of many types of elements, insufficient breakdown field strength, obvious nonlinear characteristics, etc., and achieve high electric field induced polarization. The effect of high strength, high pressure resistance and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the preparation method of the present invention, MgWO is first synthesized 4 powder, then synthesize PbHfO 3 -PbMg 0.5 W 0.5 o 3 The solid solution ceramic powder is sintered by a two-step method, and finally the antiferroelectric ceramic material is prepared, which specifically includes the following steps:

[0039] Step 1: Using PbO, HfO 2 , MgO and WO 3 Powder as raw material, according to PbO, HfO 2 , MgO and WO 3 The molar ratio of the powder is (1+a): (1-x): 0.5(1+b)x: 0.5x Take each raw material for later use, where a and b are compensation parameters, and a=0.01~0.05, b =0.01~0.05, x=0.01~0.25; 1~5mol% of MgO is in excess to compensate for the volatilization loss of MgO at high temperature, and the excess of PbO is 1~5mol% to compensate for the volatilization loss of PbO in the high temperature sintering process.

[0040] Step 2: Combine MgO and WO 3 Mix to form mixture A; take mixture A, zirconium balls and absolute ethanol respectively, mix them ac...

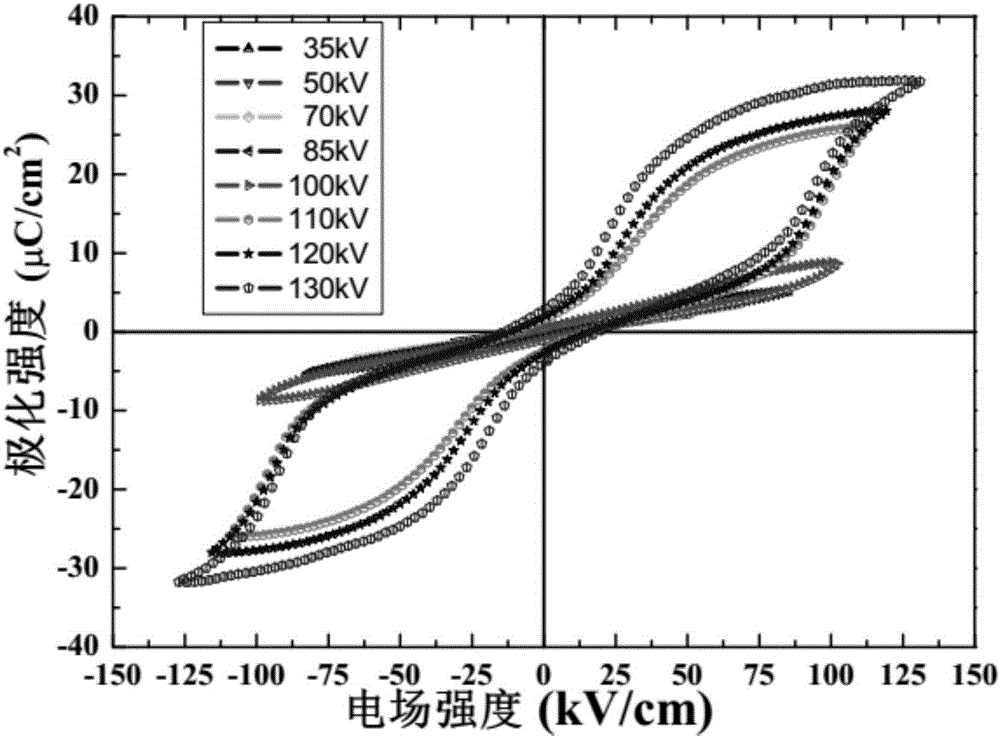

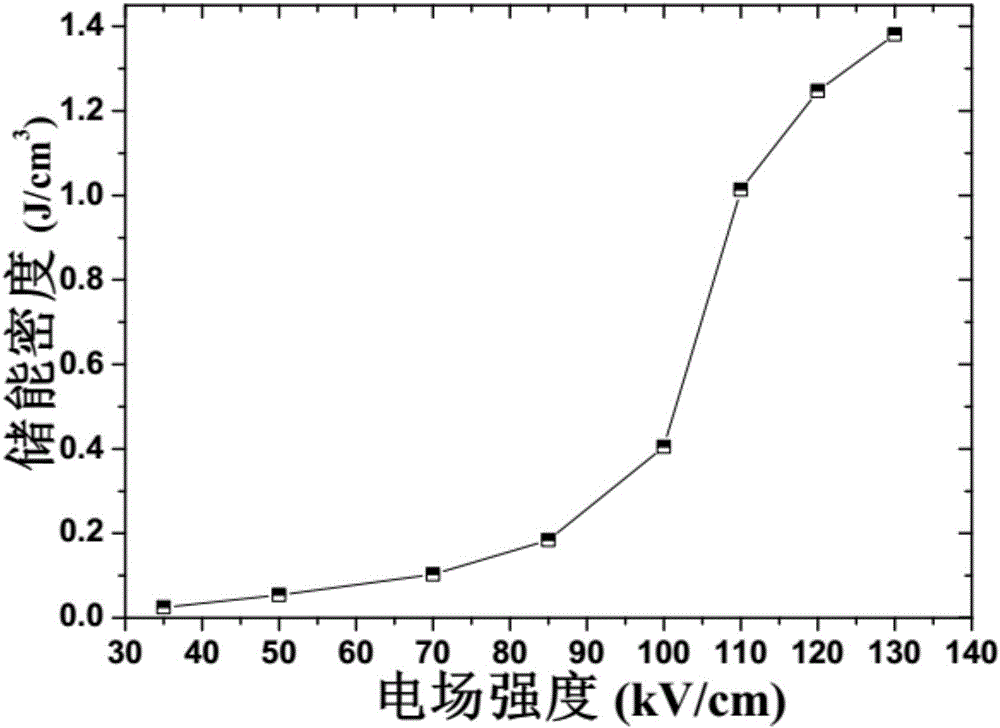

Embodiment 1

[0051] The preparation method of the antiferroelectric energy storage ceramic material of the embodiment of the present invention comprises the following steps:

[0052] (1) with PbO, HfO 2 , MgO and WO 3 Powder as raw material, according to PbO, HfO 2 , MgO and WO 3 The molar ratio of the powder is (1+a):(1-x):0.5(1+b)x:0.5x. Take each raw material for later use, where a=0.03, b=0.04, x=0.08;

[0053] First, MgWO was synthesized at 1000°C for 10 hours 4 powder; then, take HfO 2 , PbO and MgWO 4 Form the complete ingredients, use the wet chemical ball mill mixing method, ball mill for 12 hours, mix evenly, dry, briquetting, put in a muffle furnace at 850°C for 4 hours and pre-fire to form 0.92PbHfO 3 -0.08PbMg 0.5 W 0.5 o 3 The ceramic powder, as the main crystal phase powder, is reserved.

[0054] (2) smash and grind the ceramic powder obtained in step (1), sieve with a 120-mesh sieve to obtain a finer powder, then carry out secondary ball milling for 12 hours, obta...

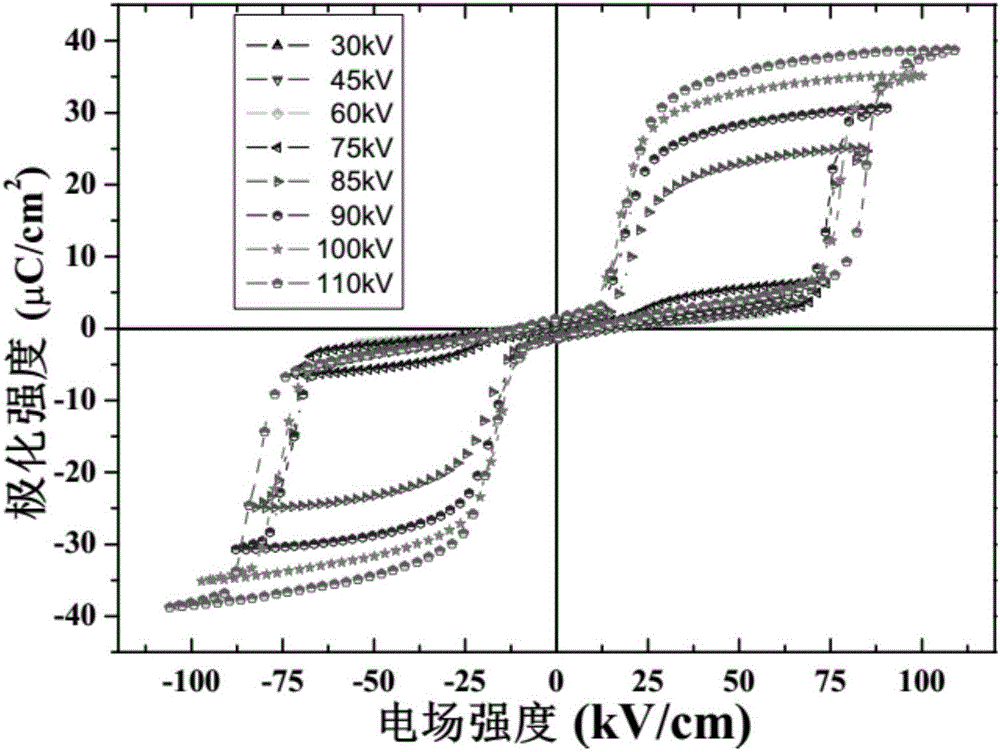

Embodiment 2

[0061] The preparation method of the antiferroelectric energy storage ceramic material of the embodiment of the present invention comprises the following steps:

[0062] (1) with PbO, HfO 2 , MgO and WO 3 Powder as raw material, according to PbO, HfO 2 , MgO and WO 3 The molar ratio of the powder is (1+a):(1-x):0.5(1+b)x:0.5x. Take each raw material for later use, where a=0.03, b=0.04, x=0.1;

[0063] First, MgWO was synthesized at 1000°C for 10 hours 4 powder; then, take HfO 2 , PbO and MgWO 4 Form the complete ingredients, use the wet chemical ball mill mixing method, ball mill for 12 hours, mix evenly, dry, briquetting, put in a muffle furnace at 850°C for 4 hours and pre-fire to form 0.9PbHfO 3 -0.1PbMg 0.5 W 0.5 o 3 Ceramic powder.

[0064] (2) smash and grind the ceramic powder obtained in step (1), sieve with a 120-mesh sieve to obtain a finer powder, then carry out secondary ball milling for 12 hours, obtain ceramic powder after drying, and then Add the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com