Diphenolic acid-based polyphosphate ester flame retardant containing DOPO structure and preparation method of flame retardant

A technology of bisphenolic acid-based polyphosphate and polyphosphate, applied in the field of polyphosphate and its preparation, can solve the problems of low flame retardant efficiency, toxic gas, poor thermal stability, etc. The effect of beneficial combustion performance and complex structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

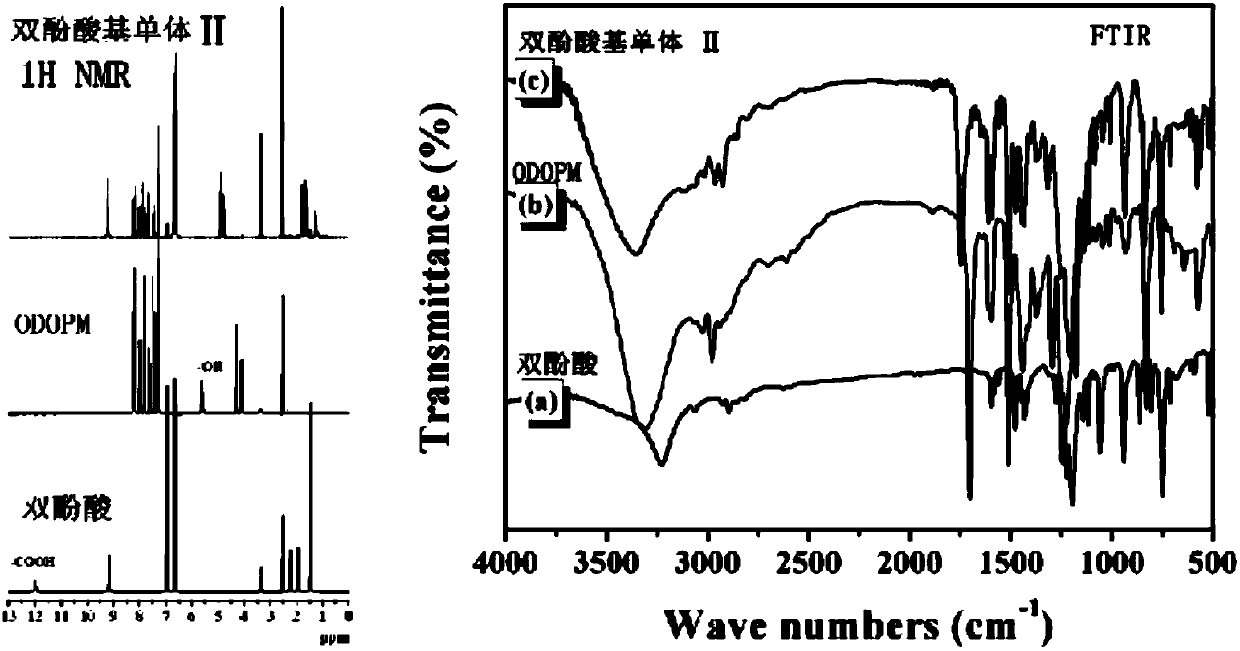

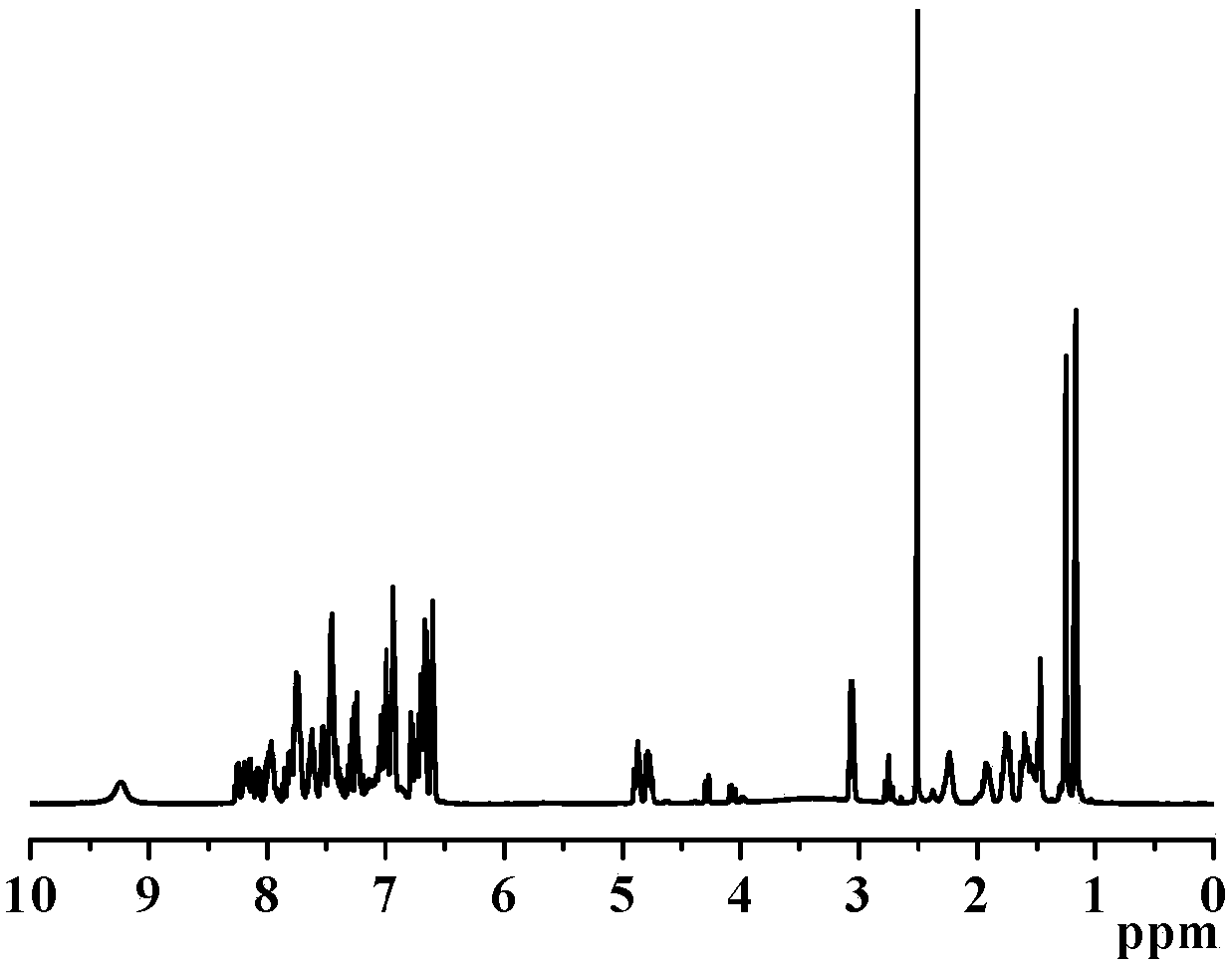

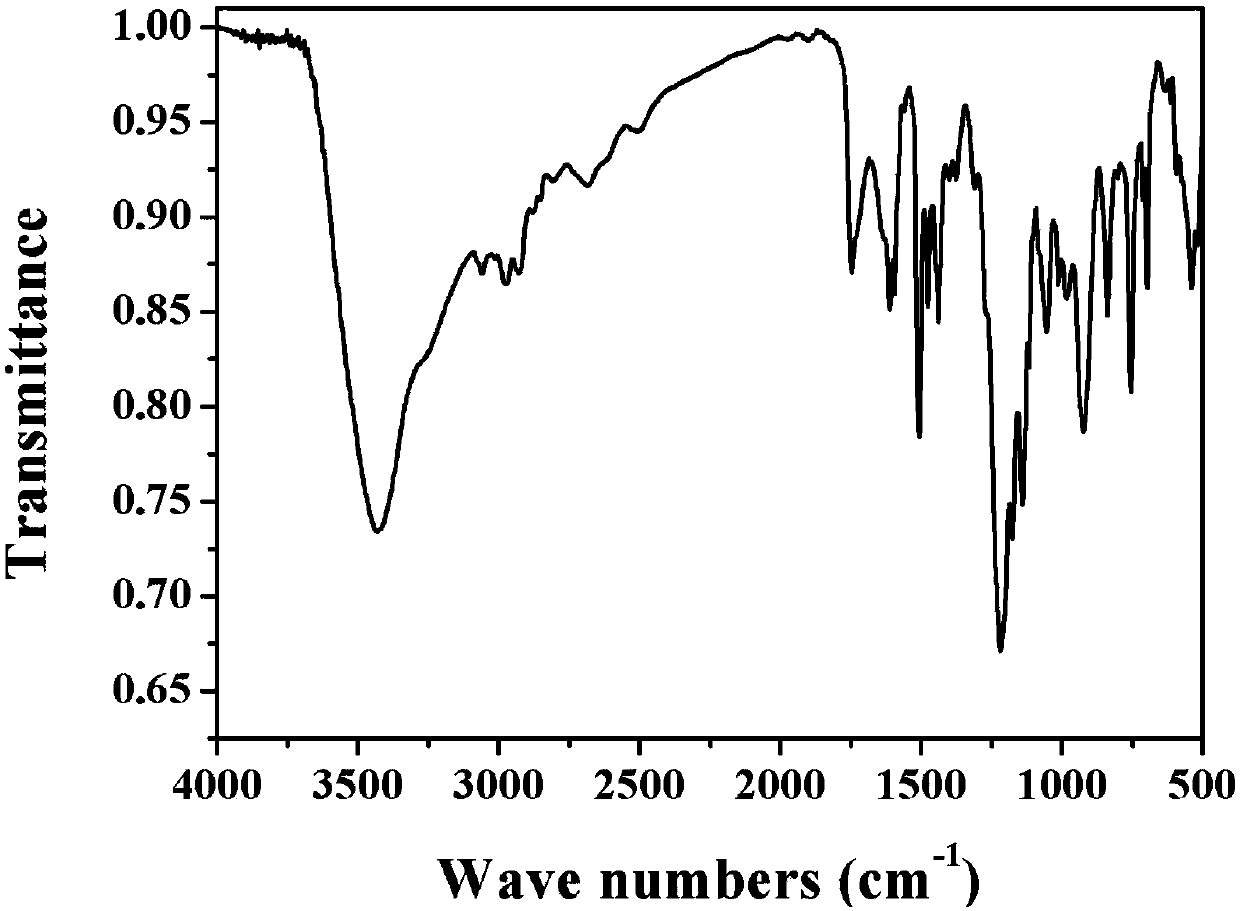

[0033] Add 28.6 g of bisphenolic acid (DPA; 4,4-di(4-hydroxyphenyl)pentanoic acid, CAS No. 126-00-1) and 9,10-dihydro-9-oxa- 10-phosphaphenanthrene-10-hydroxymethyl-10-oxide (ODOPM) 24.6g, concentrated sulfuric acid 5g, DMF 100mL. Protected by nitrogen gas, the reaction was refluxed for 40 hours under mechanical stirring. During this period, part of the azeotrope of DMF and water was distilled off five times, and then a corresponding volume of DMF was added to finally obtain a yellow transparent solution. The solvent was removed by rotary evaporation to obtain a crude product.

[0034] The crude product was added to deionized water at 100 °C to remove impurities. TLC was used to track until there was no bisphenolic acid in the upper layer of water, and then the product was filtered and vacuum-dried at 80° C. for 10 hours. Monomer (II) is obtained. (That 1 H NMR and FTIR spectra are attached figure 1 )

[0035] Synthesis of polyphosphate (Ⅲ): Add 25.7 g of monomer (II) a...

Embodiment 2

[0041] Add 28.6g of bisphenolic acid, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-hydroxymethyl-10-oxide (ODOPM) 22g, concentrated sulfuric acid 5.5g, DMF100mL, under nitrogen protection, reflux reaction for 35 hours under mechanical stirring. During this period, part of the azeotrope of DMF and water was distilled off seven times, and then a corresponding volume of DMF was added to obtain a yellow transparent solution. The solvent was removed by rotary evaporation to obtain a crude product.

[0042]The crude product was added into deionized water at 100°C for purification. TLC was used to track until there was no bisphenolic acid in the upper layer of water, and then the product was filtered and vacuum-dried at 80° C. for 10 hours. Monomer (II) is obtained.

[0043] Synthesis of polyphosphate (IV): Add 25.7 g of monomer (II) and 110 mL of ethyl acetate into a 250 mL three-necked flask, and flush with nitrogen gas for 10 minutes. Slowly raise the temperature to 40°C. Slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com