Preparation method of biodegradable supermolecule polylactic acid microspheres

A technology of polylactic acid microspheres and supramolecules, which can be applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., which can solve problems such as difficult removal and restrictions on the wide application of biodegradable particles. Achieve the effects of avoiding the use of emulsifiers, good biocompatibility, and high implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

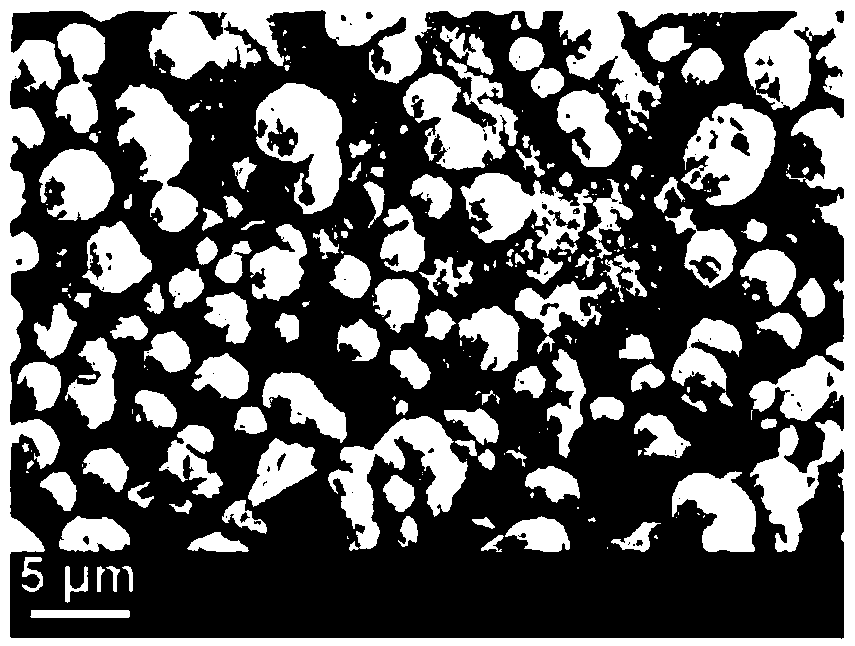

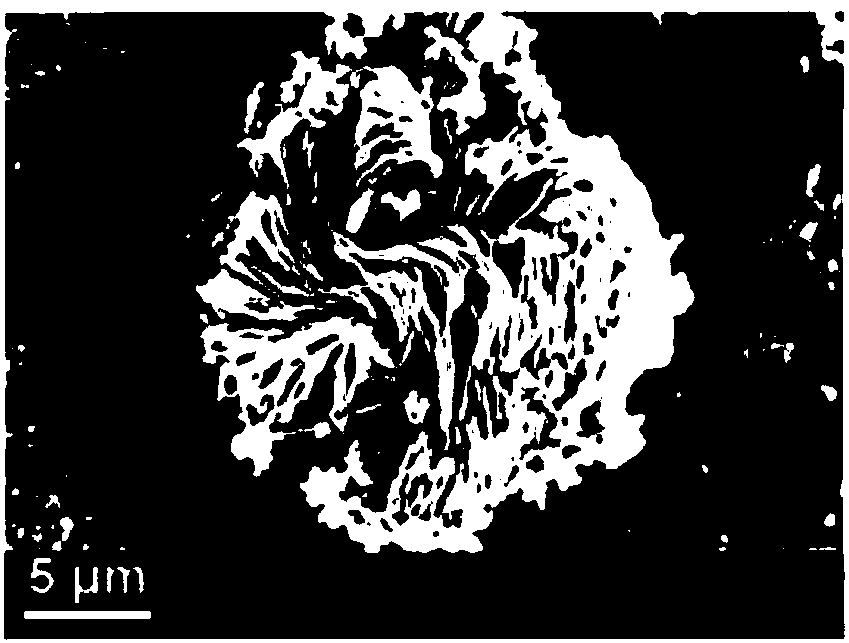

[0047] In Examples 1-9, linear or three-arm star-shaped PLLA and PDLA functionalized with UPy end groups are dissolved in good solvents such as dichloromethane, chloroform, tetrahydrofuran, etc. in a certain mass ratio, so that the concentration of the polymer solution is 1 mg / mL. After stirring and mixing for 2 hours, add dropwise into poor solvents such as ethanol and methanol, and stir until the volume fraction of poor solvents is 20% to 90%, and drop it off after 4 hours. Then after stirring for 24 h, it was centrifuged and washed to collect the solid precipitate. After the solid precipitate was vacuum-dried at 60° C. for 6 h, biodegradable supramolecular PLA microspheres were obtained.

[0048] In Comparative Examples 1 and 2, the same method was used to prepare PLA particles using hydroxyl end-functionalized linear or three-arm star-shaped PLLA, PDLA or a mixture of the two as raw materials. The proportion of PLLA and PDLA in Examples 1-9 and Comparative Examples 1-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com