A kind of halogen-free low-smoke elastomer cable material and preparation method thereof

A technology of elastomer and cable material, applied in the field of halogen-free low-smoke elastomer cable material and its preparation, to achieve good heat resistance, wide range, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

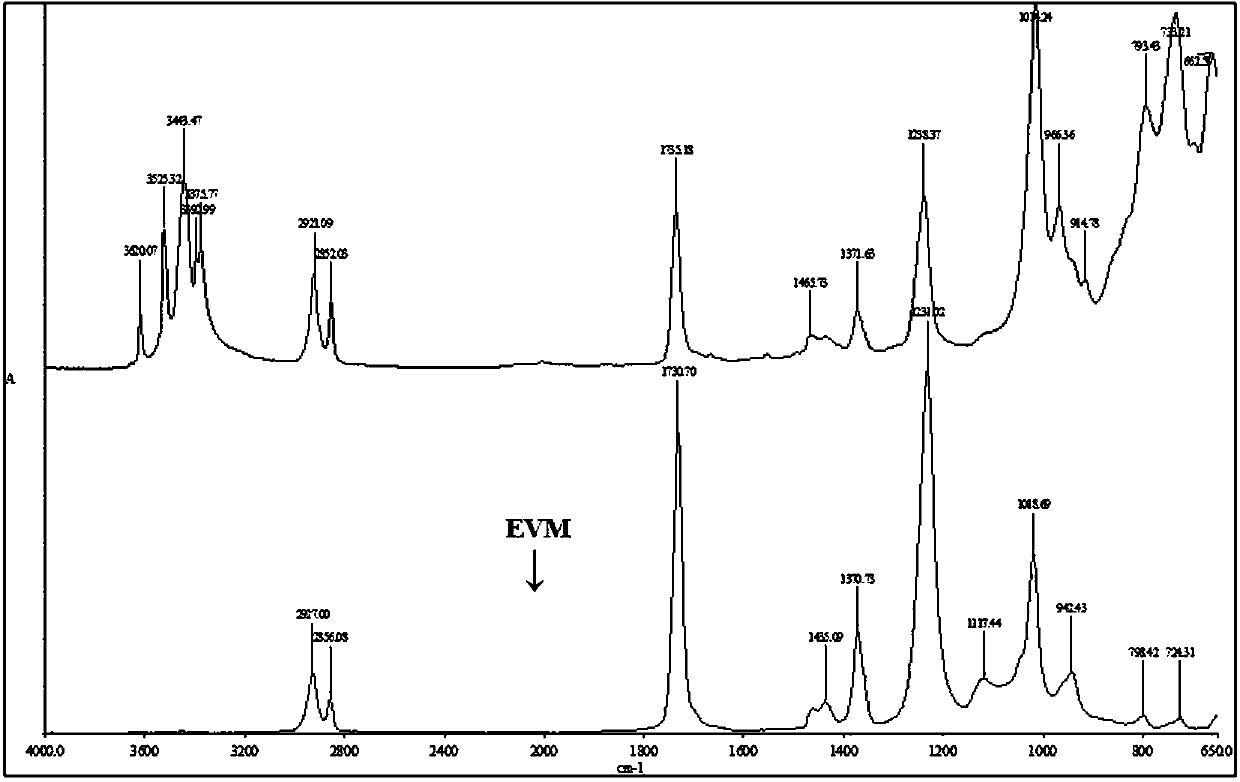

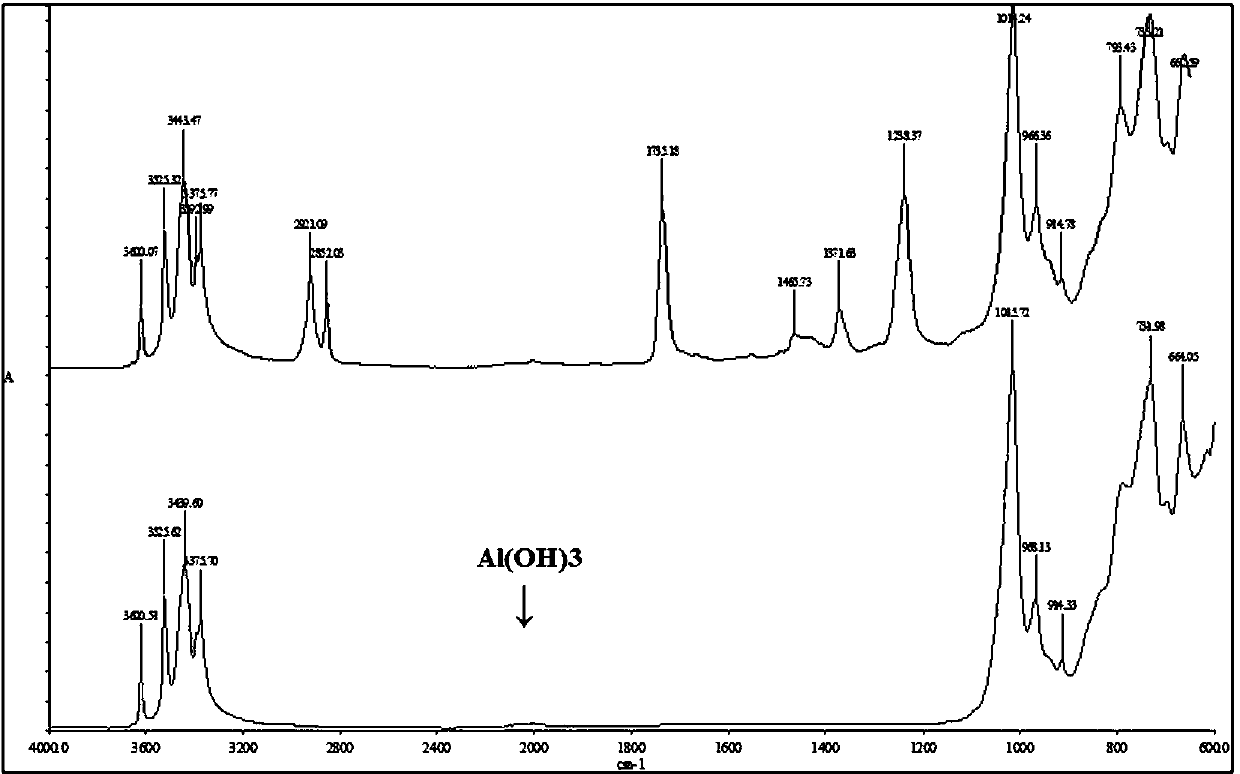

Image

Examples

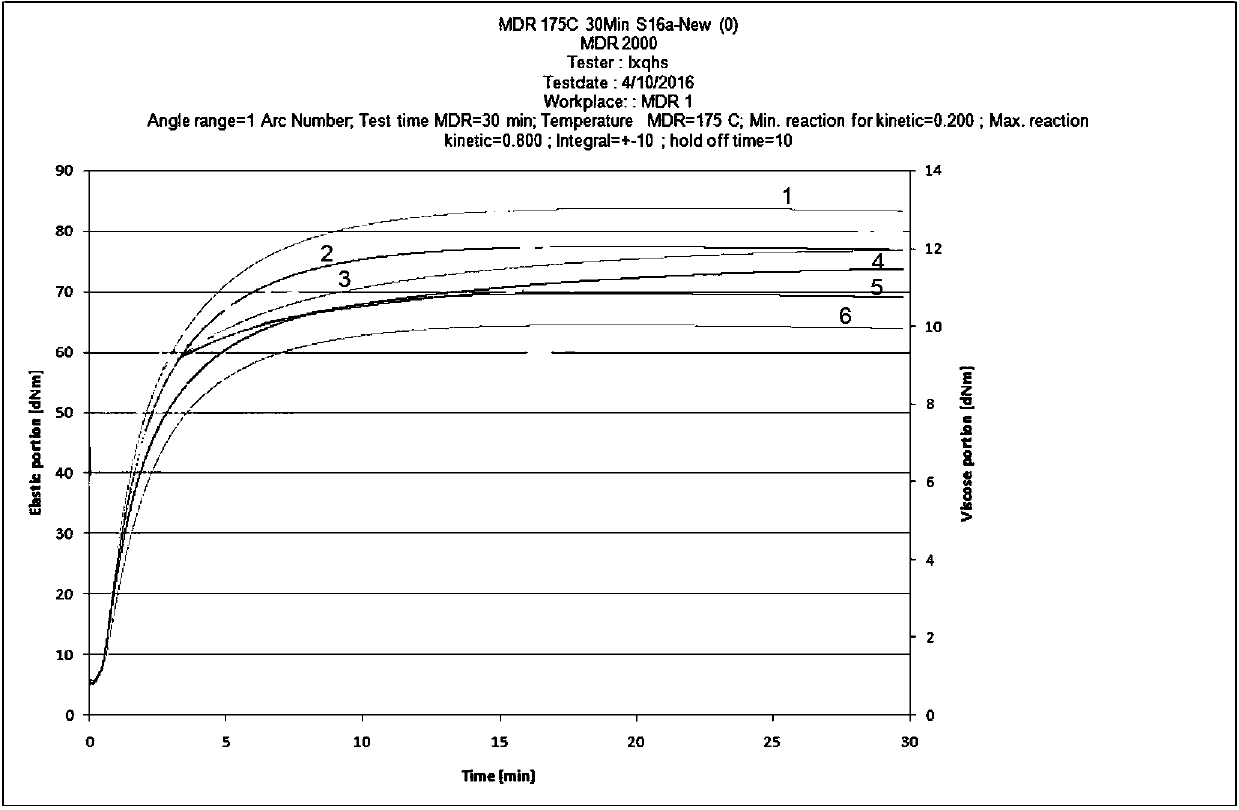

Embodiment 1~6

[0022] Embodiments 1-6 carry out proportioning according to the parts by weight in Table 1.

[0023] Table 1 Component distribution ratio (parts by weight) of each embodiment.

[0024]

[0025] EVM500 is a copolymer of ethylene-vinyl acetate, with a maximum service temperature of 175°C, which not only enhances the stability of the insulating layer, but also makes the cable material have heat aging resistance and excellent electrical insulation properties.

[0026] The halogen-free low-smoke elastomer cable material of the present invention is made of a blend of ethylene-vinyl acetate copolymer elastomer, inorganic flame retardant, reinforcing agent, etc.; the prepared halogen-free low-smoke elastomer cable The material has excellent resilience, high and low temperature resistance, oil resistance, ultraviolet resistance, ozone resistance and weather resistance, and its temperature resistance range can reach between +150°C and -40°C. The finished cable made of this cable mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com