Mold material for injection molding of automobile handle and preparation method thereof

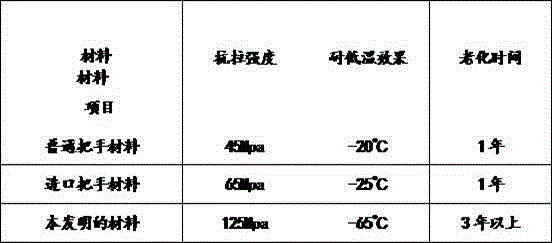

An injection molding and mold material technology, which is applied in the field of mold materials for injection molding of automobile handles and their preparation, can solve the problems of low structural strength, low temperature resistance, and short service life, and achieves improved structural strength and long service life. , Good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A mold material for injection molding of automobile handles, made of the following materials in parts by weight, including 45 parts of polypropylene, 38 parts of polyurethane, 7 parts of epoxy resin, 6 parts of nano-alumina, 10 parts of bamboo charcoal powder, coke Phosphate 8 parts, glass fiber 9 parts, methyl methacrylate 13 parts, silicon micropowder 12 parts, pure acrylic emulsion 9 parts, melamine 22 parts, benzoyl peroxide 10 parts, tert-butyl peroxide benzoate 8 parts , 12 parts of carbon black, 9 parts of paraffin, 22 parts of diethylene glycol monobutyl ether adipate, 18 parts of silicone rubber and 13 parts of silicon dioxide.

[0019] A kind of preparation method of the mold material of injection molding of automobile handle, comprises the following steps:

[0020] 1) 45 parts of polypropylene, 38 parts of polyurethane, 7 parts of epoxy resin, 6 parts of nano-alumina, 10 parts of bamboo charcoal powder, 8 parts of pyrophosphate, 9 parts of glass fiber, 13 par...

Embodiment 2

[0026] A mold material for injection molding of automobile handles, made of the following materials in parts by weight, including 50 parts of polypropylene, 40 parts of polyurethane, 10.5 parts of epoxy resin, 8 parts of nano-alumina, 11 parts of bamboo charcoal powder, coke Phosphate 11.5 parts, glass fiber 12.5 parts, methyl methacrylate 15.5 parts, silicon micropowder 13 parts, pure acrylic emulsion 12.5 parts, melamine 23 parts, benzoyl peroxide 12.5 parts, tert-butyl peroxybenzoate 9 parts , 13.5 parts of carbon black, 12.5 parts of paraffin, 23 parts of diethylene glycol monobutyl ether adipate, 19 parts of silicone rubber and 15.5 parts of silicon dioxide.

[0027] A kind of preparation method of the mold material of injection molding of automobile handle, comprises the following steps:

[0028] 1) 50 parts of polypropylene, 40 parts of polyurethane, 10.5 parts of epoxy resin, 8 parts of nano-alumina, 11 parts of bamboo charcoal powder, 11.5 parts of pyrophosphate, 12.5...

Embodiment 3

[0034]A mold material for injection molding of automobile handles, made of the following materials in parts by weight, including 55 parts of polypropylene, 42 parts of polyurethane, 14 parts of epoxy resin, 10 parts of nano-alumina, 12 parts of bamboo charcoal powder, coke 15 parts of phosphate, 16 parts of glass fiber, 18 parts of methyl methacrylate, 14 parts of silicon micropowder, 16 parts of pure acrylic emulsion, 24 parts of melamine, 15 parts of benzoyl peroxide, 10 parts of tert-butyl peroxybenzoate , 17 parts of carbon black, 16 parts of paraffin, 24 parts of diethylene glycol monobutyl ether adipate, 20 parts of silicone rubber and 18 parts of silicon dioxide.

[0035] A kind of preparation method of the mold material of injection molding of automobile handle, comprises the following steps:

[0036] 1) 55 parts of polypropylene, 42 parts of polyurethane, 14 parts of epoxy resin, 10 parts of nano-alumina, 12 parts of bamboo charcoal powder, 15 parts of pyrophosphate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com