TPE (thermoplastic elastomer) material for manufacturing refrigerator sealing rubber strips and preparation process of TPE material

A sealing strip and preparation technology, applied in the field of TPE elastomers, can solve the problems of easy breeding of bacteria, high humidity, mildew of the sealing strip, etc., and achieve the effects of reducing material mildew, strong antibacterial ability, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

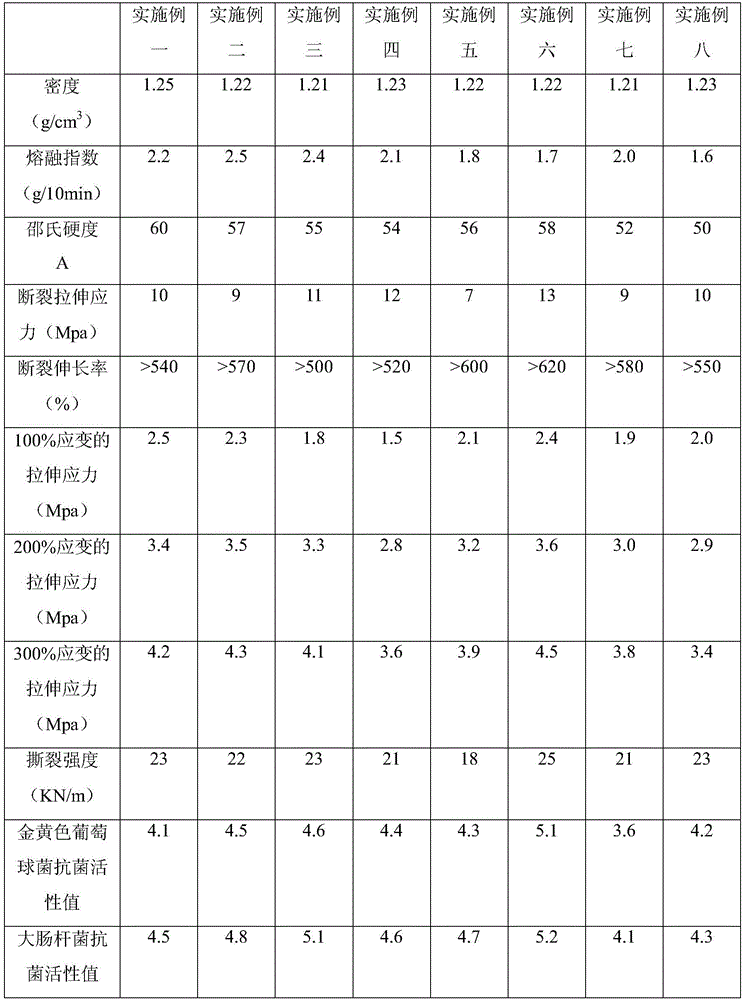

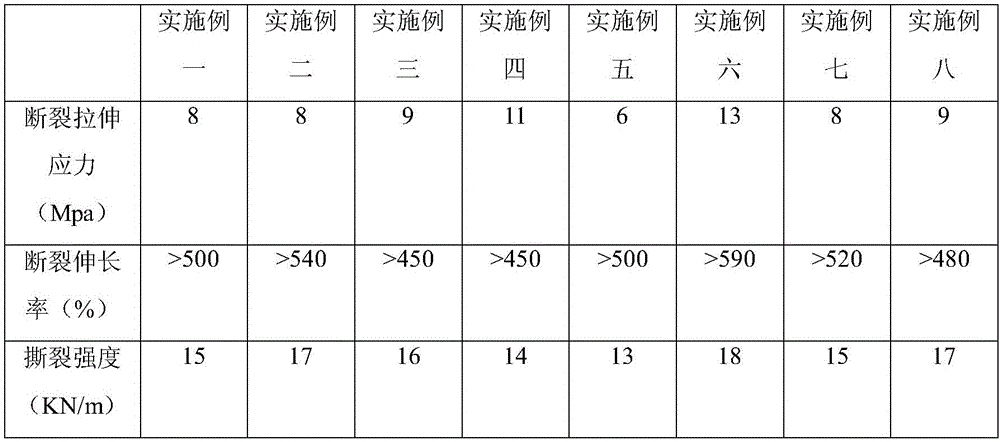

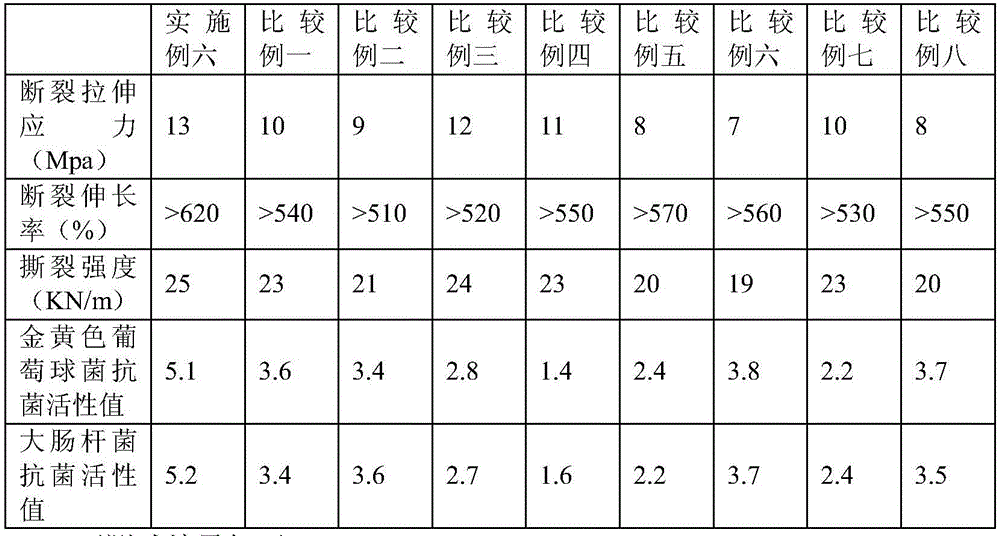

Examples

Embodiment 1

[0048] (1) Select the following components and their mass parts: 100 parts of SEPS4033 and 100 parts of white oil 26#, set the speed of 600r / min in the high-speed mixer and mix for 3min;

[0049] (2) Add the following components and mass parts thereof to the material mixed in step (1): 40 parts of random copolymerized polypropylene, 200 parts of calcium carbonate, 1 part of polyquaternium salt, 2 parts of silver-loaded zeolite, 2 parts of nano-titanium dioxide, 2 parts of olive leaf extract, 5 parts of methyl methacrylate-butadiene-styrene copolymer, 4.5 parts of maleic anhydride grafted PP, 0.4 parts of stabilizer, set the speed at 1200r / min and mix for 3min ;

[0050] (3) Set the temperature inside the barrel of the twin-screw extruder with an aspect ratio of 48:1: 170°C for the first zone, 180°C for the second zone, 180°C for the third zone, 180°C for the fourth zone, 180°C for the fifth zone, and 180°C for the sixth zone ℃, seven zone 180 ℃, eight zone 180 ℃, head 180 ℃; ...

Embodiment 2

[0053] (1) Select the following components and their mass parts: 200 parts of SEPS4033 and 200 parts of white oil 32#, set the speed in the high-speed mixer at 800r / min and mix for 2min;

[0054] (2) Add the following components and mass parts thereof to the material mixed in step (1): 80 parts of random copolymerized polypropylene, 220 parts of calcium carbonate, 5 parts of polyquaternium salt, 4 parts of silver-loaded zeolite, 3 parts of nano-titanium dioxide, 3 parts of olive leaf extract, 4 parts of methyl acrylate-ethyl acrylate polymer, 5 parts of maleic anhydride grafted PP, 0.7 parts of stabilizer, set the speed at 1500r / min and mix for 2min;

[0055] (3) Set the temperature inside the barrel of the twin-screw extruder with an aspect ratio of 44:1: 170°C in the first zone, 180°C in the second zone, 180°C in the third zone, 180°C in the fourth zone, 180°C in the fifth zone, and 180°C in the sixth zone ℃, 180℃ in the seventh zone, 180℃ in the eighth zone, and 190℃ in the...

Embodiment 3

[0058] (1) Select the following components and their mass parts: 150 parts of SEPS4044 and 200 parts of white oil 26#, set the speed of rotation at 750r / min in the high-speed mixer and mix for 2.2min;

[0059] (2) Add the following components and mass parts thereof to the material mixed in step (1): 60 parts of random copolymerized polypropylene, 270 parts of calcium carbonate, 2 parts of polyquaternium salt, 3 parts of silver-loaded zeolite, 4 parts of nano-titanium dioxide, 4 parts of olive leaf extract, 1 part of methyl acrylate-ethyl acrylate polymer, 2.5 parts of maleic anhydride grafted PP, 0.6 parts of stabilizer, set the rotation speed at 1400r / min and mix for 2.2min;

[0060] (3) Set the temperature inside the barrel of the twin-screw extruder with an aspect ratio of 48:1: 170°C in the first zone, 190°C in the second zone, 190°C in the third zone, 190°C in the fourth zone, 190°C in the fifth zone, and 190°C in the sixth zone ℃, 190℃ in the seventh zone, 190℃ in the ei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com