High specific gravity high-dispersibility and anti-impact ABS (Acrylonitrile Butadiene Styrene) material and preparation method thereof

An ABS material with high dispersibility technology, which is applied in the field of high specific gravity, impact-resistant ABS material and its preparation, and high dispersibility. It can solve the problems of poor dispersibility with modifiers and poor processing fluidity of ABS resin. Achieve the effects of avoiding appearance defects, improving activity and dispersibility, and promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

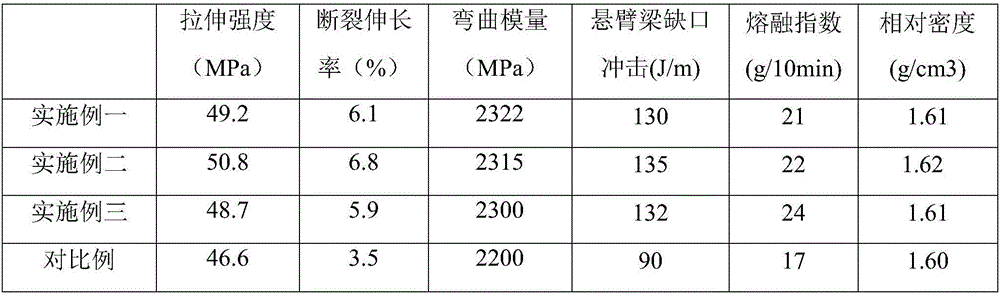

Embodiment 1

[0023] The present embodiment provides a kind of preparation method of high specific gravity, high dispersibility, impact-resistant ABS material, and its preparation method comprises the following steps:

[0024] The first step: add metallocene LLDPE 1500g, barium sulfate 8000g, toughener EPDM rubber 200g, ethylene bisstearamide and magnesium stearate 150g each into a high-speed mixer and mix for 4 minutes to obtain a pre-filling masterbatch mix;

[0025] The second step: put the filler masterbatch premix in the first step into the twin-screw extruder to extrude and granulate. The processing temperature of the extruder is 180°C, the screw speed is 300r / min, and the feeding speed is 15HZ. The length-to-diameter ratio of the twin-screw extruder screw is 40:1, after melting, extrusion, cooling, pelletizing, drying, the filling masterbatch product can be obtained;

[0026] The third step: Add 2500g of the filler masterbatch in the second step, 4700g of ABS, 2500g of precipitated ba...

Embodiment 2

[0029] The difference between this embodiment and the first embodiment is that in the third step, 3000 g of masterbatch, 4600 g of ABS and 2100 g of precipitated barium sulfate are filled.

Embodiment 3

[0031] The difference between the present embodiment and the first embodiment is that in the third step, 3500 g of masterbatch, 4500 g of ABS and 1700 g of precipitated barium sulfate are filled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com