Soft and transparent silk fibroin membrane and preparation method thereof

A technology of silk fibroin and transparent silk, which is applied in the field of transparent film materials and their preparation, can solve the problems of difficulty in being transparent and soft, the cytotoxicity of small molecular substances is high, and it is difficult to fully meet the requirements for the use of biological materials, so as to maintain biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a kind of silk fibroin / urea blend film, and preparation method comprises the following steps:

[0022] 1. Silkworm silk uses 0.5 M NaHCO 3 -Na 2 CO 3 Buffer solution (pH value = 9), boiled repeatedly at 98-100°C for 30 minutes each time, washed with deionized water, and repeated the above operation three times. Dissolve the degummed and dried silk fibers in 9.3M lithium bromide solution at a bath ratio of 1:10 at 60°C, add a double-layer dialysis bag with a molecular weight cut-off of 10,000 Daltons after cooling (the dialysis bag is covered with another Layer dialysis bag, forming a double-layer dialysis bag), dialyzed with deionized water for 3 days to obtain a purified silk fibroin solution.

[0023] 2. Configure 100 mg / mL urea solution, and mix urea and silk fibroin according to the mass ratio (m URE / m SF ): 1.7 / 10 blending, pouring the blended silk fibroin solution into a polystyrene mold, blowing and drying at 25°C and 75% humidity f...

Embodiment 2

[0030] 1. Silkworm silk uses 0.3 M NaHCO 3 -Na 2 CO 3 Buffer solution (pH value = 9), boiled repeatedly at 98-100°C for 30 minutes each time, washed with deionized water, and repeated the above operation three times. Dissolve the degummed and dried silk fiber in 9.3M lithium bromide solution at a bath ratio of 1:10 at 63°C, add a double-layer dialysis bag with a molecular weight cut-off of 10,000 Daltons after cooling (the dialysis bag is covered with another Layer dialysis bag, forming a double-layer dialysis bag), dialyzed with deionized water for 3 days to obtain a purified silk fibroin solution.

[0031] 2. Configure 80 mg / mL urea solution, mix urea and silk fibroin according to the mass ratio (m URE / m SF ): 2 / 10 blending, and then pour the blended silk fibroin solution into a polystyrene mold, blow dry and balance for 48 hours at 25°C and 65% humidity to obtain an insoluble soft transparent silk fibroin film.

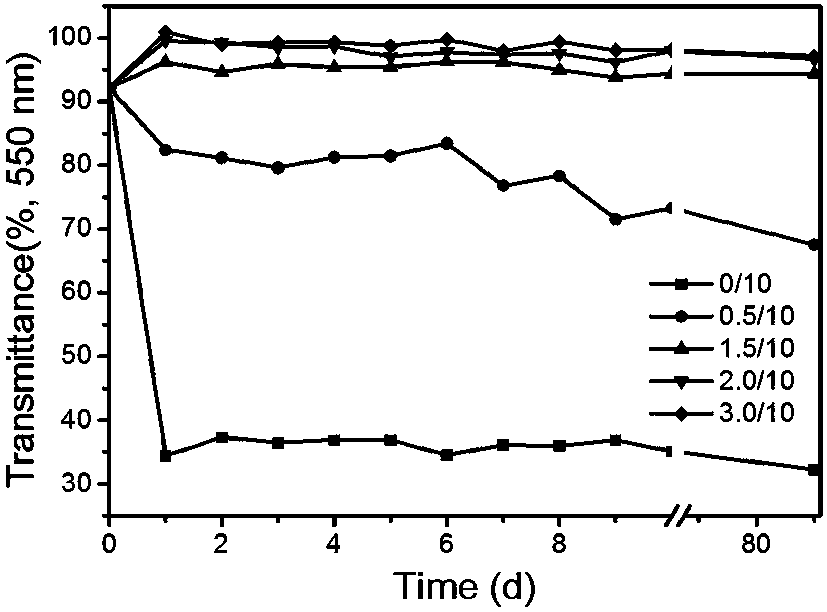

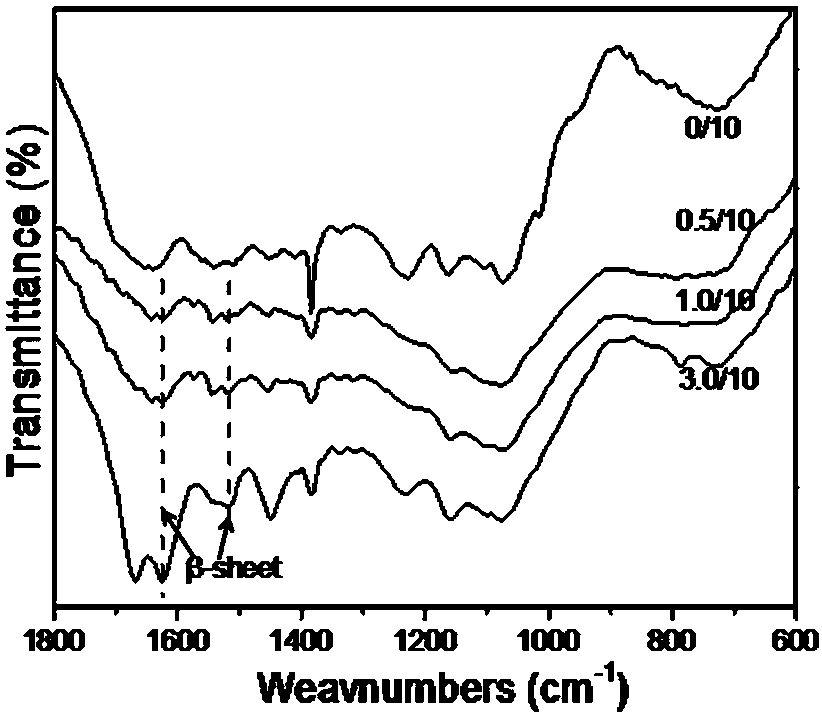

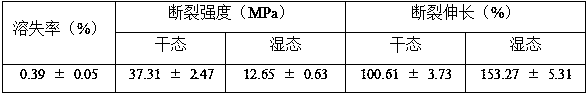

[0032]The resulting silk fibroin / urea blend film was te...

Embodiment 3

[0038] 1. Silkworm silk uses 0.7 M NaHCO 3 -Na 2 CO 3 The buffer solution (pH value = 9) was repeatedly boiled at 98-100°C for 28 minutes each time, washed with deionized water, and the above operation was repeated three times. Dissolve the degummed and dried silk fibers in 9.3M lithium bromide solution at a bath ratio of 1:10 at 58°C, add a double-layer dialysis bag with a molecular weight cut-off of 10,000 Daltons after cooling (the dialysis bag is covered with another Layer dialysis bag, forming a double-layer dialysis bag), dialyzed with deionized water for 3 days to obtain a purified silk fibroin solution.

[0039] 2. Configure 300 mg / mL urea solution, and mix urea and silk fibroin according to the mass ratio (m URE / m SF ): 3 / 10 blending, and then pour the blended silk fibroin solution into a polystyrene mold, blow dry and balance at 22°C and 60% humidity for 48 hours to obtain an insoluble soft transparent silk fibroin film. Its dry light transmittance was measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com