A kind of anti-oxygen barrier effect UV-curable coating and preparation method thereof

A technology for curing coatings and ultraviolet light, applied in epoxy resin coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve heating and other problems, and achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (1) Preparation of DPTS: Dissolve equimolar amounts of 4-dimethylaminopyridine and p-toluenesulfonic acid in hot toluene (80°C) respectively, mix and stir for 15 minutes, then cool to room temperature, and a large amount of white solid precipitates, which are After suction filtration and vacuum drying (the drying temperature is 50°C and the drying time is 12 hours), a white crystalline powder, namely DPTS, is obtained;

[0031] (2) Preparation of mercapto-terminated hyperbranched polyester

[0032] In the there-necked flask equipped with mechanical stirring, thermometer, reflux condenser and water separator, add 8.75g hyperbranched polyester Boltorn H20 (manufacturer is Swedish Perstorp AB company, molecular weight 1750, hydroxyl number is 16), 8.38g mercapto Acetic acid, 0.2g DPTS and 100ml toluene, heated in an oil bath, reflux at 120°C to separate the water, stop the reaction after reaching the theoretical water output (theoretical water output refers to the water ou...

Embodiment 1

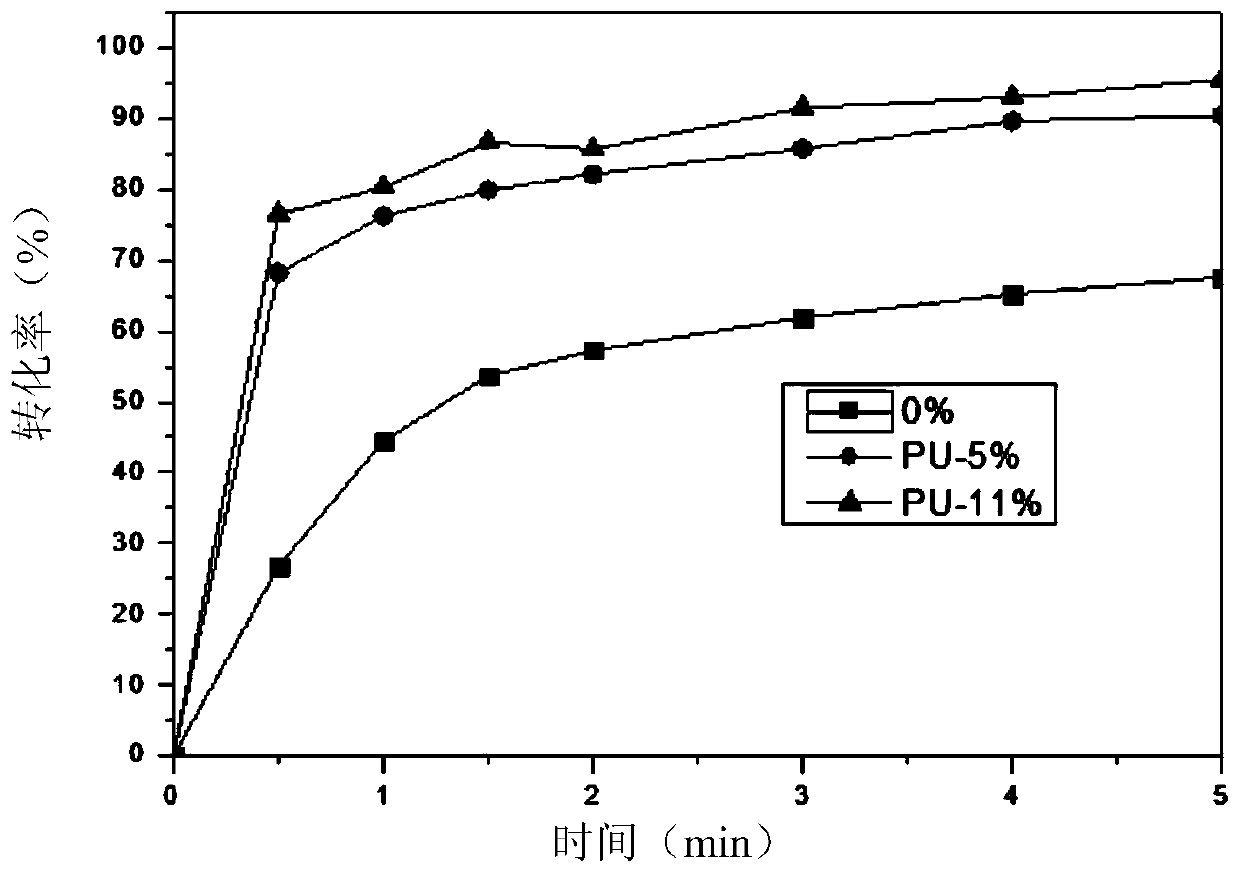

[0034] A UV curable coating with anti-oxygen barrier effect is obtained by the following method: each component is counted in parts by weight: 80 parts of aliphatic polyurethane acrylic resin (its model is 3210, the manufacturer is Zhongshan Ketian Electronic Material Co., Ltd. ), 20 parts of hexanediol diacrylate, 3 parts of 2-hydroxyl-2-methyl-phenylacetone-1, 5 parts of mercapto-terminated hyperbranched polyester H20-SH, stir to obtain the coating, denoted as PU-5%.

Embodiment 2

[0036] A UV curable coating with anti-oxygen barrier effect is obtained by the following method: each component is counted in parts by weight: 80 parts of aliphatic polyurethane acrylic resin (its model is 3210, the manufacturer is Zhongshan Ketian Electronic Material Co., Ltd. ), 20 parts of hexanediol diacrylate, 3 parts of 2-hydroxyl-2-methyl-phenylacetone-1, 11 parts of mercapto-terminated hyperbranched polyester H20-SH, stir to obtain the coating, denoted as PU-11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com