Method using klebsiella pneumoniae to produce xylonic acid

A technology of pneumonia bacillus and xylonic acid, which is applied in the biological field to achieve the effects of high production intensity, high final product concentration and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The gene recombination method is used to inactivate the Klebsiella pneumoniae gluconate dehydrogenase gene to realize the inactivation of the glucose dehydrogenase activity.

[0026] Klebsiella pneumoniae in this embodiment adopts the bacterial strain of numbering CGMCC 1.6366 (this bacterial strain is also referred to as TUAC01 or ACO1), and the bacterial strain of CGMCC 1.6366 has been disclosed in the authorized invention patent ZL201210093993, and also in the open literature (Wei Dong, Wang This strain has also been disclosed in Min, Shi Jiping, Hao Jian. Red recombinase assisted gene replacement in Klebsiellapneumoniae. Journal of Industrial Microbiology & Biotechnology. 2012 39:1219-1226). This strain is a strain used to produce 1,3-propanediol, 2,3-butanediol, acetoin and 2-ketogluconic acid. The bacterium was isolated from soil, and the isolation process and traits are described in open literature (Hao Jian, et al. Isolation and characterization of microorganism...

Embodiment 2

[0044] The Klebsiella pneumoniae bacterial strain Kp-gad that the gluconate dehydrogenase activity obtained in wild-type bacterial strain Klebsiella pneumoniae and embodiment 1 is eliminated - Shake flask batch fermentation experiments were performed.

[0045] The Klebsiella pneumoniae bacterial strain Kp-gad that the gluconate dehydrogenase activity obtained in the wild-type bacterial strain Klebsiella pneumoniae CGMCC 1.6366 and embodiment 1 is eliminated - They were respectively inoculated into 250ml Erlenmeyer flasks containing 50ml xylose acid fermentation medium, the rotation speed of the shaker cabinet was 200 rpm, and the aerobic fermentation was carried out at a constant temperature of 25°C.

[0046] The components of the fermentation medium are: xylose 5g / L, corn steep liquor 0.5g / L, calcium carbonate 1g per bottle.

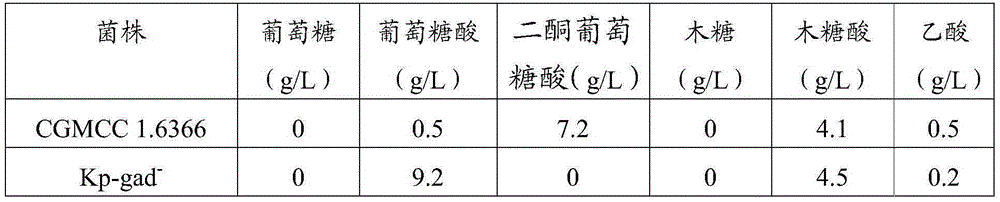

[0047] After culturing for 24 hours, the components in the fermentation broth were determined. It is determined by liquid chromatography, and the com...

Embodiment 3

[0052] The Klebsiella pneumoniae bacterial strain Kp-gad that the gluconate dehydrogenase activity obtained in wild-type bacterial strain Klebsiella pneumoniae and embodiment 1 is eliminated - Performing shake flask batch fermentation experiments

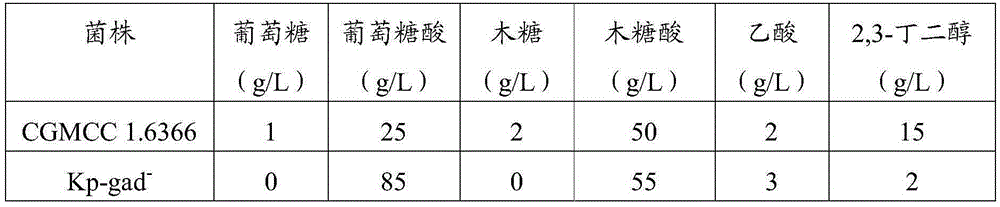

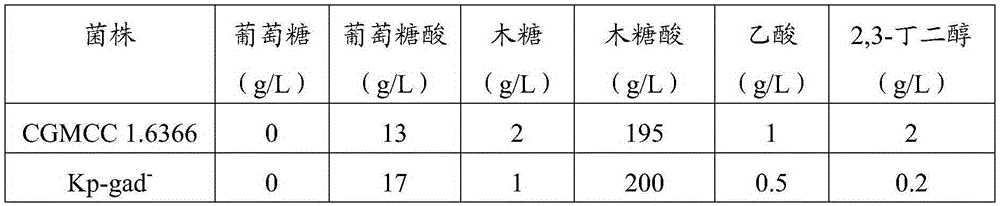

[0053] Kp-gad obtained in the wild-type bacterial strain Klebsiella pneumoniae CGMCC 1.6366 and embodiment 1 - Inoculate into 250ml Erlenmeyer flask respectively, wherein the fermentation medium of the mixture of 50ml glucose and xylose is housed, shake the bottle cabinet rotating speed 200 revs per minute, constant temperature 45 ℃ carry out aerobic fermentation culture.

[0054] The medium components are: glucose 10g / L, xylose 5g / L, yeast extract 0.5g / L, calcium carbonate 1g per bottle.

[0055] After culturing for 24 hours, the components in the fermentation broth were determined. The product was detected by the method in Example 2. Gluconic acid and gluconate are not distinguished in the present invention, and xylose and xylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com