Lithium-manganese-rich laminated anode material for lithium ion battery and preparation method thereof

A technology for lithium ion batteries and cathode materials, which is applied in the field of electrochemical materials, can solve the problems of discharge voltage platform decay, poor structural stability, and insufficient structural stability, and achieves the effects of improving discharge voltage, structural stability, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

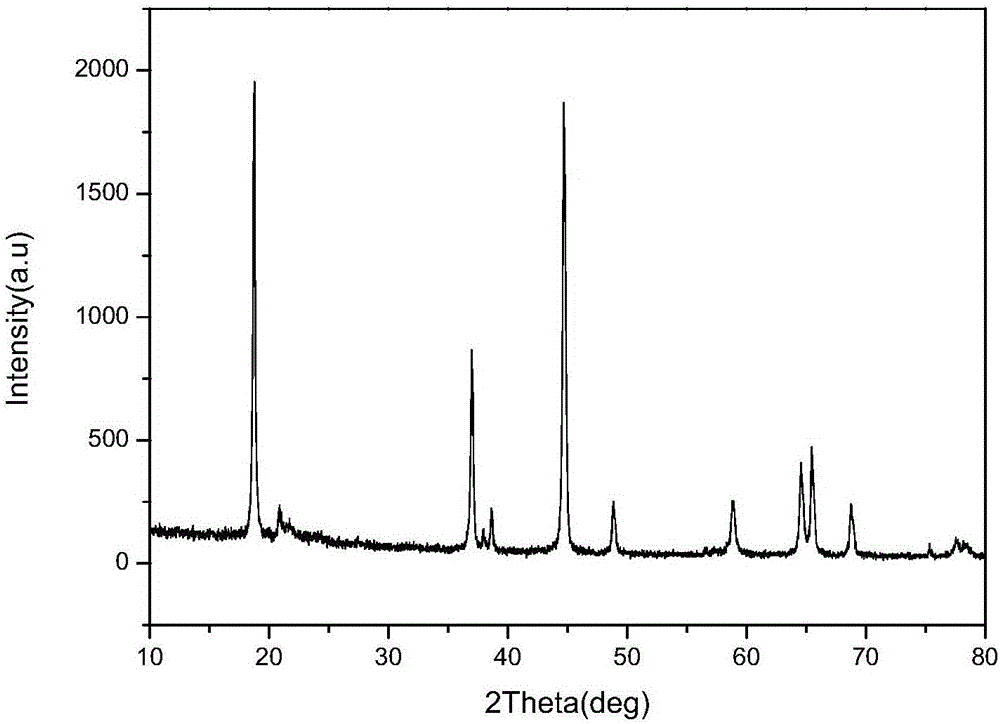

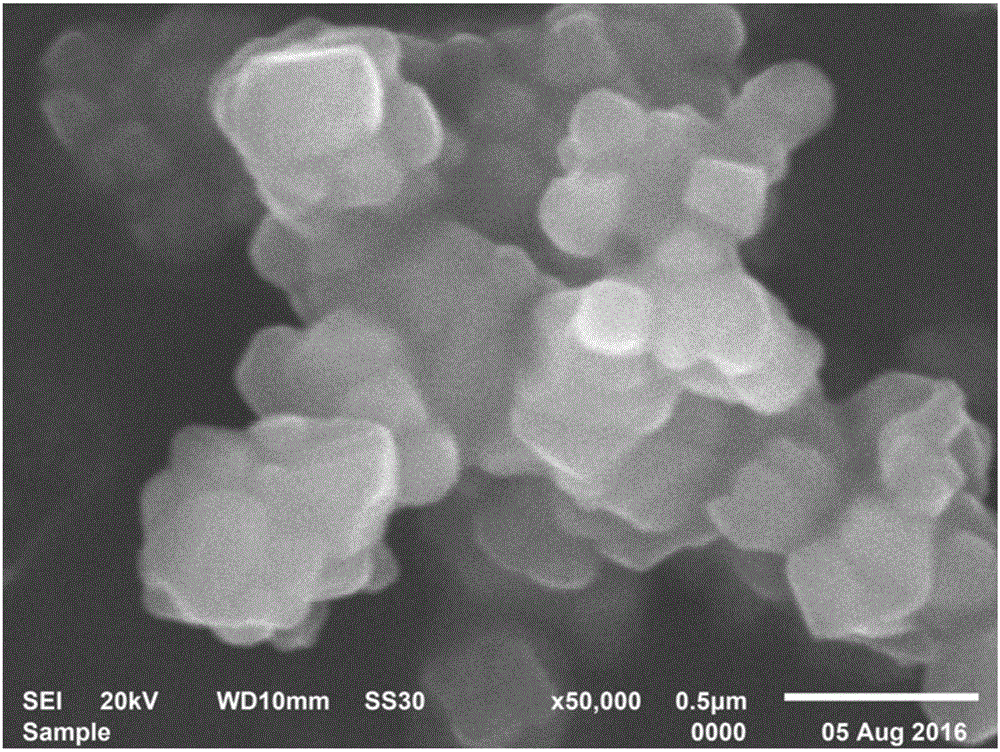

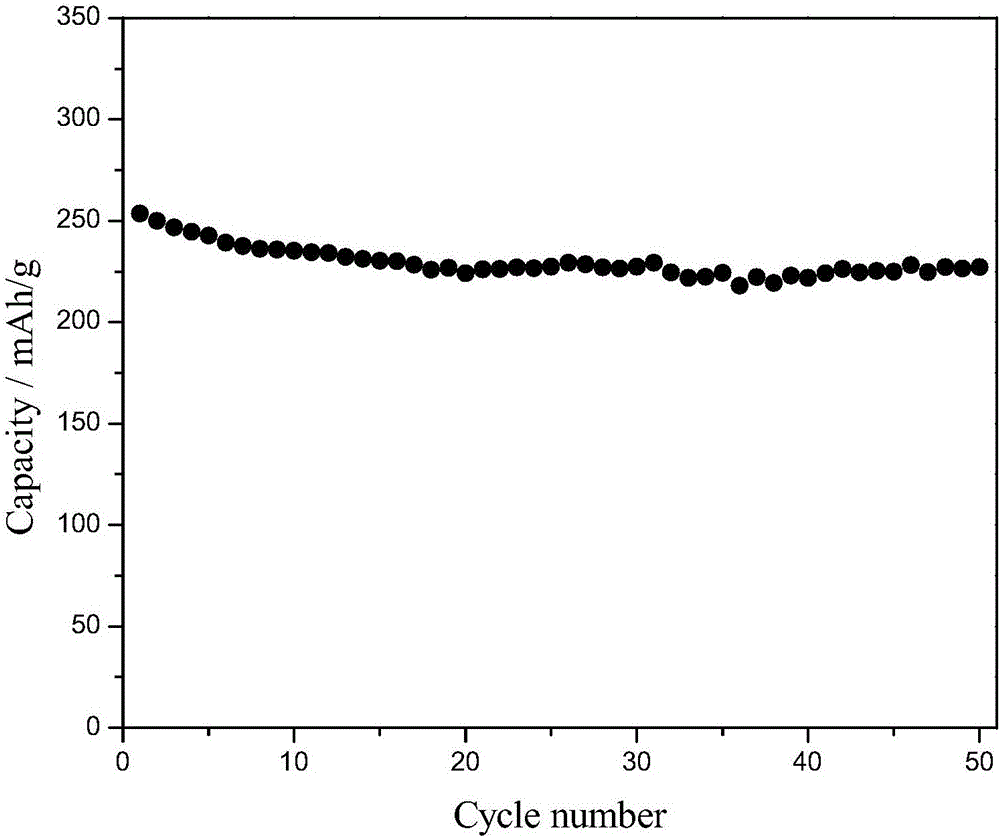

[0030] The present embodiment provides a lithium-rich manganese layered positive electrode material for a lithium ion battery, the molecular formula of which is 0.4Li 2 mn 0.6 sn 0.2 Ru 0.2 o 3 0.6LiNi 0.4 mn 0.4 co 0.2 o 2 , its preparation method comprises the following steps:

[0031] S1, dissolving stannous acetate, ruthenium chloride, nickel acetate, cobalt acetate and manganese acetate with a molar ratio of 0.065:0.065:0.2:0.1:0.4 in deionized water to form 0.2mol / L (calculated based on the total amount of metal ions) mixed solution of metal ions;

[0032] S2, drop the metal ion mixed solution into 0.2mol / L oxalic acid solution (compared to the metal ion, oxalic acid is excessive 5%), the dropping rate is 3mL / min, use ammonia water to control the pH value to about 7 during the dropping process , reacted to obtain a precipitate, filtered, washed three times with deionized water, and dried at 80°C to obtain a precursor;

[0033] S3, combining the precursor with e...

Embodiment 2

[0037] The present embodiment provides a lithium-rich manganese layered positive electrode material for a lithium ion battery, the molecular formula of which is: 0.6Li 2 mn 0.8 sn 0.1 Ru 0.1 o 3 0.4LiNi 0.4 mn 0.4 co 0.2 o 2 , its preparation method comprises the following steps:

[0038] S1, dissolving stannous acetate, ruthenium chloride, nickel acetate, cobalt acetate and manganese acetate with a molar ratio of 0.045:0.045:0.12:0.06:0.49 in deionized water to form 0.3mol / L (calculated based on the total amount of metal ions) mixed solution of metal ions;

[0039] S2, drop the metal ion mixed solution into 0.3mol / L oxalic acid solution (compared to the metal ion, the oxalic acid excess is 5%), the dropping rate is 5mL / min, use ammonia water to control the pH value to about 7 during the dropping process , reacted to obtain a precipitate, filtered, washed three times with deionized water, and dried at 80°C to obtain a precursor;

[0040] S3, combining the precursor w...

Embodiment 3

[0044] This embodiment provides a lithium-rich manganese layered positive electrode material for lithium ion batteries, the molecular formula of which is: 0.5Li 2 mn 0.7 sn 0.15 Ru 0.15 o 3 0.5LiNi 0.4 mn 0.4 co 0.2 o 2 . Its preparation method comprises the following steps:

[0045] S1, dissolving stannous acetate, ruthenium chloride, nickel acetate, cobalt acetate and manganese acetate with a molar ratio of 0.06:0.06:0.16:0.08:0.44 in deionized water to form 0.15mol / L (calculated based on the total amount of metal ions) mixed solution of metal ions;

[0046] S2, drop the metal ion mixed solution into 0.15mol / L oxalic acid solution (compared to the metal ion, oxalic acid is excessive 5%), the dropping rate is 8mL / min, use ammonia water to control the pH value to about 7 during the dropping process , reacted to obtain a precipitate, filtered, washed three times with deionized water, and dried at 80°C to obtain a precursor;

[0047]S3, combining the precursor with ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com