Silver particle coating composition

A technology of composition and silver particles, which is applied in the field of coating compositions containing silver particles, can solve the problems of undisclosed, inability to obtain sufficient electrical conductivity, etc., and achieve the effects of excellent adhesion, excellent electrical conductivity, and excellent drawing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

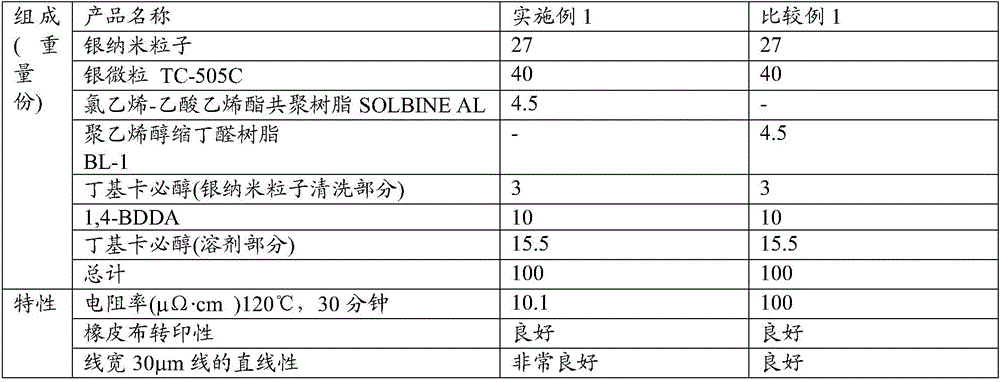

Embodiment 1

[0227] (Preparation of silver nanoparticles)

[0228] 40.0 g (0.1317 mol) of silver oxalate was placed in a 500 mL flask, and 60 g of n-butanol was added thereto to prepare a n-butanol slurry of silver oxalate. An amine mixed solution of 115.58 g (1.5802 mol) of n-butylamine, 51.06 g (0.3950 mol) of 2-ethylhexylamine, and 17.02 g (0.1317 mol) of n-octylamine was added dropwise to this slurry at 30°C. After dripping, it stirred at 30 degreeC for 1 hour, and the complex formation reaction of silver oxalate and an amine advanced. After the silver oxalate-amine complex was formed, heating was performed at 110° C. to thermally decompose the silver oxalate-amine complex to obtain a suspension of dark blue silver nanoparticles suspended in the amine mixture.

[0229] The obtained suspension was cooled, 120 g of methanol was added thereto and stirred, and then, silver nanoparticles were precipitated by centrifugation, and the supernatant was removed. To the silver nanoparticles, 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific resistance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com