Carbon nitride two-dimensional material composite film and preparation method and application thereof

A two-dimensional material, carbon nitride technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as research needs to be enriched, and achieve the effect of high mechanical strength and good selective separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

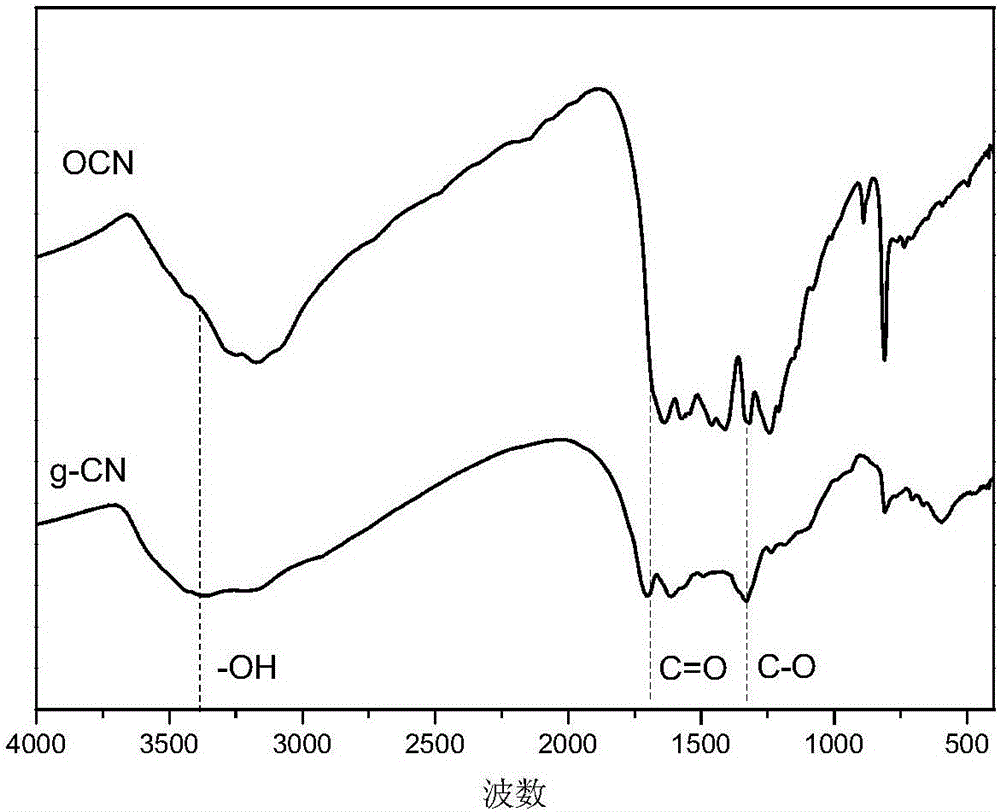

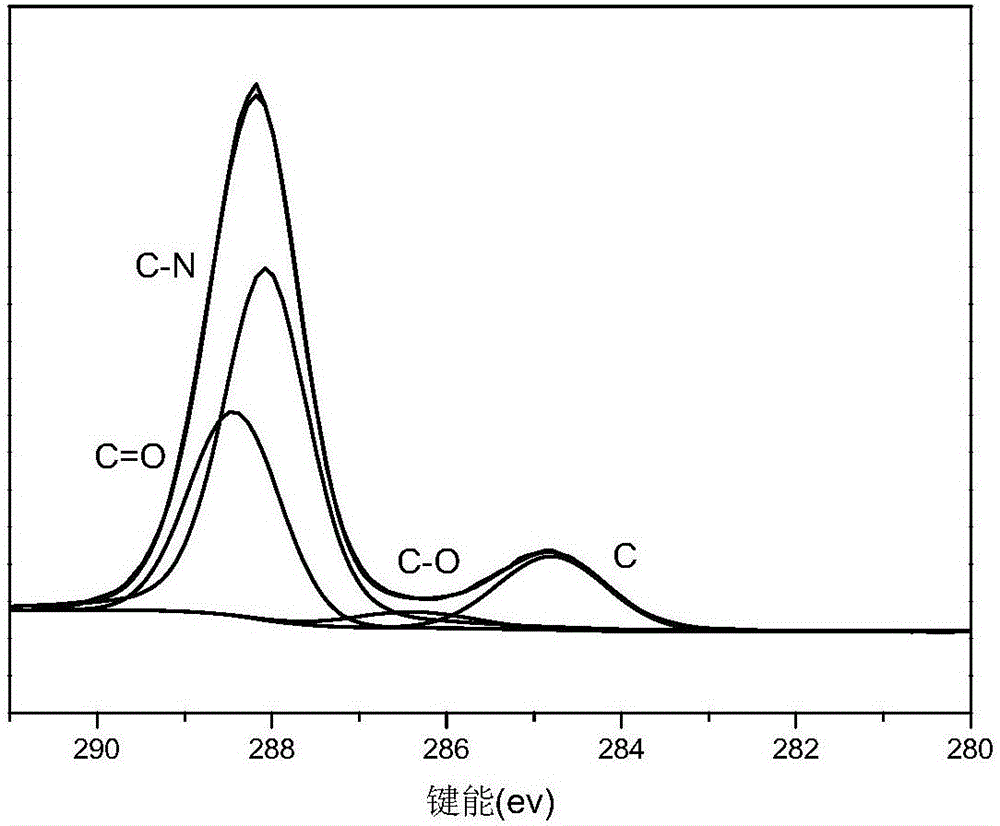

[0046] This example is to prepare a carbon oxide nitride two-dimensional material-polyvinyl alcohol composite membrane on a tubular ceramic support for separating water and a mixture of C2-C4 alcohols.

[0047] In this embodiment, the steps of preparing carbon oxynitride by the hummer method are as follows.

[0048] 1 g of g-C 3 N 4 -0825 powder, add 50ml of concentrated sulfuric acid. Under the condition of ice bath, slowly add 3.5g potassium permanganate. The flask was immersed in a water bath at 35°C, and the reaction was stirred with a magnetic stirrer for 1 hour. Then 200ml of water was slowly added into the flask under the condition of ice bath, and 30% aqueous hydrogen peroxide was added until no more bubbles were generated. The obtained dispersion was centrifuged at 10,000 rpm for 1 hour. The resulting isolate was washed 3 times with deionized water to reach a pH of 7. Then vacuum dry at 50° C. for 12 h. Remember to oxidize carbon nitride.

[0049] The specific...

Embodiment 2

[0056] A carbon oxide nitride two-dimensional material-polydimethylsiloxane composite membrane was prepared on a tubular ceramic support for the separation of water and a mixture of C2-C4 alcohols.

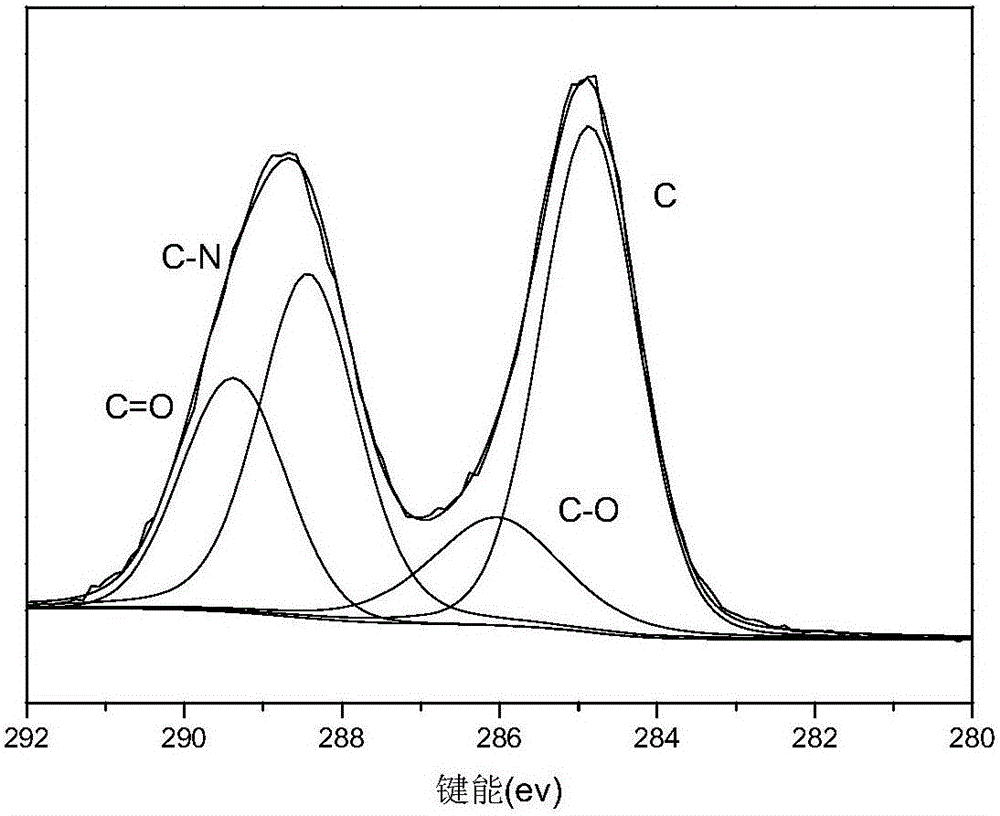

[0057] In the present embodiment, the steps of preparing carbon oxynitride by the hummer method are as follows: 1g of g-C 3 N 4 -0825 powder, add 40ml of concentrated sulfuric acid. Under the condition of ice bath, slowly add 3.5g potassium permanganate. The flask was immersed in a water bath at 45°C, and the reaction was stirred with a magnetic stirrer for 4 hours. Then, under the condition of ice bath, 200ml of water was slowly added into the flask, and 30% aqueous hydrogen peroxide was added into the flask until no more bubbles were generated. The obtained dispersion was centrifuged at 25,000 rpm for 1 hour. The resulting isolate was washed 3 times with deionized water to reach a pH of 7. Then vacuum dry at 50° C. for 12 h.

[0058] In this embodiment, the preparation met...

Embodiment 3

[0065] Carbon oxide nitride two-dimensional material self-assembled membrane prepared on tubular ceramic support for separation of water and C2-C4 alcohol mixture.

[0066] In the present embodiment, the steps of preparing carbon oxynitride by the hummer method are as follows: 1g of g-C 3 N 4 -0825 powder, add 45ml of concentrated sulfuric acid. Under the condition of ice bath, slowly add 3.5g potassium permanganate. The flask was immersed in a water bath at 40°C, and the reaction was stirred with a magnetic stirrer for 3 hours. Then, under the condition of ice bath, 200ml of water was slowly added into the flask, and 30% aqueous hydrogen peroxide was added into the flask until no more bubbles were generated. The obtained dispersion was centrifuged at 20,000 rpm for 1 hour. The resulting isolate was washed 3 times with deionized water to reach a pH of 7. Then vacuum dry at 50° C. for 12 h.

[0067] The preparation method of the carbon oxide nitride two-dimensional compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com