Preparation method of carbon nanotube/paraffin microcapsule with light absorption performance

A technology of paraffin microcapsules and carbon nanotubes, applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of heat storage and temperature control performance and application space limitations, and achieve improved heat storage and release Efficiency, improvement of emulsion stability, effect of increasing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of compound paraffin:

[0039]Weigh 16.2g of 46# solid paraffin and 37.8g of liquid paraffin in a 100ml beaker, stir in a water bath at 70°C for 30min, then weigh 6g of microcrystalline wax in the beaker, and continue stirring for 30min to obtain 60g of compound wax sample.

[0040] Hyperbranched multi-walled carbon nanotubes (WCNTs-HBP):

[0041] Accurately weigh 26.2856g (0.25mol) of ethylene glycol amine and 25ml of methanol in a 250ml three-necked flask equipped with a thermometer and a magnetic stirring device, and stir at room temperature. After the ethylene glycol amine is completely dissolved, slowly add 21.5230g (0.25mol) of methyl acrylate dropwise, raise the temperature to 40°C, stir with a constant temperature magnetic force for 4h, and then distill off the methanol under reduced pressure to obtain a colorless and transparent solution DEAM (N,N - Dihydroxyethyl-3-amine methyl acrylate). Then add 0.25g of p-toluenesulfonic acid and 0.25g of pen...

Embodiment 2

[0054] The mass ratio of the compounded paraffin, TAPP, WCNTs, OP-10 emulsifier and distilled water is 6:0.01:0.003:0.2:40.

[0055] The mass ratio of the hyperbranched multi-walled carbon nanotubes (WCNTs-HBP), distilled water, urea, melamine, and 37% formaldehyde solution is 0.01:50:1:2:10. Other steps are the same as in Example 1.

Embodiment 3

[0057] The mass ratio of the compounded paraffin, TAPP, WCNTs, OP-10 emulsifier and distilled water is 8:0.02:0.008:0.5:40.

[0058] The mass ratio of the hyperbranched multi-walled carbon nanotubes (WCNTs-HBP), distilled water, urea, melamine, and 37% formaldehyde solution is 0.02:50:3:5:15. Other steps are the same as in Example 1.

[0059] The microcapsules shown in Table 1 were prepared with the same experimental conditions and methods.

[0060] Results and discussion

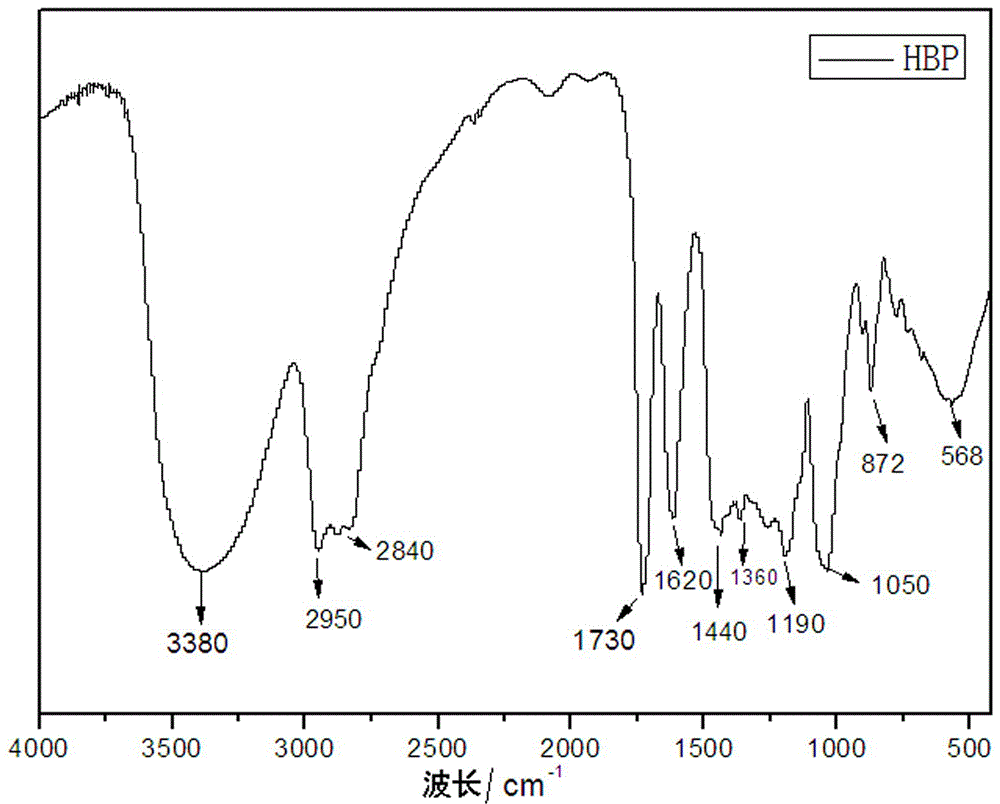

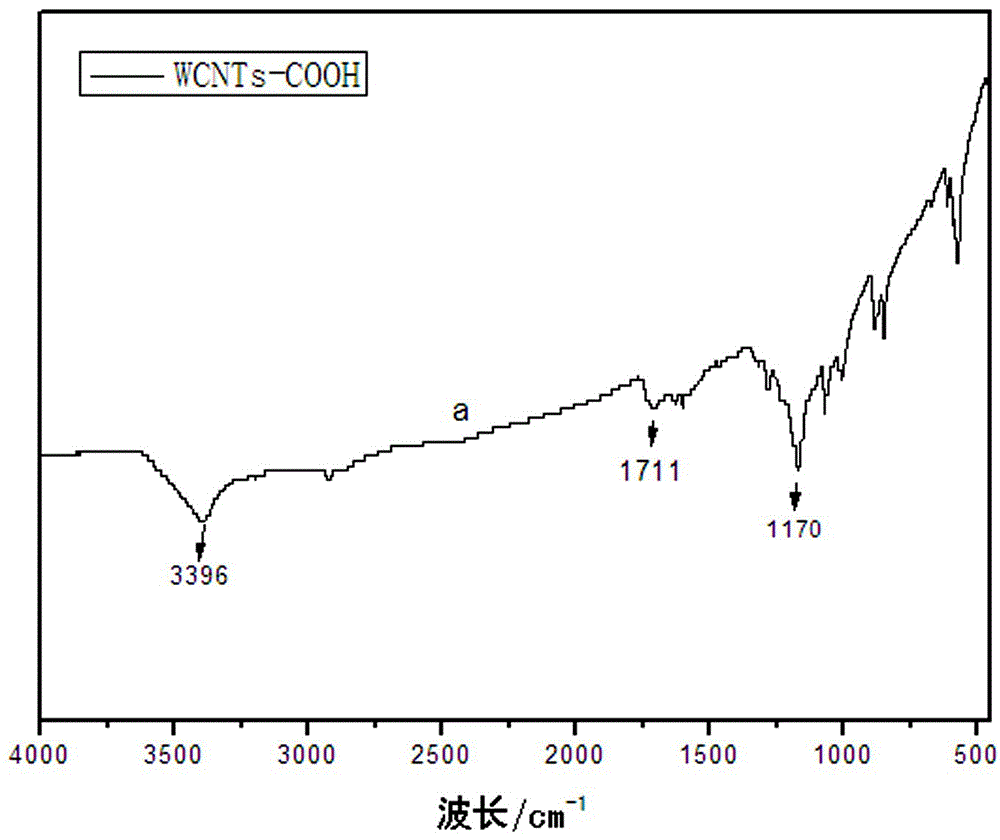

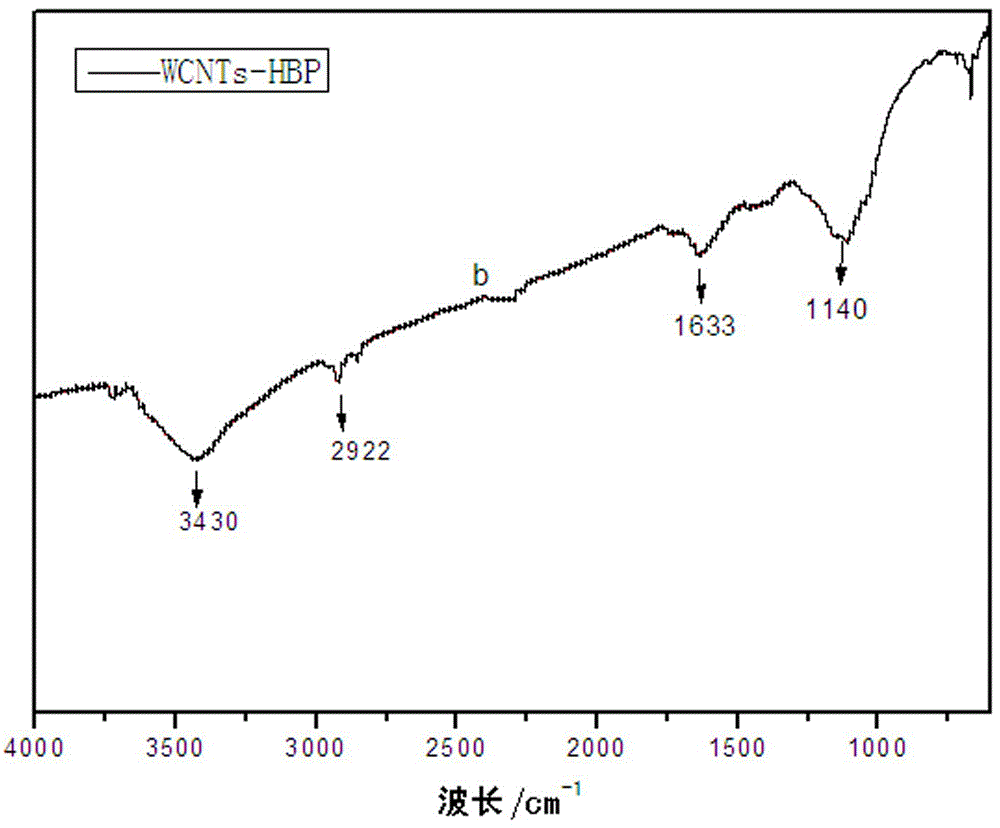

[0061] Structural characterization of carbon nanotubes and porphyrins: figure 1 It is the infrared detection spectrum of polyhydroxypolyurethane. 3380cm -1 The stretching vibration absorption peak of the O-H bond is at 2950cm -1 is the stretching vibration absorption peak of -CH3 and -CH2, 1730cm -1 It is the stretching vibration absorption peak of the C=O bond in the ester group, 1620cm -1 The place is -OH bending vibration absorption peak, 1440~1200cm -1 The bending vibration of C-H bond and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com