Preparation method of aluminum oxide film-layer carrier of integrated methane combustion catalyst

A methane combustion and aluminum oxide film technology, applied in the direction of catalyst carrier, combustion method, heterogeneous catalyst chemical elements, etc., can solve the problems of reduced content of perovskite active components, lower catalyst performance, and easy falling off of active components , to achieve the effects of simple process, favorable loading and dispersion, and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the aluminum oxide film layer carrier of the monolithic methane combustion catalyst described in this embodiment comprises the following steps:

[0038] (1) Pseudo-boehmite powder is weighed to form a slurry with a solid content of 10 wt%, and nitric acid is used to adjust the pH value of the slurry to 3.0 to obtain a stable aluminum sol;

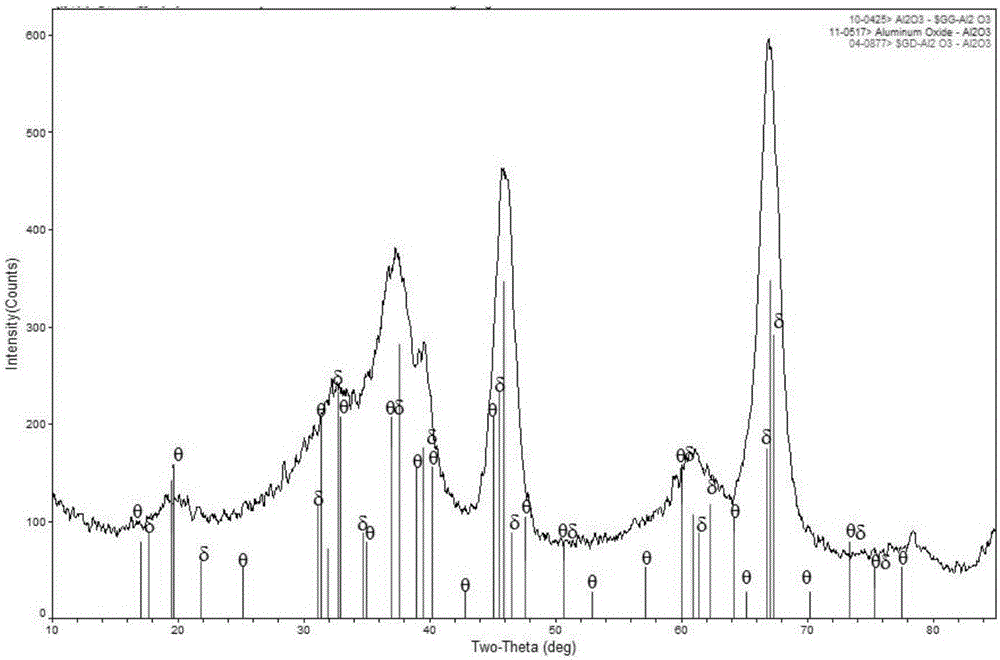

[0039] (2) Select a cordierite honeycomb carrier of 40-60 meshes, and dip the cordierite honeycomb carrier into the aluminum sol at a ratio of 0.3 mL of aluminum sol per gram of cordierite honeycomb carrier, and immerse it for about 3 minutes, repeat twice, and use Excessive aluminum sol was purged with high-pressure gas, dried at 120°C for 5 hours, placed in a muffle furnace, and fired at a temperature of 800°C for 3 hours. The aluminum oxide film layer was loaded on the cordierite honeycomb carrier, and detected by X-ray diffractometer. The crystal phase of the aluminum oxide film layer prepared in this em...

Embodiment 2

[0046] The preparation method of the aluminum oxide film layer carrier of the monolithic methane combustion catalyst described in this embodiment comprises the following steps:

[0047] (1) Pseudo-boehmite powder is weighed to make a slurry with a solid content of 5wt%, and nitric acid is used to adjust the pH value of the slurry to 3.0 to obtain a stable aluminum sol;

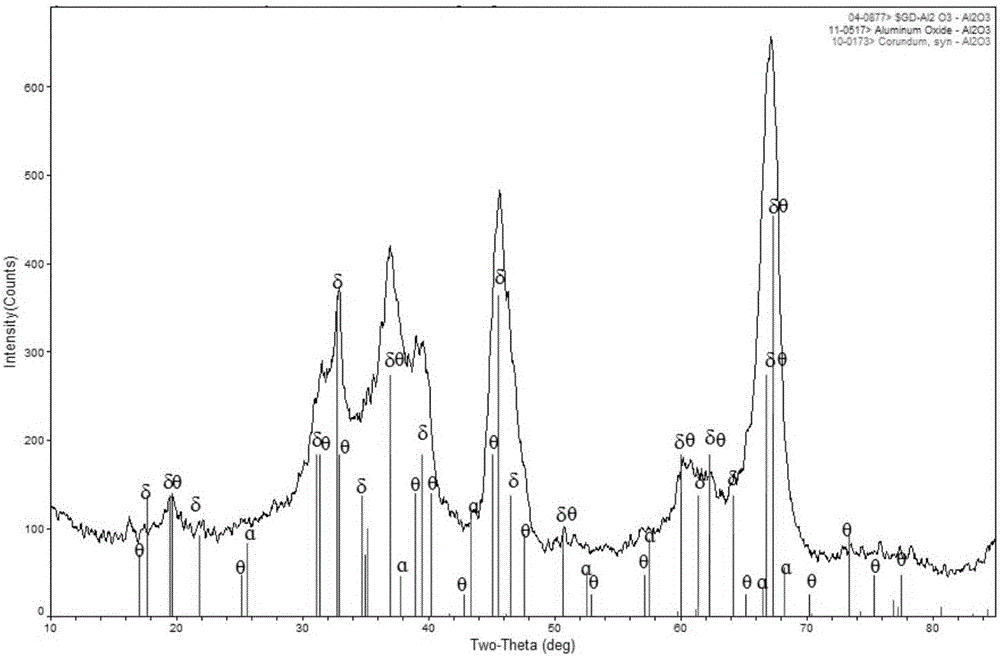

[0048] (2) Select a cordierite honeycomb carrier of 40-60 meshes, soak the cordierite honeycomb carrier in the ratio of 0.5mL aluminum sol per gram of cordierite honeycomb carrier, immerse the cordierite honeycomb carrier in the aluminum sol, dip for about 3min, repeat twice, use Excessive aluminum sol was purged with high-pressure gas, dried at 120°C for 4 hours, calcined at 1000°C for 3 hours, and loaded with an alumina film layer on the cordierite honeycomb carrier; detected by X-ray diffractometer, the oxide prepared in this example The crystal phase of the aluminum film layer has δ-phase, θ-phase and α-ph...

Embodiment 3

[0055] The preparation method of the aluminum oxide film layer carrier of the monolithic methane combustion catalyst described in this embodiment comprises the following steps:

[0056] (1) Pseudo-boehmite powder is weighed to make a slurry with a solid content of 10 wt%, and the pH value of the slurry is adjusted to 3.2 with nitric acid to obtain a stable aluminum sol;

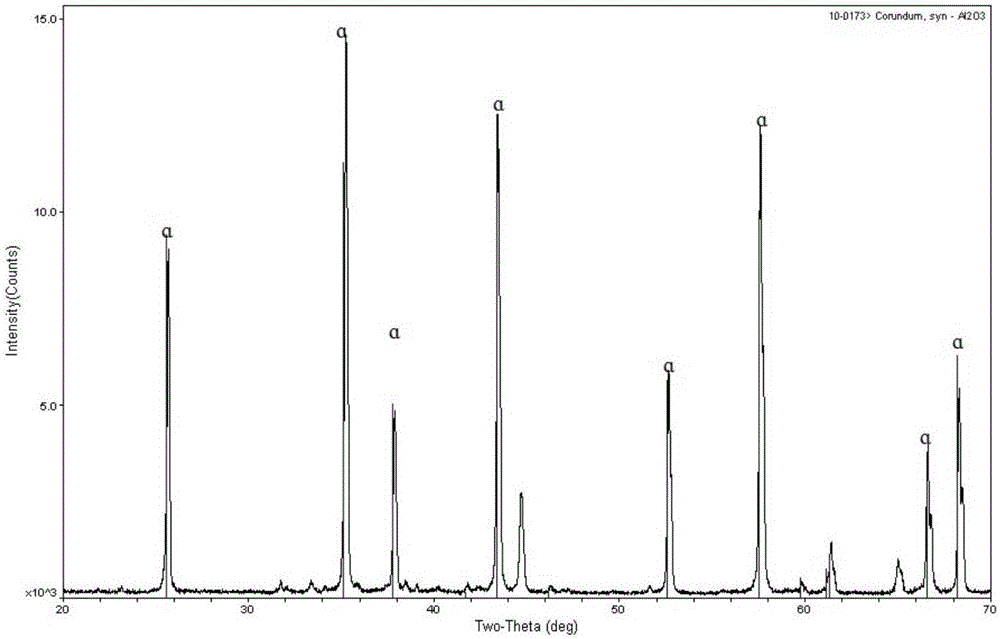

[0057] (2) Select a cordierite honeycomb carrier of 40-60 meshes, and soak the cordierite honeycomb carrier in the ratio of 0.4 mL of aluminum sol per gram of cordierite honeycomb carrier, and immerse the cordierite honeycomb carrier in the aluminum sol for about 3 minutes, repeat twice, and use Excessive aluminum sol is purged with high-pressure gas, dried at 120°C for 3 hours, placed in a muffle furnace, and fired at a temperature of 1200°C for 2 hours, and an alumina film layer is loaded on a cordierite honeycomb carrier, and detected by an X-ray diffractometer , the crystal phase of the aluminum oxide fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com