Preparation method of modified titanium dioxide powder and modified titanium dioxide powder

A titanium dioxide and powder technology, applied in titanium oxide/hydroxide, titanium dioxide, botanical equipment and methods, etc., can solve the problems of inability to realize industrialized production, low cost of chemical methods, and narrow application range, and achieve extended spectral response. The effect of interval, high yield and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

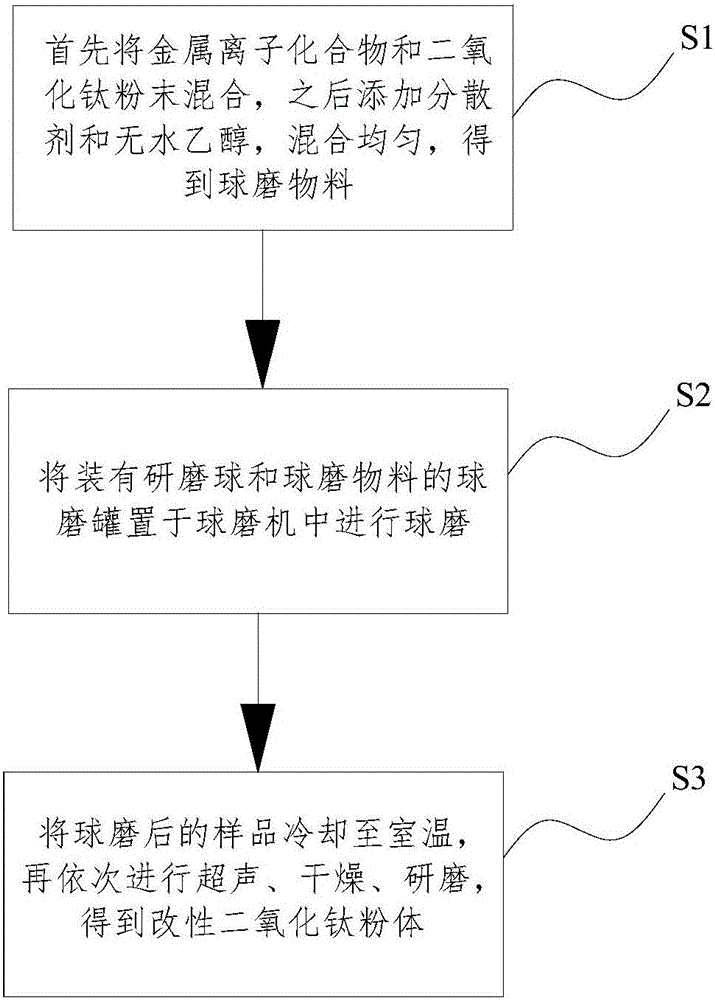

[0086] Embodiment 1 provides a kind of preparation method of modified titanium dioxide powder, comprises the following steps:

[0087] S1. Mix cobalt acetate and titanium dioxide powder with a molar ratio of 1:1 and a total mass of 100g, and add 2g of stearic acid and 50g of absolute ethanol (99.7% concentration) in sequence, mix and stir evenly to obtain ball milled materials ;

[0088] S21. Take zirconia grinding balls with a mass ratio of 2:2:1:1 and particle diameters of 3mm, 5mm, 8mm, and 10mm respectively, and place them in a 500ml alumina ball mill jar in descending order of size;

[0089] S22, spread the ball-milling material with a ball-to-material ratio of 10:1 on the grinding balls, put the ball milling jar with the grinding balls and the ball milling material together with the ball milling jar with the same quality of fine sand into the planetary high-energy ball mill for ball milling, Among them, the revolution speed of the ball mill is 300r / min, the revolution a...

Embodiment 2-5

[0092] Similar to the steps in Example 1, Example 2-5 is realized only by adjusting the ball milling time in step S22, and the other conditions remain unchanged. Specifically, the ball milling times in Examples 2, 3, 4, and 5 were 1 h, 3 h, 5 h, and 10 h, respectively.

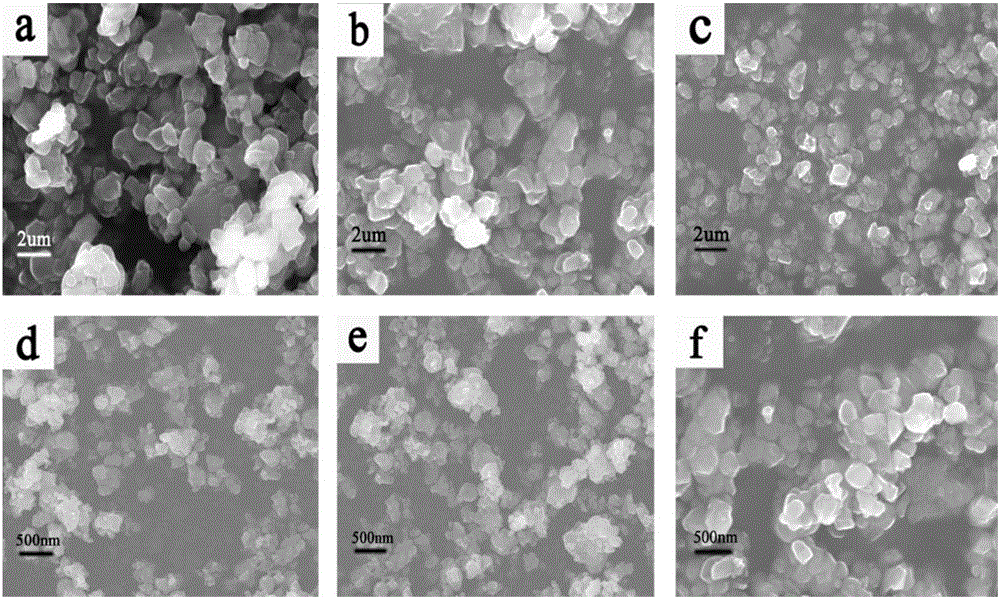

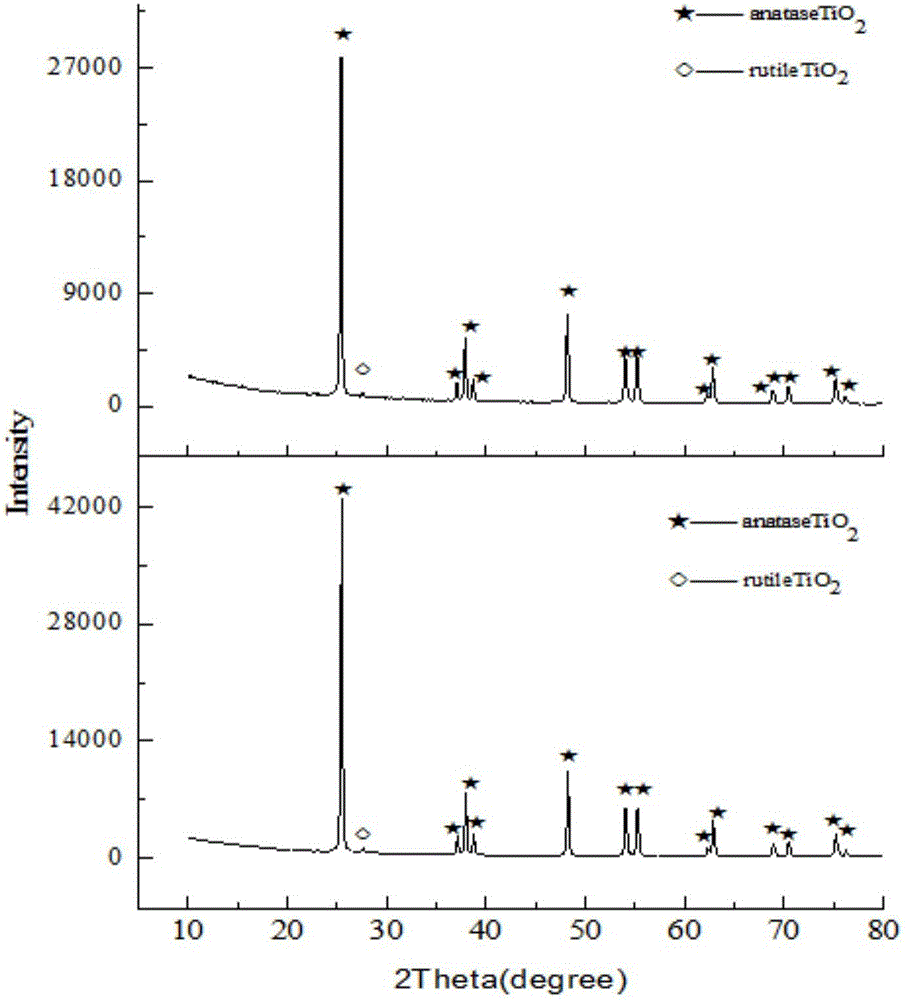

[0093] In conjunction with Examples 1-5, SEM, XRD, BET, UV-Vis-DRS and other tests were carried out on the modified titanium dioxide powder prepared in Examples 1-5. The test results are as follows: Figure 6-9 shown. The modified titanium dioxide powder prepared by the ball milling process in Examples 1-5 was used to test the antibacterial performance of Escherichia coli, and the test results are shown below.

[0094] combine Figure 6 to Figure 9 , the specific analysis is as follows: Figure 6 a-e show the particle size distribution of cobalt acetate-doped titanium dioxide powder after high-energy ball milling for 0.5-10 h. From Figure 6It can be seen that with the increase of ball milling time, the p...

Embodiment 6

[0100] Embodiment 6 provides a kind of preparation method of modified titanium dioxide powder, comprises the following steps:

[0101] S1. Mix cobalt acetate and titanium dioxide powder with a molar ratio of 1:10 and a total mass of 100g, and add 2g of stearic acid and 50g of absolute ethanol (concentration: 99.7%) in turn, mix and stir evenly to obtain ball milled materials ;

[0102] S21. Take zirconia grinding balls with a mass ratio of 2:2:1:1 and particle diameters of 3mm, 5mm, 8mm, and 10mm respectively, and place them in a 500ml alumina ball mill jar in descending order of size;

[0103] S22, spread the ball-milling material with a ball-to-material ratio of 10:1 on the grinding balls, put the ball milling jar with the grinding balls and the ball milling material together with the ball milling jar with the same quality of fine sand into the planetary high-energy ball mill for ball milling, Among them, the revolution speed of the ball mill is 300r / min, the revolution and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com