Preparation method of 1T-phase molybdenum disulfide

A molybdenum disulfide, molybdenum source technology, applied in the direction of molybdenum sulfide and other directions, can solve the problem of inability to prepare 1T phase molybdenum disulfide by one-pot reaction, and achieve the effects of high production efficiency and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

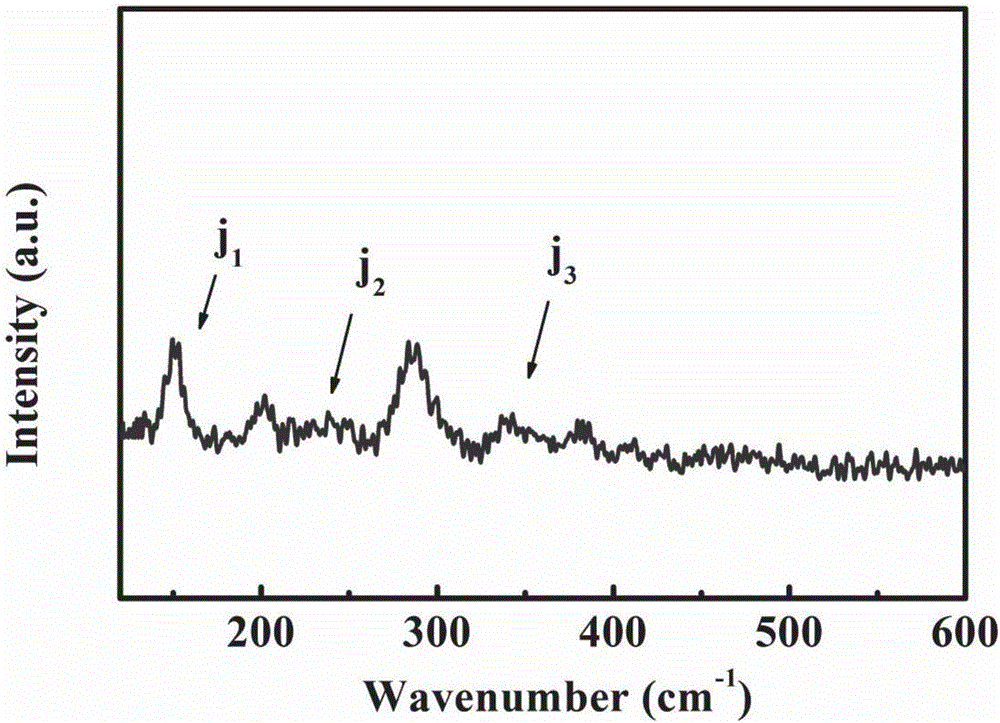

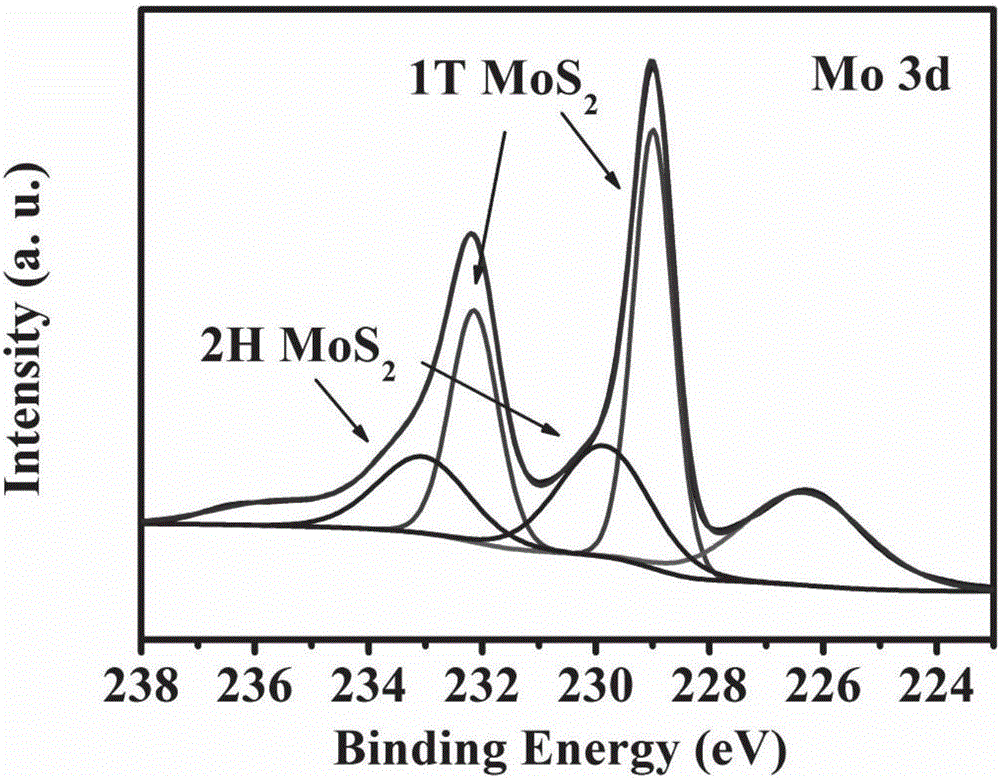

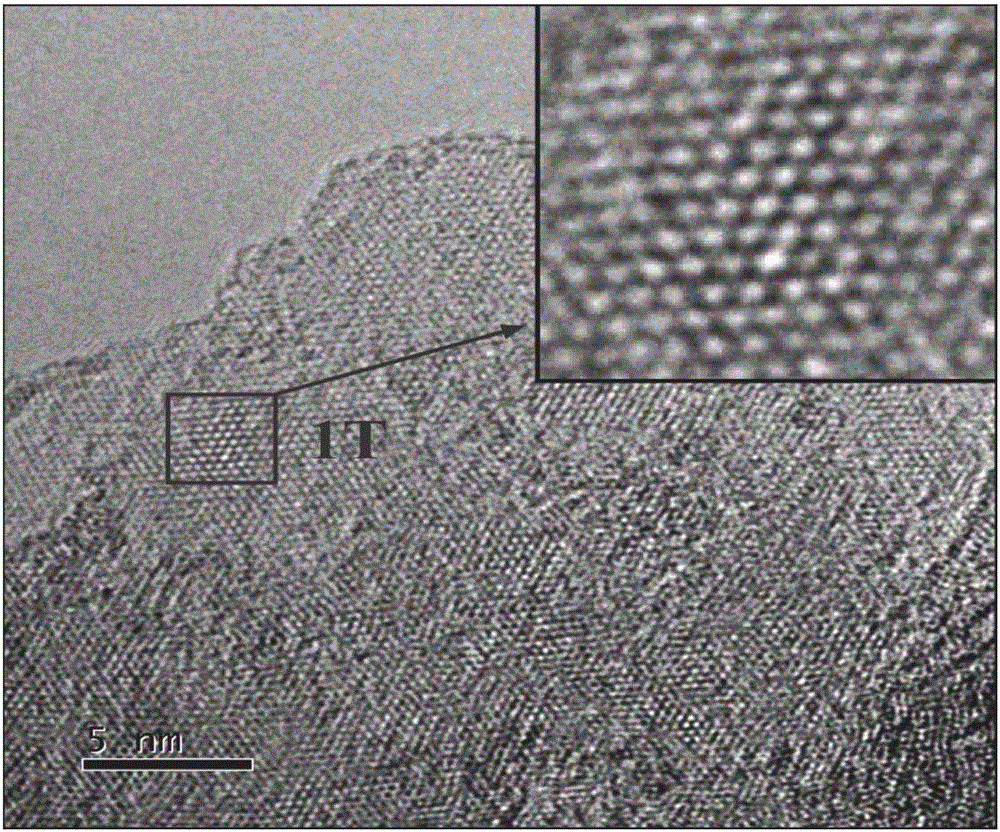

[0044] Place 0.88g ammonium molybdate, 0.94g thioacetamide and 1.98g ammonium bicarbonate in 40ml distilled water, stir with a magnetic stirrer for 30 minutes until the solution is colorless and transparent, pour it into the reactor and seal it, then Heat to 200°C and keep it warm for 13 hours. After cooling to room temperature, wash the product with distilled water and absolute ethanol, and dry it in a constant temperature drying oven at 60°C for 12 hours to obtain a black powder product. like figure 1 , the existence of 1T molybdenum disulfide can be preliminarily obtained through Raman spectroscopy, where the j 1 , j 2 and j 3 The characteristic peak represents the 1T phase molybdenum disulfide. pass figure 2 , XPS analysis further confirmed the presence of 1T phase molybdenum disulfide in the obtained molybdenum disulfide, and the proportion of 1T phase was greater than that of 2H phase. like image 3 , the existence of 1T phase molybdenum disulfide can be directly ...

Embodiment 2

[0046] Place 0.88g ammonium molybdate, 0.94g thioacetamide and 1.98g ammonium bicarbonate in 40ml distilled water, stir with a magnetic stirrer for 30 minutes until the solution is colorless and transparent, pour it into the reactor and seal it, then Heat to 180°C and keep it warm for 13 hours. After it is cooled to room temperature, wash the product with distilled water and absolute ethanol, and dry it in a constant temperature drying oven at 60°C for 12 hours to obtain 1T phase molybdenum disulfide. Among the hydrothermal products, the 1T phase product content is 53.7%.

Embodiment 3

[0048] Place 0.88g ammonium molybdate, 0.94g thioacetamide and 1.98g ammonium bicarbonate in 40ml distilled water, stir with a magnetic stirrer for 30 minutes until the solution is colorless and transparent, pour it into the reactor and seal it, then Heat to 160°C and keep it warm for 13 hours. After cooling to room temperature, wash the product with distilled water and absolute ethanol, and dry it in a constant temperature drying oven at 60°C for 12 hours to obtain 1T phase molybdenum disulfide. In the hydrothermal product, the 1T phase product content is 50.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com