Preparation methods of iron-sulfur compound and preparation method of iron-sulfur compound composite material

A technology of iron-sulfur compounds and composite materials, applied in the direction of iron sulfide, nanotechnology for materials and surface science, electrochemical generators, etc., can solve the problem of harmful L-cysteine inhalation into the respiratory tract, poor vulcanization effect, etc. problems, to achieve the effect of excellent electrochemical performance, uniform morphology, and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method for an iron-sulfur compound, comprising the steps of:

[0020] 1) Preparation of precursor A; the precursor A is iron oxide α-FeOOH or F-MIL, F=Fe; MIL=Materials from the Lavoisier Institute;

[0021] 2) Weigh the precursor A and sulfur powder respectively and place them in a porcelain boat, wherein the mass ratio of precursor A to sulfur powder is between 1:20-1:30 (1:20, 1:22, 1:24 can be selected , 1:26, 1:28, 1:30); put the porcelain boat in the annealing furnace, annealing reaction in the protective gas, the heating rate is between 1°C / min-3°C / min, precursor A and sulfur The way to put the powder in the porcelain boat is to mix it evenly or place it separately on both sides of the porcelain boat. ), the constant temperature time is between 1h-2h (1.0h, 1.2h, 1.4h, 1.6h, 1.8h, 2.0h), and the obtained product is iron-sulfur compound.

[0022] A preparation method of an iron-sulfur compound composite material, comprising the steps of:

[0023] ...

Embodiment 1

[0029] 1) Preparation of α-FeOOH;

[0030] 2) α-FeOOH@C is obtained by wrapping α-FeOOH with carbon;

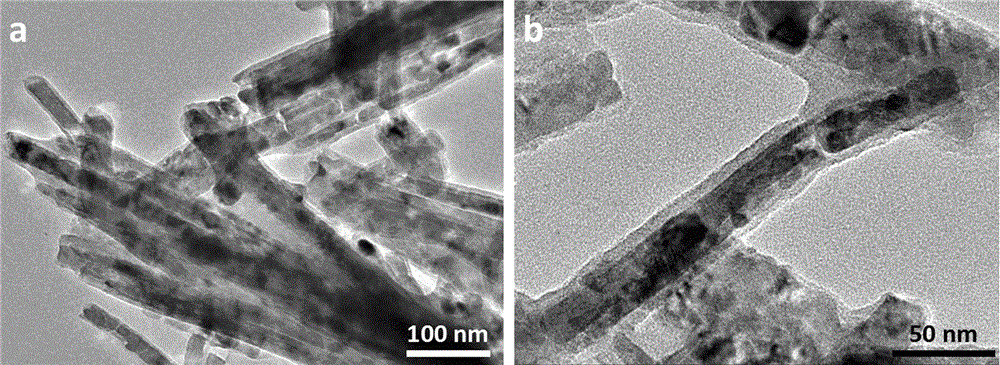

[0031] 3) Weigh 0.0500gα-FeOOH@C and 1g sulfur powder respectively, mix them evenly and place them on both sides of the porcelain boat respectively, place the porcelain boat in the annealing furnace, and raise the temperature at 2°C / min to 500°C, keep warm for 2h, cool down at 10°C / min, and collect the product, which is FeS 2 Nano stave. TEM transmission electron microscope photos are attached figure 1As shown, the shape of the nanorod is uniform, the diameter is about 15-20nm, and the size is about 400nm.

Embodiment 2

[0033] 1) Preparation of α-FeOOH;

[0034] 2) α-FeOOH@C is obtained by wrapping α-FeOOH with carbon;

[0035] 3) Weigh 0.0500g of α-FeOOH@C and 1g of sulfur powder respectively, mix them evenly and place them in a porcelain boat, place the porcelain boat in an annealing furnace, and heat up to 500°C at 2°C / min in an argon atmosphere. Keep warm for 12h, cool down at 10°C / min, and collect the product, which is FeS 2 @C nanorods.

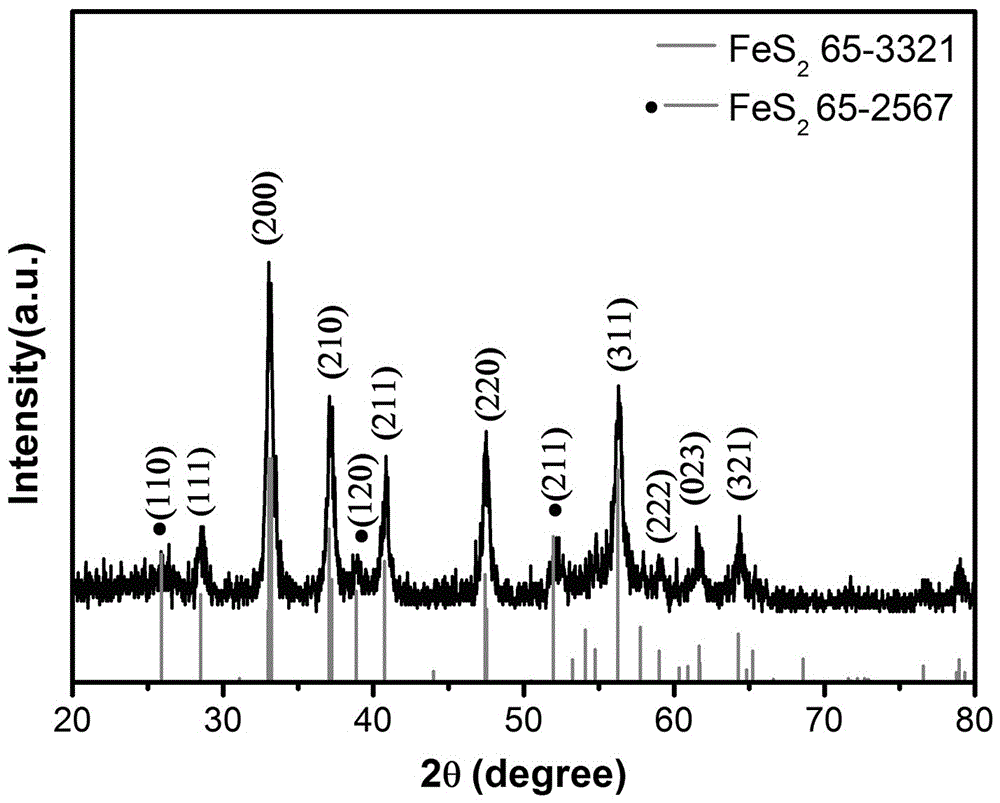

[0036] The XRD diffraction pattern of the ferrous disulfide in the present embodiment is as attached figure 2 shown. The ferrous disulfide nanorod in the present embodiment is carried out the electrochemical test of sodium ion battery:

[0037] 1) Mix and grind the prepared ferrous sulfide nanorods with acetylene black and carboxymethyl cellulose (CMC) in a mass ratio of 7:2:1 with deionized water as a solvent;

[0038] 2) Evenly coat the slurry obtained by grinding on the copper foil, after vacuum drying, punch holes into electrode sheets of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com