Return-flow type iron-carbon micro-electrolysis-coupling Fenton water treatment reaction device

An iron-carbon micro-electrolysis and reaction device technology, which is applied in the fields of reflux water treatment, special compound water treatment, water/sewage treatment, etc. , to achieve complete degradation of pollutants, facilitate industrial production, and prevent easy hardening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

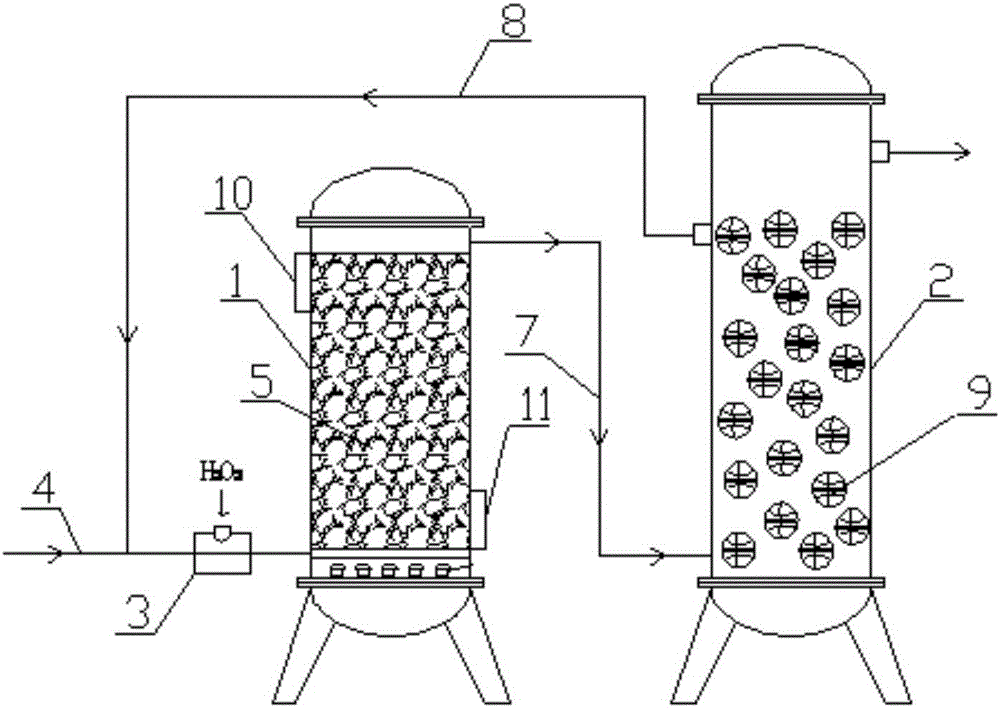

[0024] Such as figure 1 Shown, a kind of reflux type iron-carbon micro-electrolysis-coupling Fenton water treatment reaction device comprises iron-carbon micro-electrolysis-coupling Fenton reactor 1 and reflux tank 2 and dosing pipeline mixer 3 to form, it is characterized in that: in iron-carbon Micro-electrolysis-coupling-Fenton reactor 1 is equipped with a water inlet pipe 4 at the lower part of one side, and an iron-carbon tank outlet pipe 7 is installed at the upper part of the other side, and the iron-carbon micro-electrolysis-coupling Fenton reactor 1 and the reflux tank 2 pass through the iron-carbon water outlet Pipeline 7 links to each other, has dosing pipeline mixer 3 between water inlet pipeline 4 and iron-carbon micro-electrolysis-coupling Fenton reactor 1, and sewage enters dosing pipeline mixer 3 and H 2 o 2 After fully mixing, it enters the iron-carbon micro-electrolysis-coupling Fenton reactor 1, and then enters the return tank 2 through the iron-carbon tank...

Embodiment 2

[0032] Take pharmaceutical wastewater as an example: this kind of wastewater mainly comes from the production wastewater of a domestic pharmaceutical factory, and its main components are methylene chloride, xylene, isopropanol, methanesulfonic acid, tetrahydrofuran, toluene, acetone, etc.

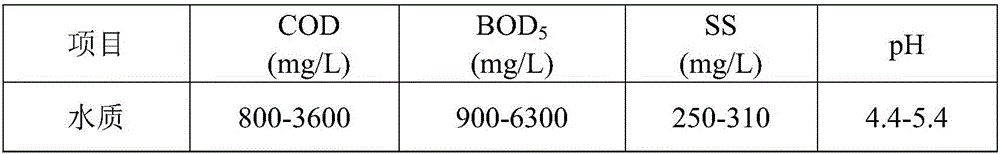

[0033] Table 1 Sewage Water Quality

[0034]

[0035] The operation results show that: the B / C value of the raw wastewater has increased from about 0.16 to about 0.45, which improves the biodegradability of the wastewater, and the COD removal rate is about 45%. It can be seen that the present invention has a better treatment effect on pharmaceutical wastewater, and the quality of pretreated effluent can meet the requirements of subsequent biochemical treatment.

Embodiment 3

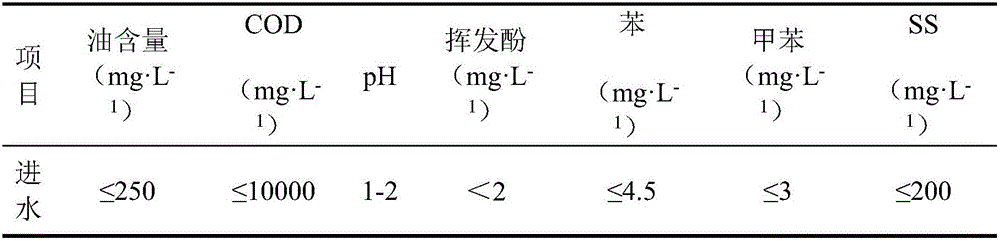

[0037] Take chemical wastewater as an example: this kind of wastewater mainly comes from a chemical production workshop, mainly for the production of thiophenol series of pharmaceutical intermediates. In the design, this experimental device is used as a pretreatment method, and it is also equipped with biochemical treatment. The quality of the wastewater is shown in Table 2.

[0038] Table 2 Chemical wastewater quality

[0039]

[0040] The running results show that the pH of the wastewater is effectively increased by this experimental device, and the amount of alkali required for the subsequent neutralization reaction is reduced; at the same time, the macromolecules and heterocyclic refractory organics in the wastewater are completely decomposed into more biodegradable organic compounds. Good alcohols, alcohols, shuttle acids and other small molecules can effectively improve the B / C ratio of wastewater. The total outlet oil content, COD, volatile phenol, benzene, toluene, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com