Metro engineering concrete containing microbial capsules and capable of realizing continuous self-repairing

A technology of microorganisms and concrete, applied in the direction of being fixed on or in an inorganic carrier, or being fixed on or in an organic carrier, etc., can solve the problems of poor adhesion, influence of strength, easy to be washed away, etc. The effect of strong performance, large adsorption capacity and good compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

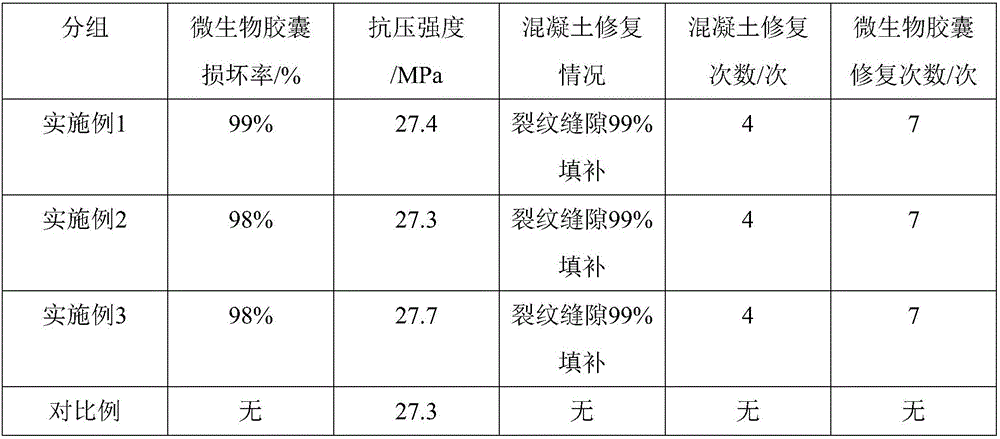

Examples

Embodiment 1

[0027] Preparation of microbial capsule:

[0028] Step 1. Cultivate Bacillus lysine and get the sludge after centrifugation. The sludge concentration is 6×10 9 Pcs / ml;

[0029] Step 2. Prepare anhydrous Bacillus lysine, tryptone 510g, soy peptone 90g, glucose 75, NaCl150g; dipotassium hydrogen phosphate 25g;

[0030] Step 3: Add all the culture medium and 0.1ml of bacterial mud configured in step 2 to 1200ml of water and stir to obtain a mixed solution;

[0031] Step 4. After adding 100 g of macroporous adsorption resin to the mixture obtained in step 3, stir at 250r / min for 30 minutes, filter and collect the macroporous adsorption resin, and bake at 20°C until the water content is less than 5%;

[0032] Step 5. Put the dried macroporous adsorption resin in 90% wt alcohol for the first soak for 30 minutes, and spray the cement liquid with a mass fraction of 20% on the surface uniformly to make the thickness 0.3mm Dry at ℃, spray again a mixture of cement and calcium chloride in a mass ...

Embodiment 2

[0036] Preparation of microbial capsule:

[0037] Step 1. Cultivate Bacillus lysine or Bacillus cereus, and obtain bacterial sludge after centrifugation, with a concentration of 6×10 9 Pcs / ml;

[0038] Step 2. Prepare anhydrous aerobic alkalophilic Bacillus culture medium, tryptone 510g, soy peptone 90g, glucose 75, NaCl150g; dipotassium hydrogen phosphate 25g;

[0039] Step 3: Add all the medium and 0.1ml of bacteria mud configured in Step 2 to 1500ml of water and stir to obtain a mixed solution;

[0040] Step 4. After adding 100 g of macroporous adsorption resin to the mixture obtained in step 3, stir at 250r / min for 20 minutes, filter and collect the macroporous adsorption resin, and bake at 30°C until the water content is less than 5%;

[0041] Step 5. Put the dried macroporous adsorption resin in 100% wt alcohol and soak it for 50 minutes once, and spray 25% cement liquid evenly on the surface to make the thickness 0.8mm and dry at 25°C , Spray the mixture of cement and calcium ch...

Embodiment 3

[0044] Preparation of microbial capsule:

[0045] Step 1. Cultivate Bacillus cereus, and get the sludge after centrifugation. The sludge concentration is 4×10 9 Pcs / ml;

[0046] Step two, configure anhydrous M.S.P medium, NaNO 3 9g, K 2 HPO 4 3g, KCI1.5g, MgSO 4 1.5g, FeSO 4 , 0.03g, 90g of sucrose;

[0047] Step 3: Add all the culture medium and 0.1ml of bacterial mud configured in step 2 to 180ml of water and stir to obtain a mixed solution;

[0048] Step 4. After adding 15 g of macroporous adsorption resin to the mixture obtained in step 3, stir for 30 min at a speed of 250r / min, filter and collect the macroporous adsorption resin, and bake at 30°C until the water content is less than 5%;

[0049] Step 5. Put the dried macroporous adsorption resin into 100%wt alcohol and soak it for 40min once, and spray 25% cement liquid evenly on the surface to make the thickness 0.5mm, and dry it at 30℃ Dry in a box, spray again a mixture of cement and calcium chloride with a mass ratio of 2:1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com