Method for producing liquid fertilizer by bamboo shoot wastewater

A technology for wastewater and bamboo shoots, applied in the preparation of liquid fertilizers, organic fertilizers, sewage/sludge fertilizers, etc., can solve the problems of building a large number of treatment facilities, high treatment costs, complicated treatment processes, etc. The effect of pests and diseases, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

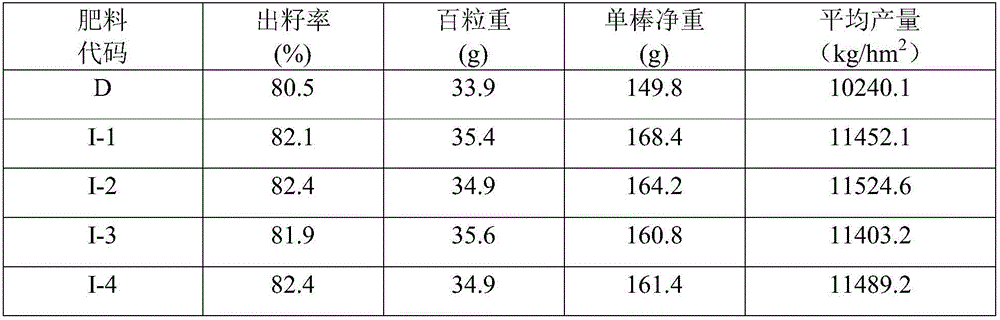

Examples

Embodiment 1

[0023] The method for producing liquid fertilizer from bamboo shoot wastewater of the present invention, its raw material comprises 50 parts of fresh bamboo shoot wastewater, 10 parts of urea ammonium nitrate solution, 10 parts of ammonium polyphosphate solution, 5 parts of potassium sulfate and potassium chloride each, 5 parts of citric acid, sulfuric acid 0.5 parts of copper, ferrous chloride, zinc chloride, manganese sulfate, boric acid in total, the mass ratio is 2:1:1:1:0.5, 5 parts of botanical fungicide and 2 parts of glucitol;

[0024] The bamboo shoot wastewater is the wastewater produced by soaking bamboo shoots, simply cooking, packaging, and high-temperature sterilization, and then filtering the wastewater to remove bamboo shoot residues to obtain bamboo shoot wastewater;

[0025] The production process is as follows: according to the above formula, fresh bamboo shoot wastewater is weighed and put into a closed fermenter for fermentation, the fermentation temperatur...

Embodiment 2

[0028] The method for producing liquid fertilizer from bamboo shoot wastewater of the present invention, its raw material comprises 40 parts of fresh bamboo shoot wastewater, 5 parts of urea ammonium nitrate solution, 5 parts of ammonium polyphosphate solution, 5 parts of potassium sulfate and potassium chloride each, 5 parts of amino acid, copper sulfate , ferrous chloride, zinc chloride, manganese sulfate, and boric acid are 0.2 parts in total, with a mass ratio of 1:1:1:0.5:0.5, 2 parts of botanical pesticide extracts, and 1 part each of mannitol and lactitol;

[0029] The bamboo shoot wastewater is the wastewater produced by soaking bamboo shoots, simply cooking, packaging, and high-temperature sterilization, and then filtering the wastewater to remove bamboo shoot residues to obtain bamboo shoot wastewater;

[0030] The production process is as follows: according to the above formula, take fresh bamboo shoot waste water and put it into a closed fermenter for fermentation, ...

Embodiment 3

[0033] The method for producing liquid fertilizer from bamboo shoot waste water of the present invention, its raw material comprises 40 parts of fresh bamboo shoot waste water, 10 parts of urea ammonium nitrate solution, 10 parts of ammonium polyphosphate solution, 6 parts of potassium sulfate and potassium chloride each, 1 part of amino acid, yellow humus 1 part of acid, 1 part of citric acid, 1 part of tartaric acid, 0.4 parts of copper sulfate, ferrous chloride, zinc chloride, manganese sulfate, boric acid, the mass ratio range is 2:1:2:1:1, plant 3 parts of source pesticide extract and 2 parts of mannitol;

[0034] The bamboo shoot wastewater is the wastewater produced by soaking bamboo shoots, simply cooking, packaging, and high-temperature sterilization, and then filtering the wastewater to remove bamboo shoot residues to obtain bamboo shoot wastewater;

[0035] The production process is as follows: according to the above formula, fresh bamboo shoot waste water is weighe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com