Wheat tillering fertilizer as well as preparation method and application thereof

A tillering fertilizer and wheat technology, which is applied in the field of wheat tillering fertilizer and its preparation, can solve the problems of increased wheat ineffective tillering, decreased economic benefits, increased emptying rate, etc., to increase utilization rate and use effect, reduce soil bulk density, release-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The raw material component of the wheat tillering fertilizer that embodiment 1 provides is as follows:

[0041] Macroelement 600g: ammonium polyphosphate 92g, monoammonium phosphate 139g, potassium nitrate 185g, potassium sulfate 92g, urea 92g;

[0042] Trace elements 220g: zinc sulfate 55g, manganese sulfate 11g, amino acid zinc 154g;

[0043] Tiller-inducing factor 24g: 30% uniconazole 18g, potassium indolebutyrate 2g, sodium naphthalene acetate 4g;

[0044] Organic matter 135g: fulvic acid 110g, humic acid 25g;

[0045] Adhesive: polyacrylamide 4g, sodium alginate 2g.

Embodiment 2

[0047] The raw material component of the wheat tillering fertilizer that embodiment 2 provides is as follows:

[0048] Macroelement 650g: ammonium polyphosphate 100g, monoammonium phosphate 150g, potassium nitrate 200g, potassium sulfate 100g, urea 100g;

[0049] Trace elements 200g: zinc sulfate 50g, manganese sulfate 10g, amino acid zinc 140g;

[0050] Tiller-inducing factor 24g: 30% uniconazole 20g, potassium indolebutyrate 1g, sodium naphthalene acetate 3g;

[0051] Organic matter 120g: fulvic acid 100g, humic acid 20g;

[0052] Adhesive: polyacrylamide 1g, sodium alginate 3g, bentonite 2g.

Embodiment 3

[0054] The raw material component of the wheat tillering fertilizer that embodiment 3 provides is as follows:

[0055] Macroelement 680g: ammonium polyphosphate 105g, monoammonium phosphate 157g, potassium nitrate 209g, potassium sulfate 104g, urea 105g;

[0056] Trace elements 180g: zinc sulfate 45g, manganese sulfate 9g, amino acid zinc 126g;

[0057] Tiller-inducing factor 24g: 30% uniconazole 19g, potassium indolebutyrate 3g, sodium naphthalene acetate 2g;

[0058] Organic matter 110g: fulvic acid 92g, humic acid 18g;

[0059] Adhesive: polyacrylamide 3g, sodium alginate 2g, bentonite 1g.

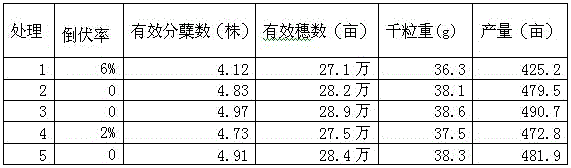

[0060] The use effect of the wheat tillering manure that embodiment 1-3 provides is described below:

[0061] 1. Test site and soil properties

[0062] Test location: Jingmen City, Hubei Province, 112°69′ east longitude, 31°02′ north latitude.

[0063] Experimental variety: Emai 251.

[0064] Nutrient conditions of the tested soil: pH5.2, total N1.82g / Kg, organic C19.1g / Kg, effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com