Fucoidan sulfate oligosaccharide and its preparation method and application

A technology of fucoidan sulfate and fucoidan sulfate, which is applied in the field of fucoidan sulfate oligosaccharides and its preparation and application, can solve the problem of small application range, limited number of fucose residues and Types and other issues, to achieve the effect of enriching types, expanding the scope of use, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

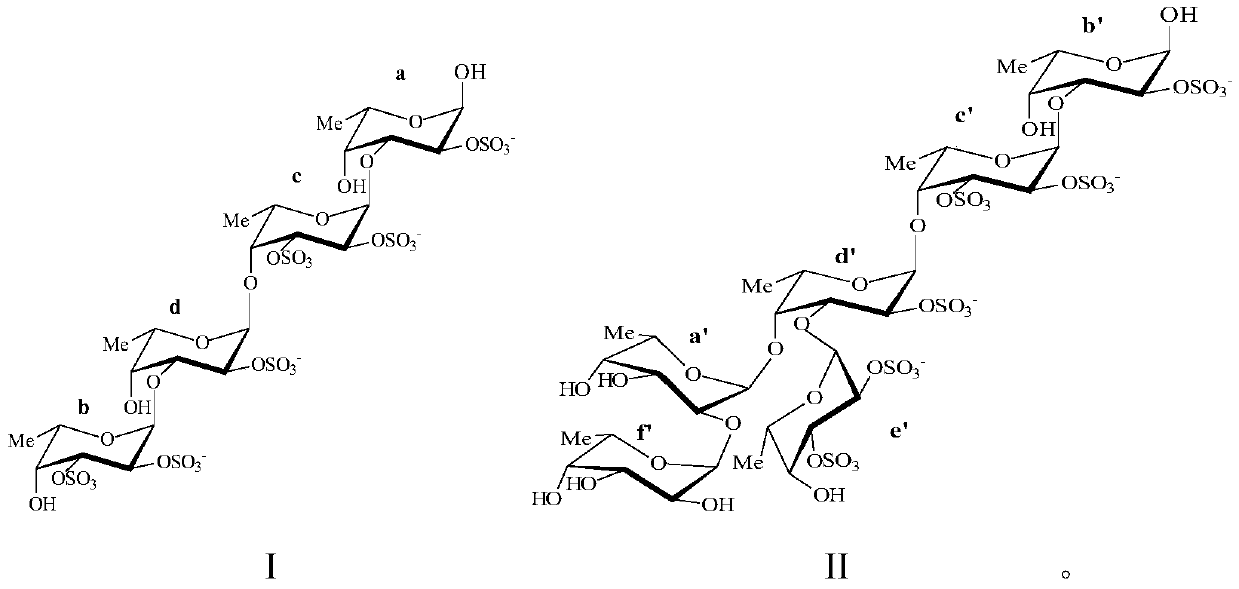

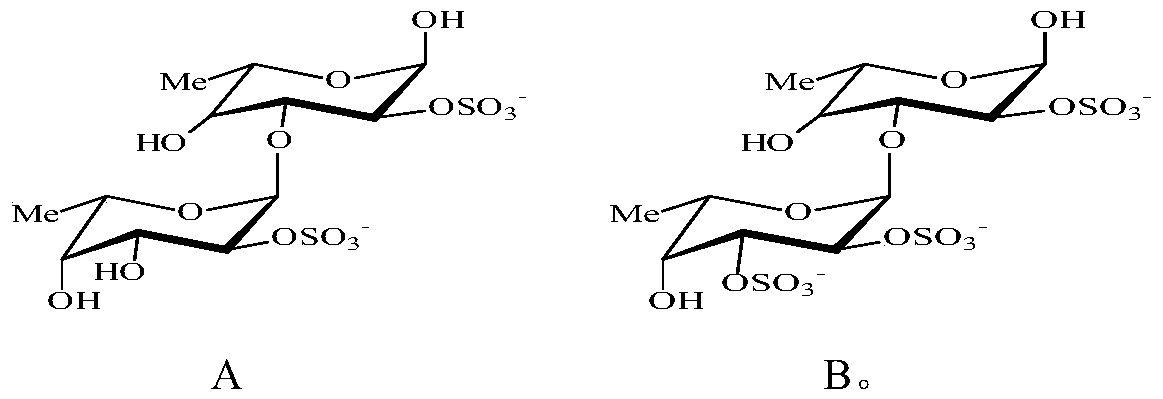

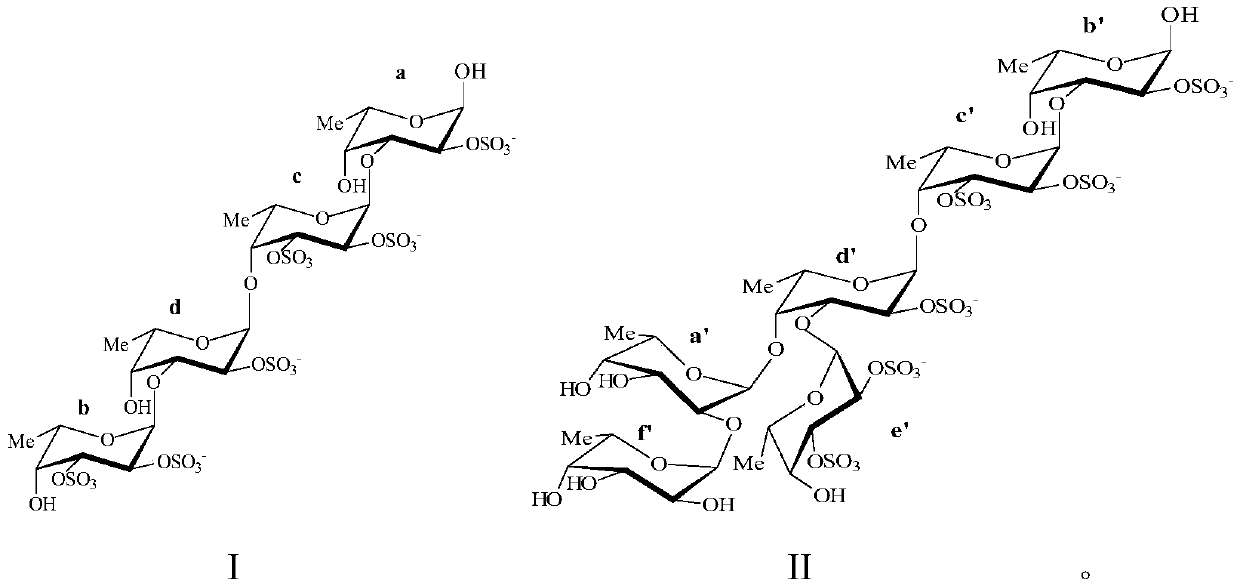

Embodiment 1

[0036] Put the recombinant fucoidanase FFA1 (1mg) into the Tris-HCl buffer solution with a pH value of 7.2, mix it with 5% copper algae (Sargassum horneri) fucoidan solution, and put the mixture at a temperature of 37°C Artificially cultivated for 72 hours, and then heated to 100°C for 5 minutes. The resulting precipitate was separated by centrifugation and discarded. Add ethanol to the supernatant until its concentration reaches 75%. The formed precipitate (polymer component) was centrifuged at 9000 g for 20 min. The supernatant (low molecular components) was poured into a column containing Q-Sepharose adsorbent, and equilibrated with pure water. The oligosaccharides were then eluted with a linear gradient of ammonium bicarbonate at a rate of 1 mL / min. First operate to obtain sulfated fucosylated oligosaccharides with molecular formula II, then operate to obtain sulfated fucosylated oligosaccharides with molecular formula I, and then freeze-dry the obtained product to obta...

Embodiment 2

[0038] Put the recombinant fucoidanase FFA1 (1mg) into the Tris-HCl buffer solution with a pH value of 7.2, mix it with 10% copper algae (Sargassum horneri) fucoidan solution, and put the mixture at a temperature of 37°C Artificially cultivated for 75 hours, and then heated to 100°C for 10 minutes. The resulting precipitate was separated by centrifugation and discarded. Add acetone to the supernatant until its concentration reaches 75%. The formed precipitate (macromolecule component) was centrifuged at 10000 g for 30 min. The supernatant (low molecular components) was poured into a column containing Q-Sepharose adsorbent, and equilibrated with pure water. Then, the oligosaccharides were eluted with a linear gradient of ammonium bicarbonate at a speed of 1 mL / min. First operate to obtain the fucoidan sulfate oligosaccharide with molecular formula II, then operate to obtain the fucoidan sulfate oligosaccharide with molecular formula I, then freeze-dry the obtained product, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com