Toxic ligand free electrochemistry regulated atom transfer radical polymerization method

A technology of atom transfer and polymerization method, which is applied in the field of electrochemically regulated atom transfer radical polymerization of non-toxic ligands, which can solve the problems of difficult storage and handling of low-valence transition metal catalysts, high price, etc., and simplify the post-processing process , reduce the cost of raw materials, optimize the effect of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] After purification of methyl methacrylate monomer, acetonitrile solvent, and ethyl 2-bromophenylacetate initiator, the polymerization reaction components are prepared, methyl methacrylate, ethyl 2-bromophenylacetate, iron bromide The molar ratio is 200:1:1, and the volume ratio of methyl methacrylate and acetonitrile is 1:1. The preparation process is: weigh 0.0836 grams of ferric bromide and 0.1303 grams of tetraethylammonium tetrafluoroborate in the glove box and put them into a four-necked bottle, take 6 milliliters of methyl methacrylate monomer and 6 milliliters of acetonitrile with a needle tube and add to In the four-neck flask, after 20 minutes of magnetic stirring, 49.5 microliters of ethyl 2-bromophenylacetate was added, and the stirring was continued for 2 minutes to obtain a pre-reaction mixture.

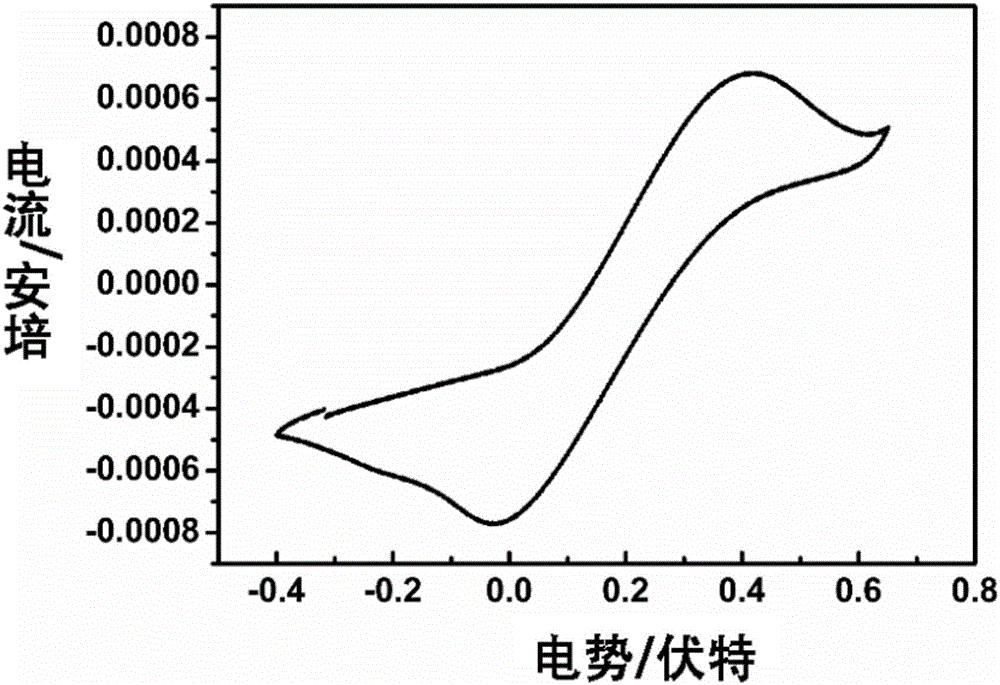

[0043] Transfer the pre-reaction mixture in the four-shaped bottle to the heating device, control the reaction temperature to 60°C; connect the electrode to set t...

Embodiment 2

[0045] After purifying n-butyl methacrylate monomer, acetonitrile and ethyl 2-bromophenylacetate initiator, the polymerization reaction components were prepared, n-butyl methacrylate, ethyl 2-bromophenylacetate, bromide The molar ratio of iron is 200:1:1, and the volume ratio of n-butyl methacrylate and acetonitrile is 1:1. The preparation process is as follows: weigh 0.0836 grams of ferric bromide and 0.1303 grams of tetraethylammonium tetrafluoroborate in the glove box and put them into a four-neck bottle, take 8 milliliters of n-butyl methacrylate monomer and 8 milliliters of acetonitrile and add into a four-neck flask, and after magnetically stirring for 20 minutes, add 49.5 microliters of ethyl 2-bromophenylacetate, and continue stirring for 2 minutes to obtain a pre-reaction mixture.

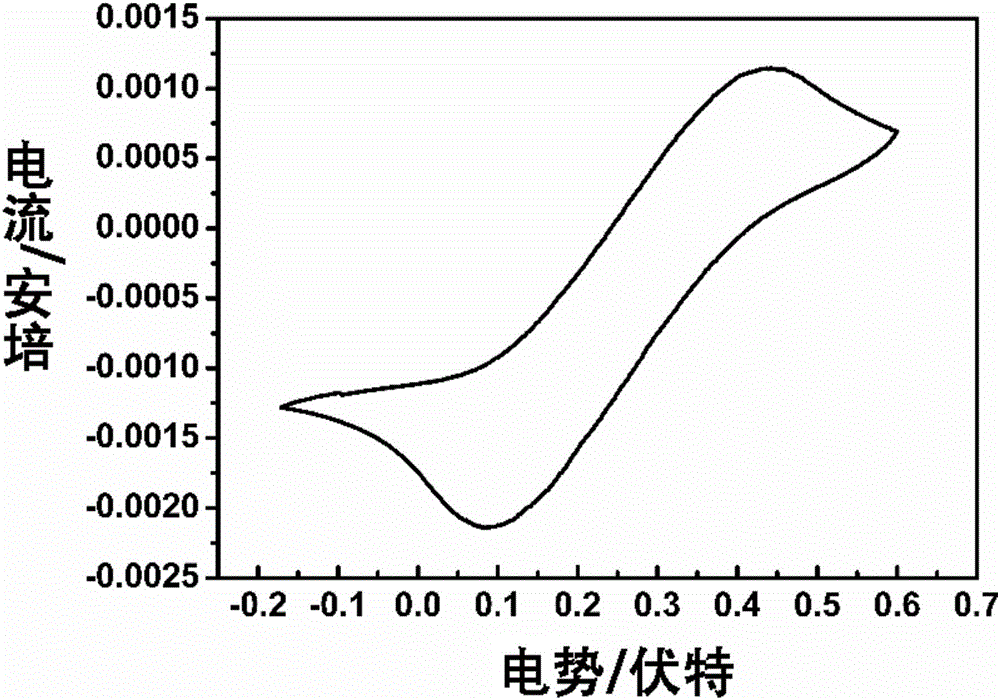

[0046] Transfer the pre-reaction mixture in the four-shaped bottle to the heating device, control the reaction temperature to 60°C; connect the electrode, set the voltage (voltage is -0.3V...

Embodiment 3

[0048] After purification of methyl acrylate monomer, N-methylpyrrolidone as solvent and ethyl 2-bromophenylacetate initiator, the polymerization reaction components are prepared, methyl acrylate, ethyl 2-bromophenylacetate, bromide The molar ratio of iron is 200:1:1, and the volume ratio of methyl acrylate and N-methylpyrrolidone is 1:1. The preparation process is as follows: weigh 0.0836 grams of ferric bromide and 0.1303 grams of tetraethylammonium tetrafluoroborate into a four-necked bottle in the glove box, and take 6 milliliters of methyl methacrylate monomer and 6 milliliters of N-methyl methacrylate monomer with a needle tube. The base pyrrolidone was added into the four-neck flask, and after magnetic stirring for 20 minutes, 49.5 microliters of ethyl 2-bromophenylacetate was added, and the stirring was continued for 2 minutes to obtain a pre-reaction mixture.

[0049] Transfer the pre-reaction mixture in the four-shaped bottle to the heating device, control the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com