A kind of preparation method of solid polycarboxylate water reducer

A technology of polycarboxylic acid and water-reducing agent, applied in the field of building admixtures, can solve the problems of insufficient green production process, loss of polycarboxylic acid water-reducing agent, expensive equipment and other problems, and achieve excellent water-reducing and dispersing effect and strong adaptability. performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

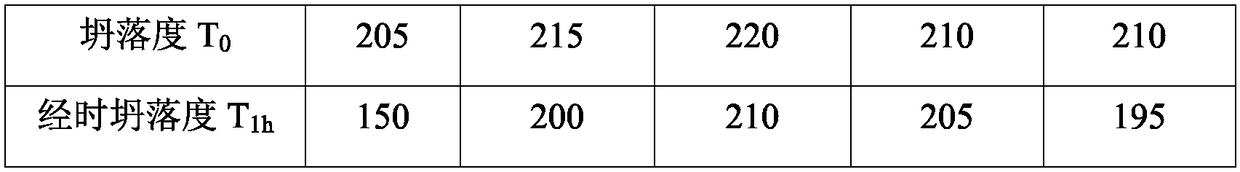

Examples

Embodiment 1

[0024] A preparation method of solid polycarboxylate water reducer, comprising the following steps:

[0025] (1) Add 3-methyl-3-butene-1-polyoxyethylene ether and sodium methallyl sulfonate into the reaction kettle, raise the temperature to 60°C to make it in a molten state, and then Add Mohr's salt and stir well;

[0026] (2) Add dropwise the first mixed solution composed of acrylic acid and azobisisobutyronitrile and the second mixed solution composed of di(hydroxyethyl acrylate) phosphate and mercaptoacetic acid respectively, drop after 2.5h, and the dropwise addition ends Afterwards, slaking for 1h, then adding solid sodium hydroxide for neutralization;

[0027] (3) Finally, the material obtained in step (2) is sliced by a condensing microtome to obtain the solid polycarboxylate superplasticizer in the form of white flakes. Wherein: 3-methyl-3-butene-1-polyoxyethylene ether: acrylic acid: di(hydroxyethyl acrylate) phosphate: the molar ratio of sodium methallyl sulfonat...

Embodiment 2

[0029] A preparation method of solid polycarboxylate water reducer, comprising the following steps:

[0030] (1) Add allyl polyoxyethylene ether and sodium styrene sulfonate to the reaction kettle, raise the temperature to 70°C, make it in a molten state, then add N,N-dimethylaniline at one time, and stir Uniform;

[0031] (2) Add dropwise the first mixed solution composed of methacrylic acid and cumene hydroperoxide and the second mixed solution composed of hydrogen phosphate di(methacryloyloxyethyl) ester and 3-mercaptopropionic acid , after 2 hours of dripping, after the dropwise addition, ripen for 1 hour, and then add solid sodium hydroxide for neutralization;

[0032] (3) Finally, the material obtained in step (2) is sliced by a condensing microtome to obtain the solid polycarboxylate superplasticizer in the form of white flakes. Among them: the molar ratio of allyl polyoxyethylene ether: methacrylic acid: bis(methacryloyloxyethyl) phosphate: sodium styrene sulfonate...

Embodiment 3

[0034] A preparation method of solid polycarboxylate water reducer, comprising the following steps:

[0035] (1) Add 2-methallyl polyoxyethylene ether and sodium 2-acrylamido-2-methylpropanesulfonate into the reaction kettle, raise the temperature to 80°C to make it in a molten state, and then once Add N, N-dimethylaniline, and stir evenly;

[0036] (2) Add dropwise the first mixed solution composed of maleic acid and tert-butyl peroxybenzoate and the second mixture composed of hydrogen phosphate di(methacryloyloxyethyl) ester and n-dodecylmercaptan. Mixed liquid, dripping after 3h, after the dropwise addition, aging for 1h, then adding solid sodium hydroxide for neutralization;

[0037] (3) Finally, the material obtained in step (2) is sliced by a condensing microtome to obtain the solid polycarboxylate superplasticizer in the form of white flakes. Among them: 2-methallyl polyoxyethylene ether: maleic acid: bis(methacryloyloxyethyl) hydrogen phosphate: molar ratio of 2-ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com