Super high-early-strength type polycarboxylate superplasticizer and preparation method thereof

A super early-strength, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problem of slow strength development, achieve the effects of stable strength growth in the middle and late stages, improve construction progress, and speed up formwork turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

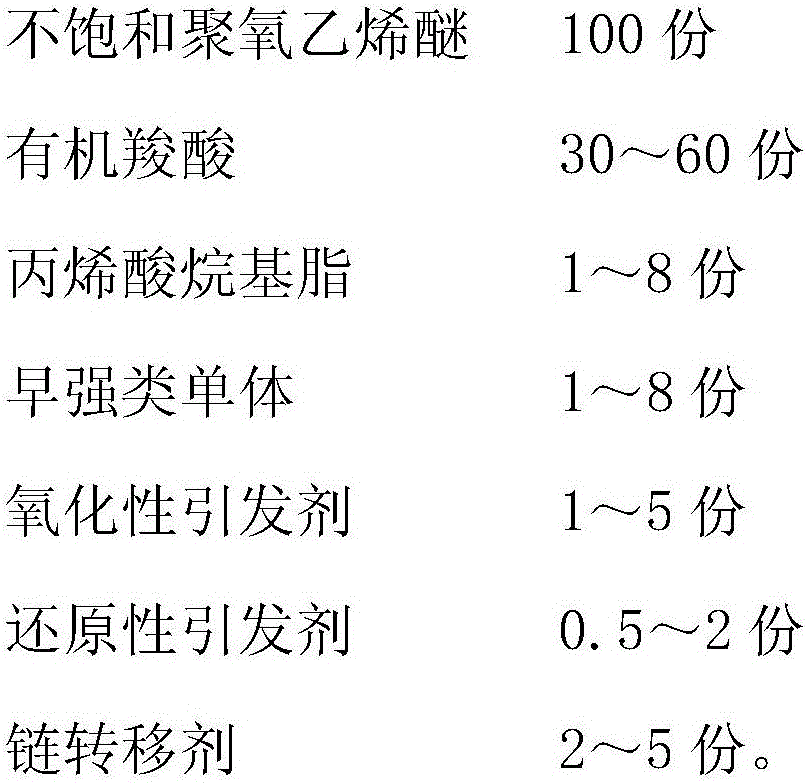

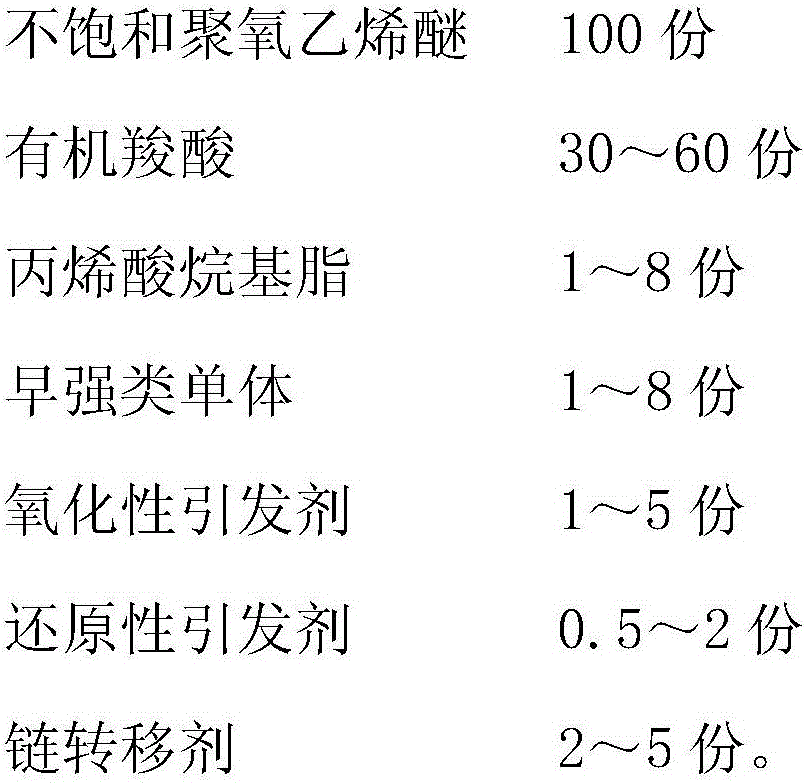

Method used

Image

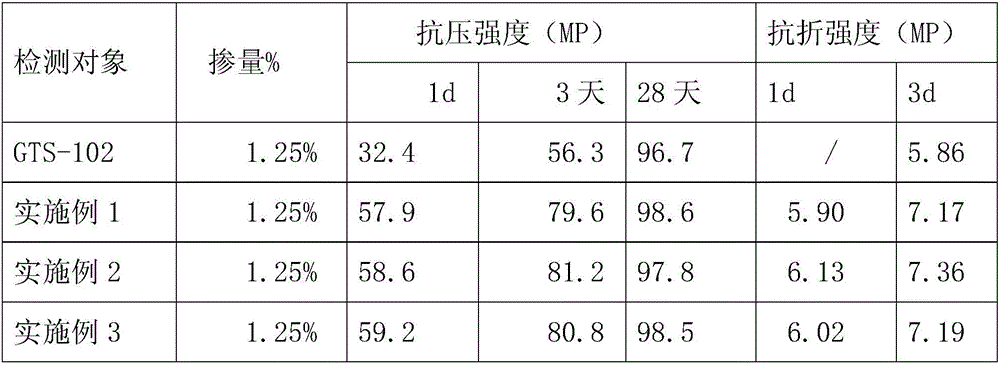

Examples

Embodiment 1

[0024] Add 210g of water, 200g of methacryl alcohol polyoxyethylene ether (HPEG3600), 3.0g of ethyl acrylate and 3.0g of hydrogen peroxide into a 1000ml round-bottomed three-necked flask as the reaction bottom liquid.

[0025] Prepare solution A: mix 32.0 g of acrylic acid, 2.0 g of acrylamide and 40 g of water and put them in the dropping funnel.

[0026] Preparation of solution B: mix 1.0 g vitamin C, 2.0 g mercaptopropionic acid and 60 g water and put them in the dropping funnel.

[0027] Stir until the monomers in the flask are dissolved, and raise the temperature to 70°C. Immediately start adding liquid A and liquid B dropwise at the same time. Solution A will be dropped in 3.0 hours at the same time, and solution B will be dropped in 3.5 hours. After continuing the heat preservation reaction for 0.5 hours, add 5.0 The ethanolamine is partially neutralized, the pH value of the solution is adjusted to 6-7 with a sodium hydroxide solution, and water is replenished to obtain...

Embodiment 2

[0029] Add 210g of water, 200g of methacryl alcohol polyoxyethylene ether (HPEG4000), 3.5g of butyl acrylate as the reaction bottom liquid, 2.0g of ammonium persulfate and 1.0g of hydrogen peroxide into a 1000ml round bottom three-neck flask.

[0030] Preparation of solution A: Mix 28g of acrylic acid, 3.0g of AMPS and 30g of water and put them in the dropping funnel.

[0031] Preparation of solution B: Mix 2.5 grams of mercaptopropionic acid, 1.0 grams of scallops and 60 g of water and put them in a dropping bottle.

[0032] Stir until the monomers in the flask are dissolved, and raise the temperature to 70°C. Immediately start adding liquid A and liquid B dropwise at the same time. Liquid A drops in 2.0 hours, and liquid A drops in 2.5 hours. After continuing the heat preservation reaction for 1 hour, add 4.5 grams of The isopropanolamine is partially neutralized, the pH value of the solution is adjusted to 6-7 with sodium hydroxide solution, and water is replenished to obta...

Embodiment 3

[0034] Add 210 g of water, 200 g of methacryl alcohol polyoxyethylene ether (HPEG5000), 3.2 g of propyl acrylate, and 3.0 g of ammonium persulfate into a 1000 ml round-bottomed three-necked flask as the reaction bottom liquid.

[0035] Prepare solution A: mix 30g of acrylic acid, 3.0g of N-N dimethylacrylamide and 40g of water and put them in the dropping funnel.

[0036] Preparation of solution B: mix 0.5 g of Diaoba, 1.5 g of mercaptopropionic acid, 0.8 g of vitamin C and 60 g of water and put them in the dropping funnel.

[0037] Stir until the monomers in the flask are dissolved, and raise the temperature to 50°C. Immediately start adding liquid A and liquid B dropwise at the same time. Liquid A drops in 3.0 hours, and liquid A drops in 3.5 hours. After continuing to keep warm for 0.5 hours, add 4.8 grams of three The propanolamine is partially neutralized, the pH value of the solution is adjusted to 6-7 with a sodium hydroxide solution, and water is replenished to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com