Preparation method of quaternary ammonium salt type hydrophilic ultraviolet curing resin

A curing resin and hydrophilic technology, applied in polyether coatings, coatings, etc., can solve problems affecting continuous anti-fog performance, low polymerization activity, residue, etc., achieve excellent hydrophilic performance, simple preparation, and hydrophilic Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

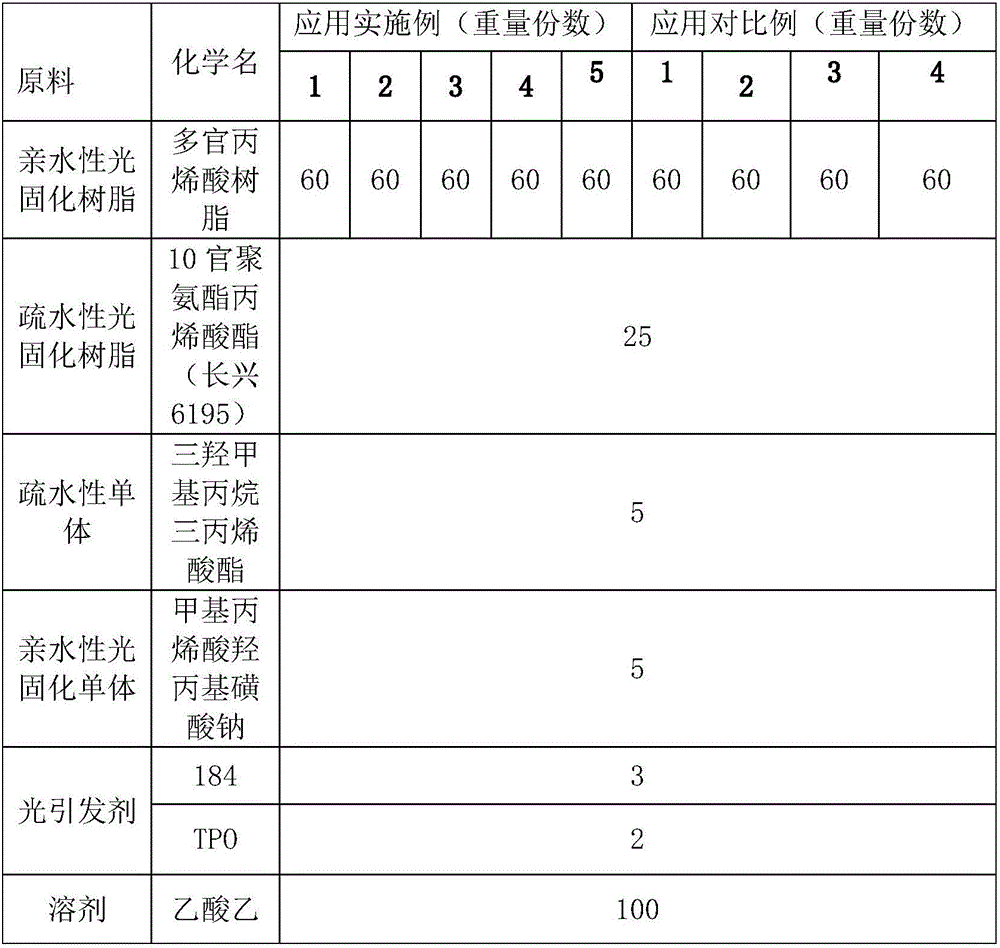

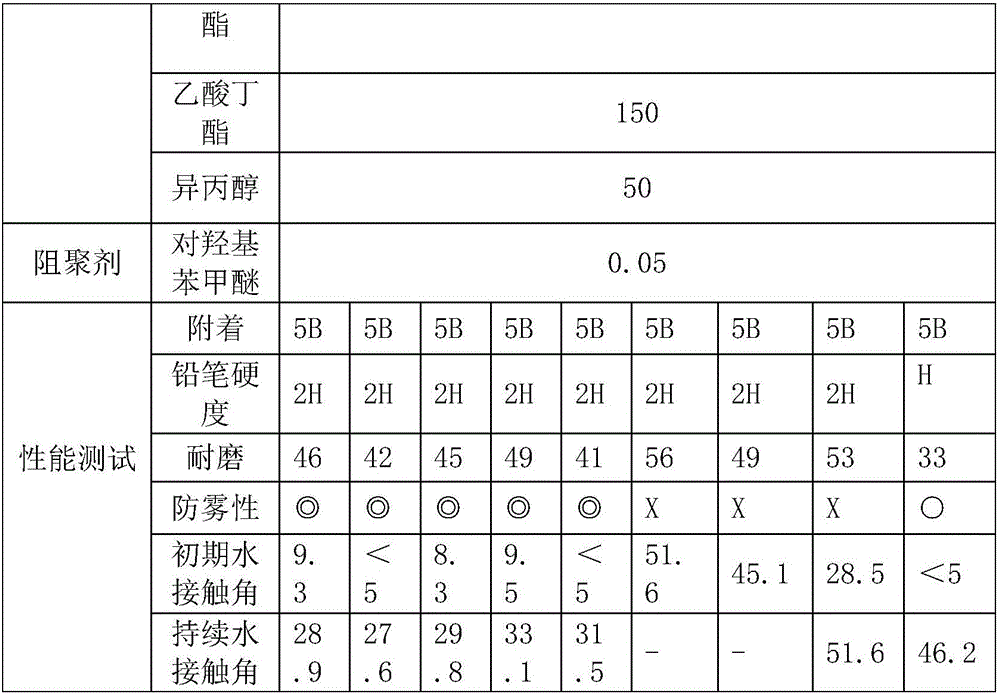

Examples

Embodiment 1

[0031] This embodiment relates to a preparation method of a quaternary ammonium salt type hydrophilic ultraviolet light curing resin, which specifically includes the following steps:

[0032] In the 250 milliliter four-necked bottle that is equipped with mechanical stirring, thermometer, nitrogen gas introduction device, add ethanol (70 grams), polymerization inhibitor p-hydroxyanisole (0.14 grams), polyetheramine D400 (2.30 grams, 5mmol) and 80% acryloyloxyethyltrimethylammonium chloride aqueous solution (24.2 g, 10 mmol), reacted at room temperature for 1.5 hours, FT-IR could not detect 810 cm- 1 At the absorption peak of the double bond, the first step reaction ends. Then add ethoxy dipentaerythritol hexaacrylate (EO96mol) (48.02 grams, 10mmol), heat up to 45 ° C for 3 hours, FT-IR can not detect 3400-3300cm- 1 The absorption peak of the secondary amine is at the end of the reaction, and a light yellow transparent liquid is obtained. Then precipitate with n-hexane, and th...

Embodiment 2

[0034] This embodiment relates to a preparation method of a quaternary ammonium salt type hydrophilic ultraviolet light curing resin, which specifically includes the following steps:

[0035]In the 250 milliliter four-necked bottle that is equipped with mechanical stirring, thermometer, nitrogen gas introduction device, add ethanol (78 grams), polymerization inhibitor p-hydroxyanisole (0.16 grams), polyetheramine D400 (2.30 grams, 5mmol) and 80% acryloyloxyethyltrimethylammonium chloride aqueous solution (24.2 g, 10 mmol), reacted at room temperature for 1.5 hours, FT-IR could not detect 810 cm- 1 At the absorption peak of the double bond, the first step reaction ends. Then add ethoxy pentaerythritol tetraacrylate (EO120mol) (56.32 grams, 10mmol), heat up to 45 ° C for 3 hours, FT-IR can not detect 3400-3300cm- 1 The absorption peak of the secondary amine is at the end of the reaction, and a light yellow transparent liquid is obtained. Then precipitate with n-hexane, and the...

Embodiment 3

[0037] This embodiment relates to a preparation method of a quaternary ammonium salt type hydrophilic ultraviolet light curing resin, which specifically includes the following steps:

[0038] In a 250 ml four-necked bottle equipped with a mechanical stirrer, a thermometer, and a nitrogen gas introduction device, add ethanol (70 grams), a polymerization inhibitor p-hydroxyanisole (0.14 grams), polyetheramine ED-600 (2.64 grams, 5 mmol ) and 80% acryloyloxyethyltrimethylammonium chloride aqueous solution (24.2 grams, 10mmol), reacted at room temperature for 1.5 hours, FT-IR could not detect 810cm- 1 At the absorption peak of the double bond, the first step reaction ends. Then add ethoxy dipentaerythritol hexaacrylate (EO96mol) (48.02 grams, 10mmol), heat up to 45 ° C for 3 hours, FT-IR can not detect 3400-3300cm- 1 At the absorption peak of the secondary amine, the reaction is terminated to obtain a light yellow transparent liquid, which is then precipitated with n-hexane, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com