A kind of metal foam doped polyaniline electromagnetic shielding material and preparation method thereof

An electromagnetic shielding material and metal foam technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of high density, easy corrosion, high price, etc., and achieve the effect of low density, low production cost and extended effective path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

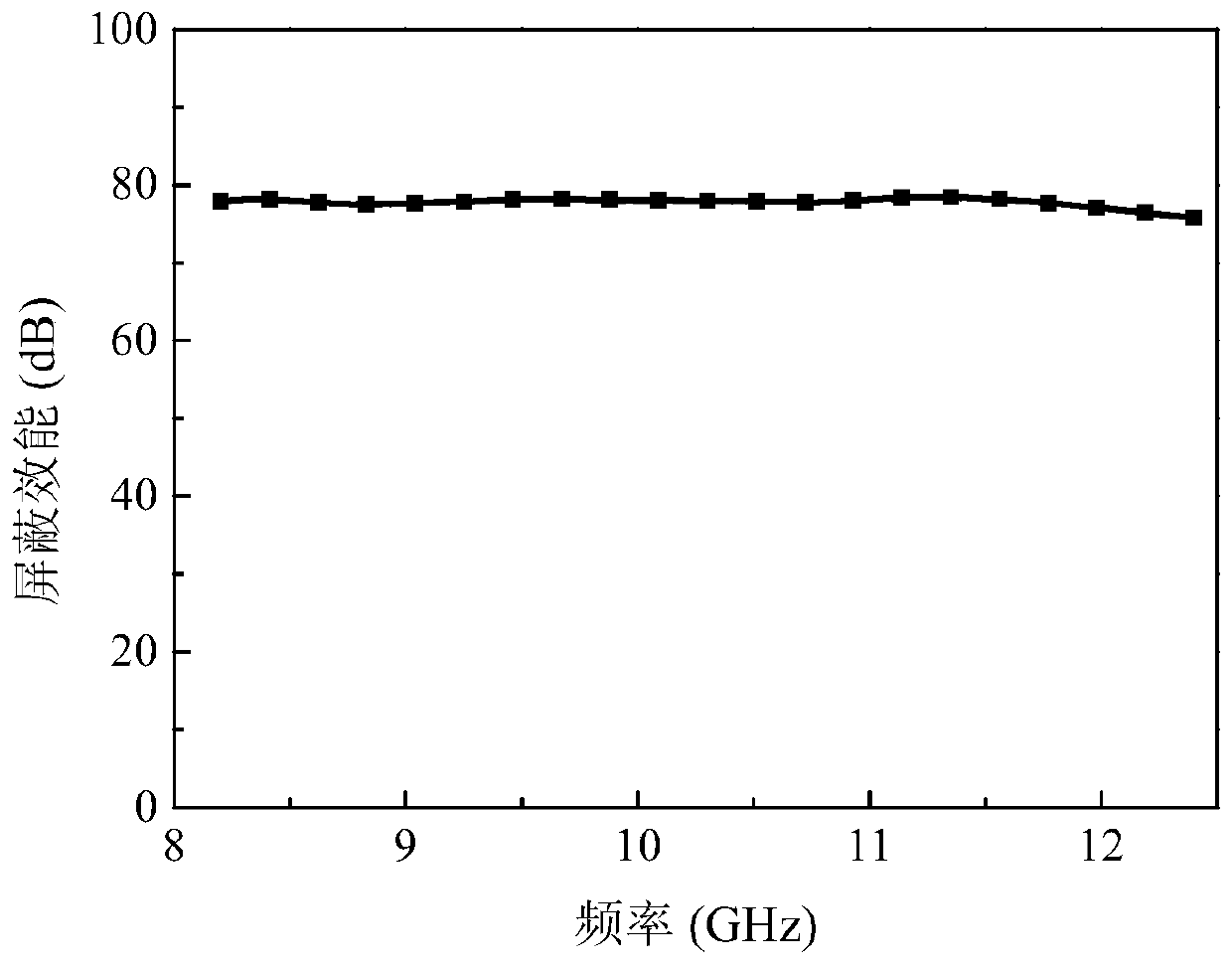

[0024] First configure 1.5mol / L 40mL camphorsulfonic acid solution, and divide it into two parts equally. Mix aluminum foam with a pore density of 130PPI and aniline monomer and let it stand for 30 minutes, then add it to one part of the acid solution, which is called mixture A, wherein the content of aluminum foam is 0.06g / mL, and the content of aniline monomer is 0.12g / mL. Weigh 3.38g of ammonium persulfate and 4.36g of potassium dichromate and dissolve it in another acid solution, and call this solution B. The above mixture A and solution B were stirred uniformly and then cooled to 0°C. The solution B was slowly dropped into the mixture A, and the oxidative polymerization reaction occurred at 0°C, and the reaction time was 4h. After the reaction, the foamed aluminum surface modified with doped polyaniline was taken out, and washed repeatedly with deionized water and absolute ethanol until the filtrate was colorless, transparent and neutral. The obtained product was treat...

Embodiment 2

[0026] The method is the same as in Example 1, except that the metal foam is adjusted to nickel foam. The electromagnetic shielding effectiveness of a material with a thickness of 0.4mm is about 92dB at an electromagnetic wave frequency of 8.2-12.4GHz. The electromagnetic shielding effectiveness of materials is listed in Table 1.

Embodiment 3

[0028] The method is the same as in Example 1, except that the metal foam is adjusted to silver foam. The electromagnetic shielding effectiveness of a material with a thickness of 0.4mm is about 94dB at an electromagnetic wave frequency of 8.2-12.4GHz. The electromagnetic shielding effectiveness of materials is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com