Low viscosity elastic pull paint and production technology thereof

A brushed paint, low-viscosity technology, applied in the field of latex paint, can solve the problems that the brushed paint cannot be poured out directly, the construction is laborious, and the motor is easy to burn out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

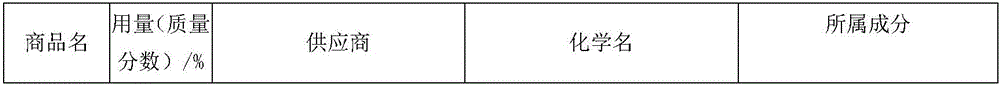

[0026] Embodiment 1: the production recipe of low-viscosity elastic brushed paint, as shown in the table below:

[0027]

[0028]

[0029] The production process is:

[0030] (1) At a rotational speed of 800 r / min, 20.25% by mass of water and 0.2% by mass of hydroxyethyl cellulose ether were successively added to the disperser.

[0031] (2) Adjust the speed of the disperser to 1600r / min, add 0.2% bentonite to the disperser in turn, and keep stirring at 1600r / min for 15 minutes.

[0032] (3) Adjust the rotating speed of the disperser to be 800r / min, and add 0.1% mass fraction of organic silicon defoamer, 0.1% mass fraction of pH regulator, and 0.5% mass fraction of polycarboxylate dispersant to the disperser successively And 0.2% mass fraction of alkylphenol polyoxyethylene ether wetting agent.

[0033] (4) Adjust the rotating speed of the disperser to 1600r / min, add 15% mass fraction of rutile titanium dioxide and 30% mass fraction of heavy calcium carbonate to the dis...

Embodiment 2

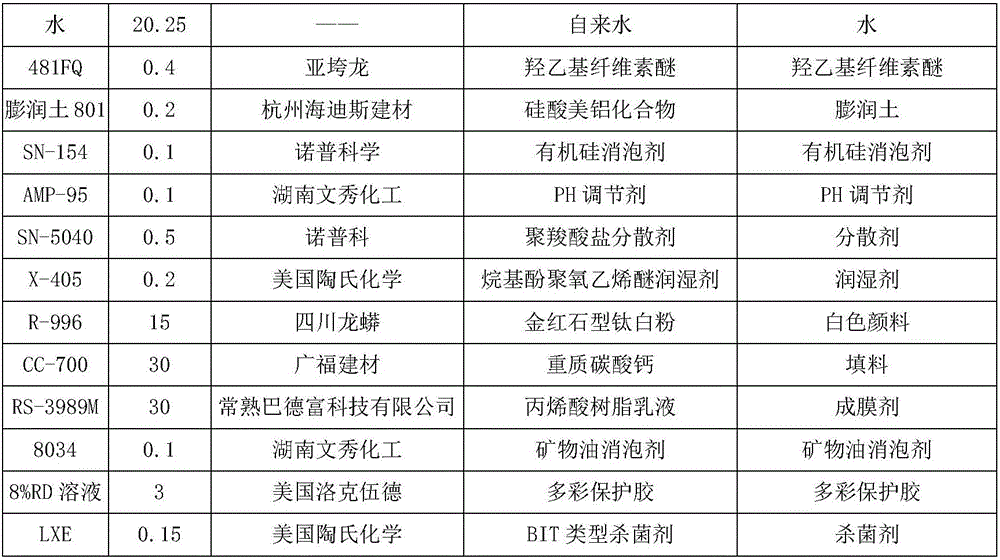

[0035] Embodiment 2: the production prescription of low-viscosity elastic brushed paint, as shown in the table below:

[0036]

[0037]

[0038] The production process is:

[0039] (1) At a rotational speed of 800 r / min, add 23.3% by mass of water and 0.2% by mass of hydroxyethyl cellulose ether into the disperser in sequence.

[0040] (2) Adjust the speed of the disperser to 1600r / min, add 0.2% bentonite to the disperser in turn, and keep stirring at 1600r / min for 15 minutes.

[0041] (3) Adjust the rotating speed of the disperser to be 800r / min, and add 0.1% mass fraction of organic silicon defoamer, 0.1% mass fraction of pH regulator, and 0.5% mass fraction of polycarboxylate dispersant to the disperser successively And 0.15% mass fraction of alkylphenol polyoxyethylene ether wetting agent.

[0042] (4) Adjust the rotational speed of the disperser to 1600r / min, add 15% mass fraction of rutile titanium dioxide and 30% mass fraction of 700-mesh double fly powder to th...

Embodiment 3

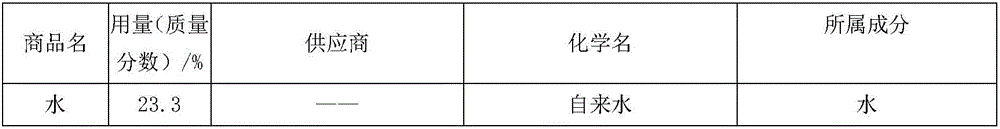

[0044] Embodiment 3: the production recipe of low-viscosity elastic brushed paint, as shown in the table below:

[0045]

[0046]

[0047] The production process is:

[0048] (1) At a rotational speed of 800 r / min, add 32% by mass of water and 0.25% by mass of hydroxyethyl cellulose ether into the disperser in sequence.

[0049] (2) Adjust the rotating speed of the disperser to 1600r / min, add 0.25% bentonite in turn to the dispersing machine, and maintain the rotating speed of 1600r / min to continue stirring for 15 minutes.

[0050] (3) Adjust the rotating speed of the disperser to be 800r / min, and add 0.15% mass fraction of organic silicon defoamer, 0.1% mass fraction of pH regulator, and 0.3% mass fraction of polycarboxylate dispersant to the disperser in turn And 0.15% mass fraction of alkylphenol polyoxyethylene ether wetting agent.

[0051](4) Adjust the rotational speed of the disperser to 1600r / min, add 13.25% mass fraction of rutile titanium dioxide and 25% mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com