Bacillus capable of promoting production of alcohol and flavor substances from saccharomyces cerevisiae and application thereof

A technology of Bacillus and Saccharomyces cerevisiae, applied in the field of bioengineering, can solve the problems of difficulty in improving yeast ethanol and flavor metabolism at the same time, low liquor yield, and decreased liquor yield, and solve the problem that it is difficult to simultaneously improve liquor yield and flavor quality Improve and enhance alcohol and flavor metabolism, improve the effect of alcohol yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

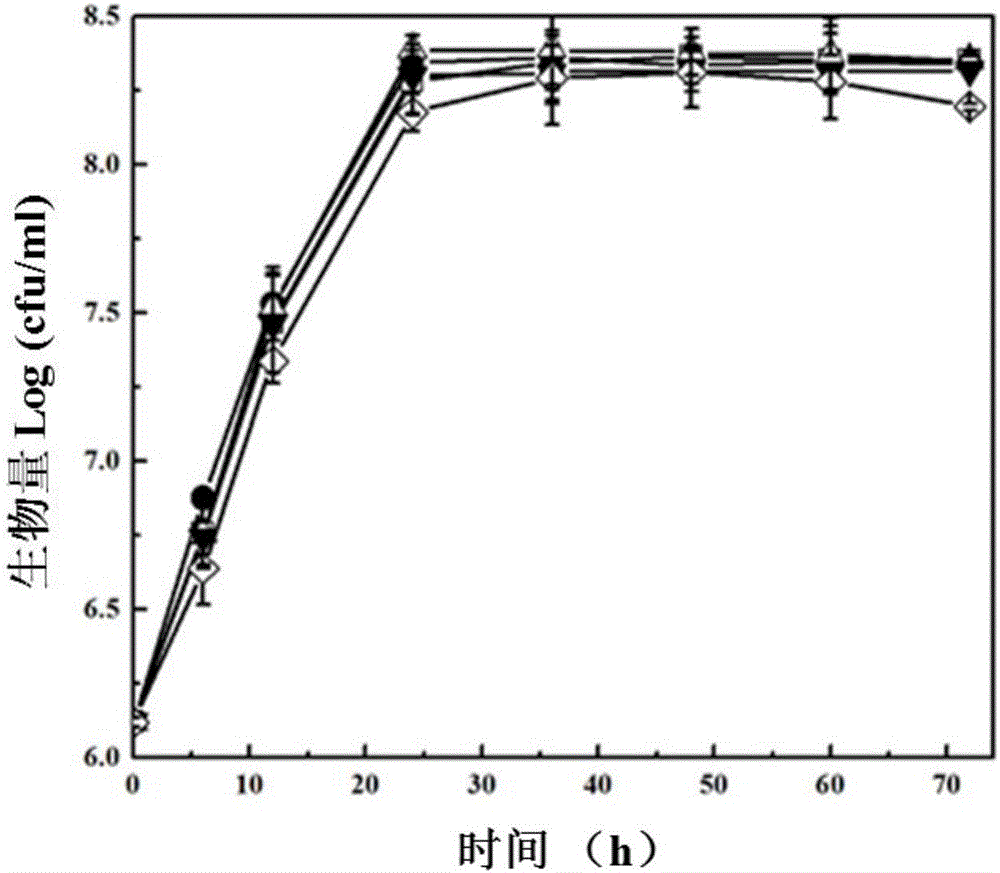

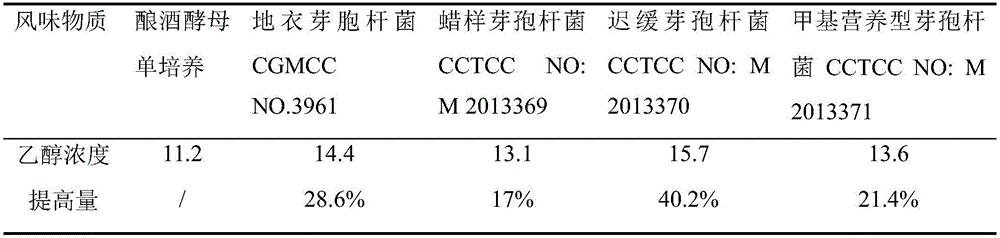

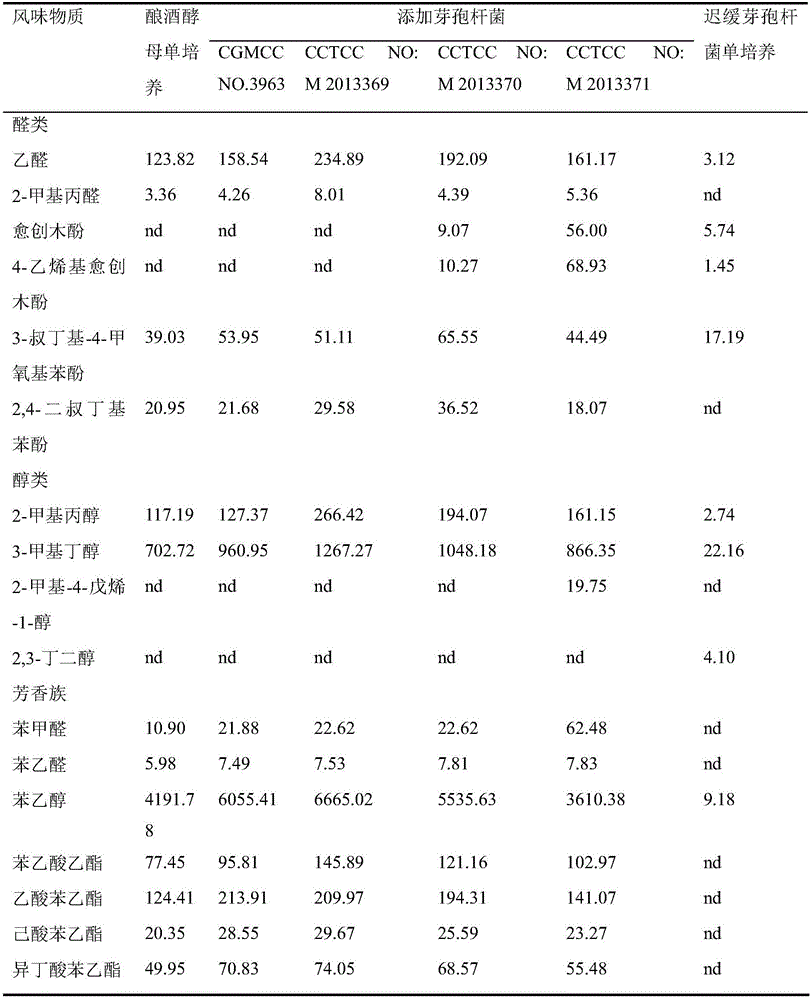

[0036] The mixed culture of embodiment 1 saccharomyces cerevisiae and bacillus

[0037] Saccharomyces cerevisiae seed solution: Pick a ring of Saccharomyces cerevisiae sludge and inoculate it in YEPD liquid medium, and culture at 30°C, 200rpm for 16h. Bacillus seed solution: Pick a ring of Bacillus sludge and inoculate it in LB liquid medium, and cultivate it at 37°C and 200rpm for 16h. Prepare sorghum extract juice, inoculate Saccharomyces cerevisiae seed liquid and Bacillus seed liquid, the final concentration of both is 1×10 6 cfu / mL. Cultivate at 30°C, 200 rpm. Sampling was carried out to measure the concentration of bacteria by plate coating; cultured for 24 to 48 hours, the bacteria liquid was centrifuged at 8000rpm for 10 minutes, and the concentration of ethanol and the components and contents of flavor substances were measured. The change curve of Saccharomyces cerevisiae cell concentration with time is shown in figure 1 , the changes of ethanol concentration are ...

Embodiment 2

[0048] Example 2 Bacillus is used in the production of brewed wine to improve the yield and quality of brewed wine

[0049] Bacillus CCTCC NO:M 2013369 and CCTCC NO:M 2013370 of the present invention are respectively made into liquid or solid inoculum, which are mixed with koji species or fermentation raw materials for fermentation.

[0050] The preparation method of the liquid bacterial agent: the activated seed liquid is inoculated in the sterilized liquid medium at an inoculation amount of 1-5% (w / w) (that is, 1-5 g of the seed liquid is inoculated per 100 g of liquid medium), Cultivate at 25-40°C for 24h-72h.

[0051] The liquid medium is a sorghum extract medium, and the production method is as follows: after crushing 20-200 g of sorghum samples, add 1-4 times the amount of water in terms of mL / g, cook for 1-5 hours to form a paste, and add 10 ~50 units / g of glucoamylase, keep at 40~100°C for 2~10h, filter and centrifuge the obtained filtrate, the sugar content is 10~15°...

Embodiment 3

[0062] The mixed culture of embodiment 3 saccharomyces cerevisiae and bacillus

[0063] Saccharomyces cerevisiae, B.licheniformis CGMCC NO.3963, B.lentus CCTCC NO:M 2013370 were prepared into seed solution respectively. Mix B.licheniformis CGMCC3963 and B.lentus CCTCC NO:M 2013370 at a ratio of 1:1, and inoculate them with Saccharomyces cerevisiae in YPD medium, so that the number of yeast and bacillus after inoculation is 10 4 pcs / mL, 10 10 cells / mL, cultured statically at 30°C for 72h. It was found that, compared with individual cultures, acetaldehyde, 2-methylpropanal, 3-tert-butyl-4-methoxyphenol, 2-methylpropanol, 3-methylbutanol, benzaldehyde, benzene Acetaldehyde, ethyl phenylacetate, phenylethyl acetate, phenylethyl caproate, phenylethyl isobutyrate, 2,3-dihydrobenzofuran, 2-methylpropanoic acid, caproic acid, caprylic acid, capric acid , farnesol, β-citronellol and other substances have a certain degree of increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com