Purification method of starch sugar

A purification method and technology of starch sugar, which is applied in the field of starch sugar processing, can solve problems such as production abnormalities, adverse environmental effects, and introduction of insoluble impurities, and achieve the effects of saving treatment costs, prolonging the filtration cycle, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

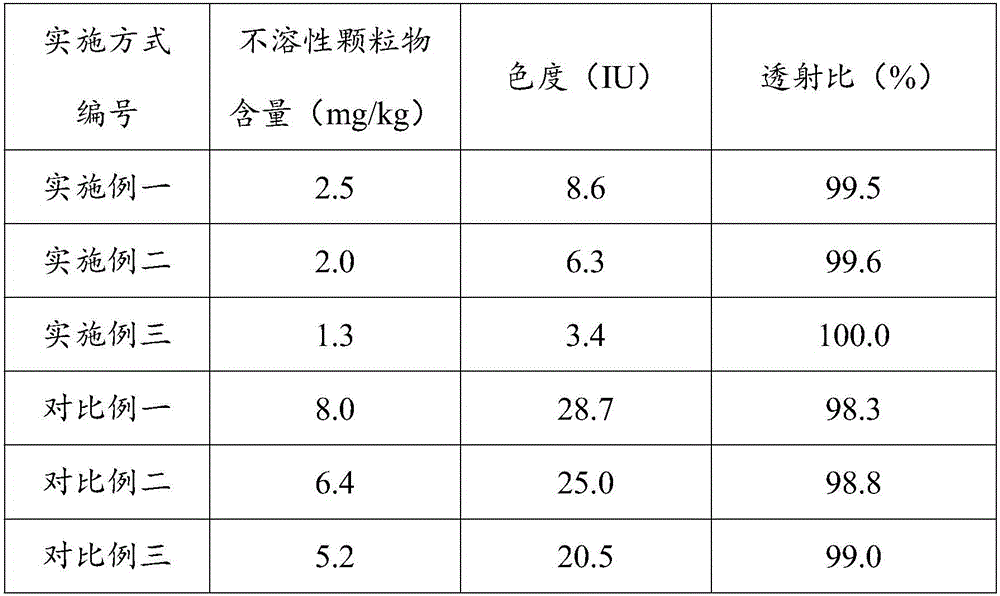

Examples

Embodiment 1

[0060] (1) KDF50 candle filter is filled with clean water at 80°C and exhausted. Fill the pre-coating tank with about 2 / 3 liquid level of clean water at 80°C and add 45kg of cellulose and 15kg of diatomaceous earth. Stir for 15 minutes and set the parameters (pre-coating tank) Coating flow is 20m 3 / h, the precoating time is 30min, and the cycle time is 15min) Precoat the cellulose and diatomaceous earth on the filter candle to form a composite precoat.

[0061] (2) to starch sugar liquid (glucose dry basis is 15.62%wt, and maltose dry basis is 13.20%wt, transmittance is 50.2%, chromaticity is 65.53IU, dry matter content is 20.0%wt, protein, grease and crude fiber The total amount is 0.50%wt of the starch sugar solution) Add diatomaceous earth according to 0.15%wt, stir for 30min, at 80°C with 0.2m 3 / (m 2 The speed of h) is introduced into the filter candle from the liquid inlet of the candle filter, and the filtrate is obtained from the liquid outlet of the candle filter. ...

Embodiment 2

[0064] (1) KDF50 candle filter is filled with clean water at 65°C and exhausted. Fill the pre-coating tank with about 2 / 3 liquid level of clean water at 65°C and add 40kg of cellulose and 20kg of diatomaceous earth. Stir for 15 minutes and set the parameters (pre-coating tank). Coating flow is 20m 3 / h, the precoating time is 30min, and the cycle time is 15min) Precoat the cellulose and diatomaceous earth on the filter candle to form a composite precoat.

[0065] (2) to the starch sugar solution (glucose dry basis is 0.91%wt, maltose dry basis is 46.85%wt, transmittance is 82.6%, chroma is 50.05IU, dry matter content is 35.5%wt, protein, oil and crude fiber The total amount is 0.10%wt of the starch sugar solution) Add diatomaceous earth according to 0.1%wt, stir for 30min, 3 / (m 2 The speed of h) is introduced into the filter candle from the liquid inlet of the candle filter, and the filtrate is obtained from the liquid outlet of the candle filter.

[0066] (3) The filtrate...

Embodiment 3

[0068] (1) KDF50 candle filter is filled with clear water at 50°C and exhausted. Fill the pre-coating tank with about 2 / 3 liquid level of clear water at 50°C and add 36kg of cellulose and 24kg of diatomaceous earth. Stir for 15 minutes and set the parameters (pre-coating tank). Coating flow is 20m 3 / h, the precoating time is 30min, and the cycle time is 15min) Precoat the cellulose and diatomaceous earth on the filter candle to form a composite precoat.

[0069] (2) to the starch sugar solution (the dry basis of glucose is 39.83%wt, the dry basis of fructose is 55.67%, the dry basis of maltose is 0.22%wt, the transmittance is 95.0%, the chroma is 33.89IU, and the dry matter content is 60.0%wt , the total amount of protein, oil and crude fiber is 0.05%wt of the starch sugar solution) add diatomaceous earth according to 0.015%wt, stir for 30min, at 50 ℃ with 0.8m 3 / (m 2 The speed of h) is introduced into the filter candle from the liquid inlet of the candle filter, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com