A charge-trapping memory based on a single-layer barium strontium titanate thin film and its preparation method

A barium strontium titanate thin film and charge trapping technology, which is applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems of poor fatigue resistance, small storage window, poor stability of high and low state capacitance and flat band voltage, etc. Excellent fatigue characteristics, fast switching speed, and stable maintenance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

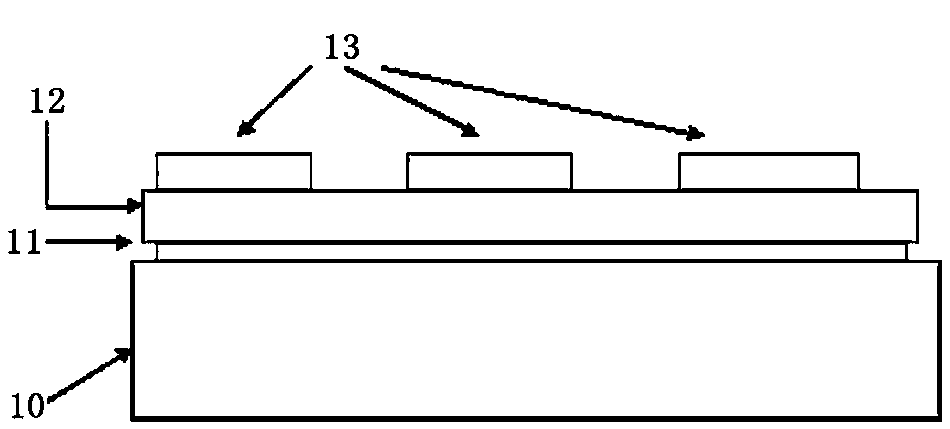

[0036] The structure of the charge trapping memory prepared by the present invention is as follows: figure 2 As shown, its structure from bottom to top is p-Si substrate 10, SiO 2 Tunneling layer 11 , BST trapping barrier layer 12 and Pd electrode layer 13 .

[0037] Wherein the p-Si substrate 10 is 100 crystal orientation; BST capture barrier layer 12 is grown on the p-Si substrate 10 by the method for magnetron sputtering, and its thickness is 5 ~ 100nm, under the preferred 10 ~ 50nm, its storage The window is bigger.

[0038] Of which SiO 2The tunneling layer 11 is formed by forming the BST trapping barrier layer 12 on the p-Si substrate 10 and then performing an annealing process. The annealing process refers to raising the temperature from room temperature to 600°C in an oxygen atmosphere for 20~40s. , keep warm for 2~10min, and then cool down from 600℃ to room temperature in 1~5min; the final formed SiO 2 The thickness of the tunneling layer is 2~4nm.

[0039] The ...

Embodiment 2

[0041] The preparation method of the resistive memory provided by the present invention comprises the following steps:

[0042] (1) Clean the p-type Si substrate (p-Si substrate) with 100 crystal orientation in acetone, alcohol and deionized water with ultrasonic wave for 5 minutes respectively, then take it out and put it into HF solution (the mass ratio concentration of HF and water is 3 :1) Clean in medium, take it out and wash it in deionized water, and finally take it out and use N 2 blow dry;

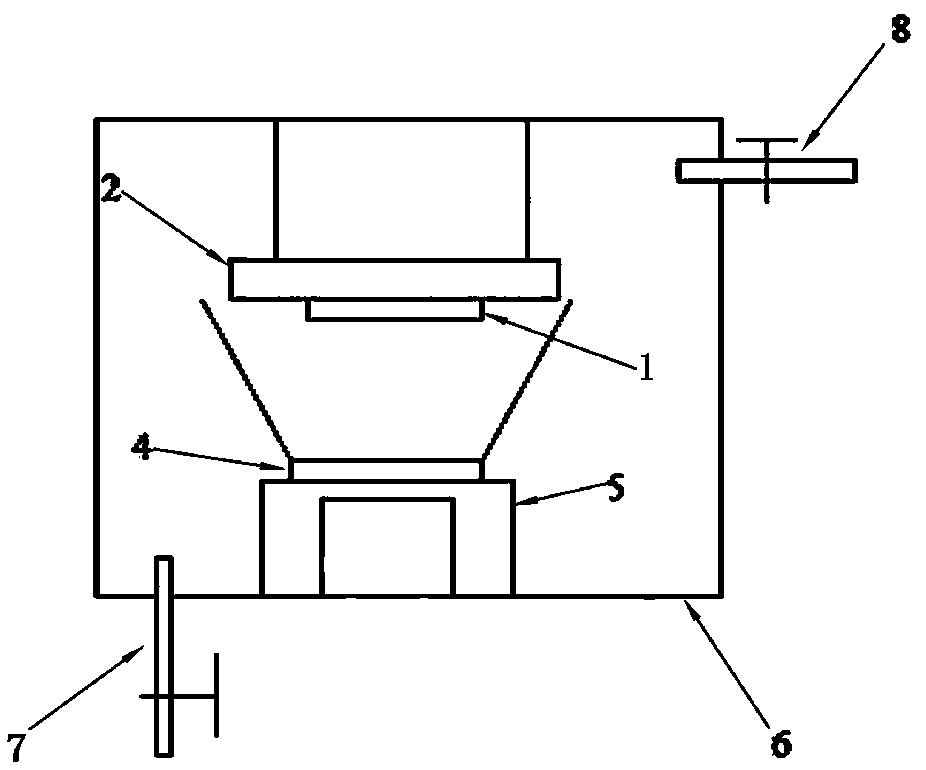

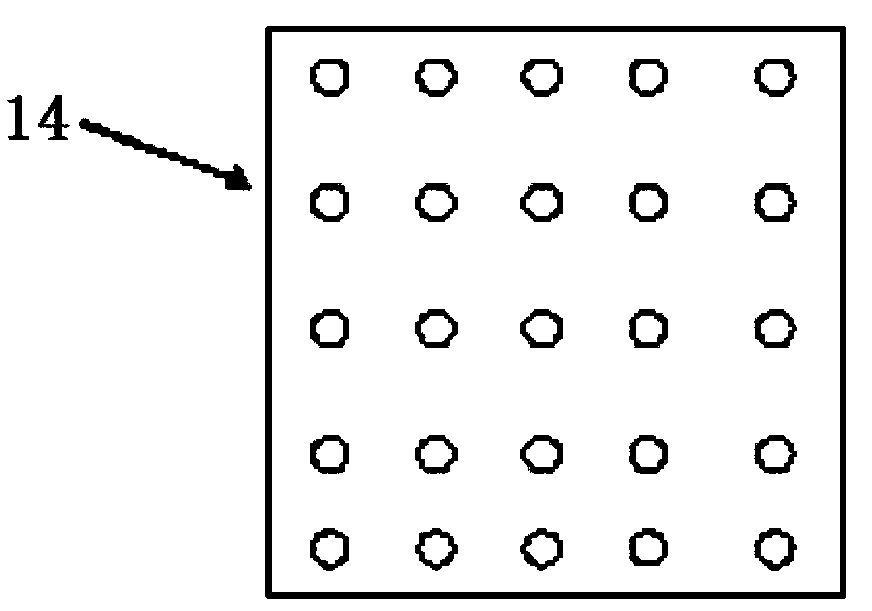

[0043] (2) using such as figure 1 In the shown magnetron sputtering equipment, a target stage 5 is arranged under the substrate stage 2 in the growth chamber 6, and a target material 4 is placed on the top of the target stage 5; the growth chamber 6 of the magnetron sputtering apparatus is opened, and the BST The target is fixed on the target stage 5 of the magnetron sputtering equipment, and the p-Si substrate is placed on the substrate holder 1 and then fixed on the substrate ...

Embodiment 3

[0047] Embodiment 3 performance test

[0048] The charge-trapping memory prepared in Example 2 was tested for performance, and its C-V curve is shown in Figure 4, and the storage window-scanning voltage characteristics are as follows Figure 5 shown. The figure shows that the scanning voltage starts to increase from 2V at a time. When the scanning voltage increases to 6V, that is, when the scanning voltage is +6V→-6V→+6V, the storage window of the storage device begins to open, and the storage device begins to have storage performance. As the scanning voltage increases, the storage window gradually increases. When the scanning voltage reaches 14V, it presents a large storage window of 8.1V, which indicates a very good storage effect.

[0049] The high and low state retention characteristics of the charge trapping memory prepared in embodiment 2 were measured, and the results are shown in Figure 6 .

[0050] The flat-band voltage retention characteristics of the charge-tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com