Soft-package aluminum-plastic film for lithium ion battery and preparation method of soft-package aluminum-plastic film

A lithium-ion battery and aluminum-plastic film technology, which is applied to the soft-packed aluminum-plastic film of lithium-ion batteries and its preparation field, can solve the problems of the inner layer of the aluminum foil film, such as insufficient corrosion resistance and abrasion resistance, and achieve corrosion resistance Strong, improved service life, stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

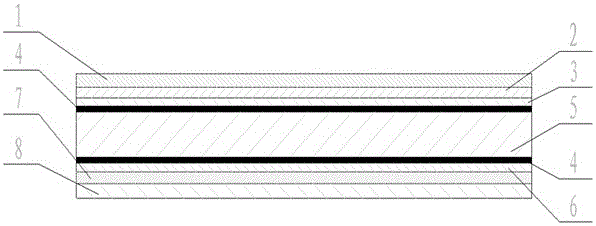

[0052] Soft aluminum-plastic film for lithium-ion batteries, its structure is as follows figure 1 As shown, from outside to inside are PTFE layer wear-resistant layer 1, co-extruded layer 2, bonding layer 3, diamondene-nickel-phosphorus coating 4, aluminum foil layer 5, diamondene-nickel-phosphorus coating 4 , a thermosetting plastic layer 6, an adhesive layer 7, and a heat-sealing layer 8.

[0053] The thickness of the PTFE wear-resistant layer is 10 microns, the co-extrusion layer is 4 microns, the bonding layer is 10 microns, the diamondene-nickel-phosphorus composite coating is 2 microns, the aluminum foil layer is 90 microns, and the diamondene-nickel-phosphorus composite coating is 2 microns , Thermosetting plastic 5 microns, adhesive layer 10 microns, heat seal layer 15 microns.

[0054] Among them, hot-melt glue is used for the bonding layer, and the hot-melt glue is adjusted to a solid content of 45%; the ratio of polyethylene and nylon in the co-extruded layer is 1:...

Embodiment 2

[0075] Soft aluminum-plastic film for lithium-ion batteries, its structure is as follows figure 1 As shown, from outside to inside are PTFE layer wear-resistant layer 1, co-extruded layer 2, bonding layer 3, diamondene-nickel-phosphorus coating 4, aluminum foil layer 5, diamondene-nickel-phosphorus coating 4 , a thermosetting plastic layer 6, an adhesive layer 7, and a heat-sealing layer 8.

[0076] The thickness of the PTFE wear-resistant layer is 8 microns, the co-extrusion layer is 5 microns, the bonding layer is 15 microns, the diamondene-nickel-phosphorus composite coating is 2 microns, the aluminum foil layer is 90 microns, and the graphene-nickel-phosphorus composite coating is 2 microns , Thermosetting plastic 7 microns, adhesive layer 15 microns, heat seal layer 12 microns.

[0077] Among them, hot-melt glue is used for the bonding layer, and the hot-melt glue is adjusted to a solid content of 45%; the ratio of polyethylene and nylon in the co-extrusion layer is 1:0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com