Secondary battery and electrolyte injection method

A secondary battery and liquid injection technology, applied in secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of increased impedance of the full cell, deteriorated cycle and other dynamic performance, and prevent direct contact with side reactions. , Avoid the interaction between the positive electrode film-forming additive and the negative electrode interface, and the effect of the injection method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present application will be further described below with reference to specific embodiments. It should be understood that these examples are only used to illustrate the present application and not to limit the scope of the present application.

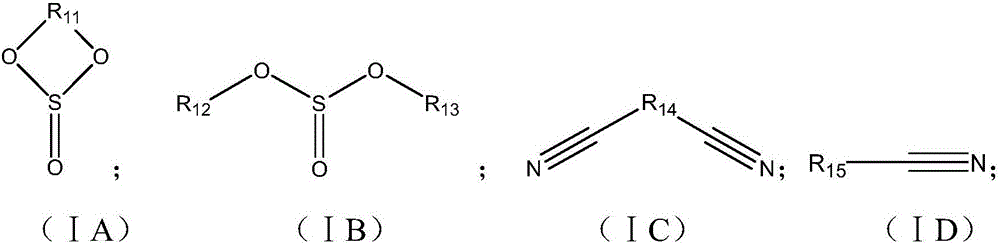

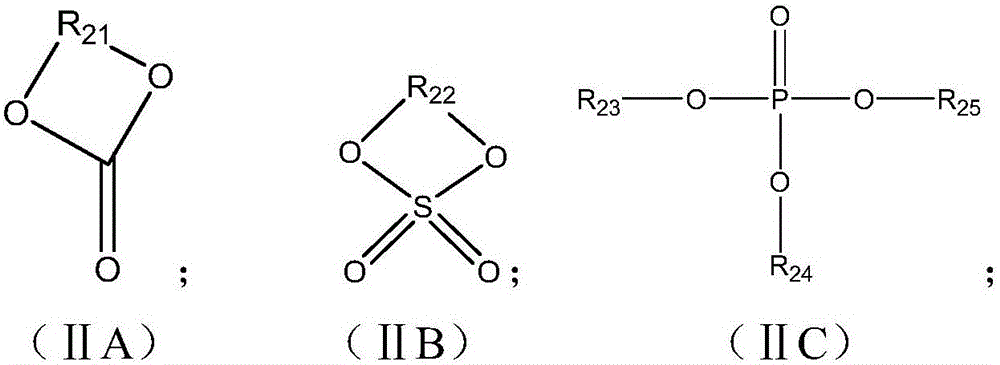

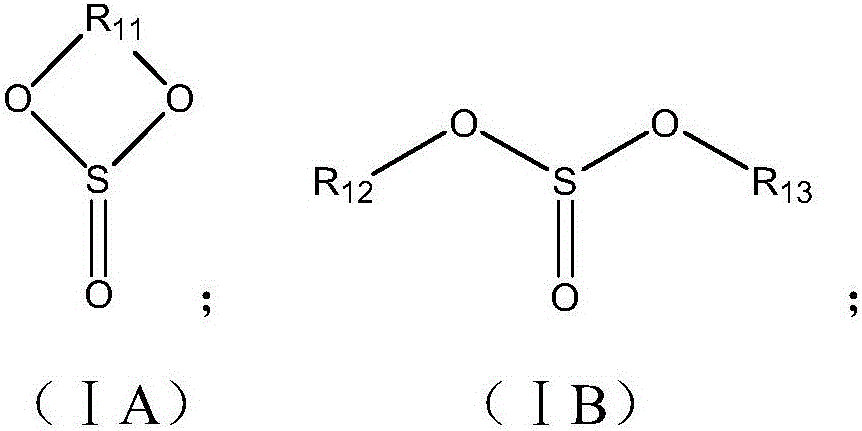

[0027] The present application relates to a secondary battery, comprising a positive electrode piece, a negative electrode piece, a diaphragm and an electrolyte, a high nickel ternary positive electrode material in the positive electrode active material of the positive electrode piece, and the electrolyte includes a solvent, an electrolyte salt and a film-forming additive; The solution consists of the electrolyte S1 injected into the secondary battery for the first time and the electrolyte S2 injected into the secondary battery for the second time. The film-forming additive in the electrolyte S1 is the negative film-forming additive, and the film-forming additive in the electrolyte S2 The additive is a positive electrode film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com