A kind of flexible lithium-ion battery negative electrode and its preparation method and flexible lithium-ion battery

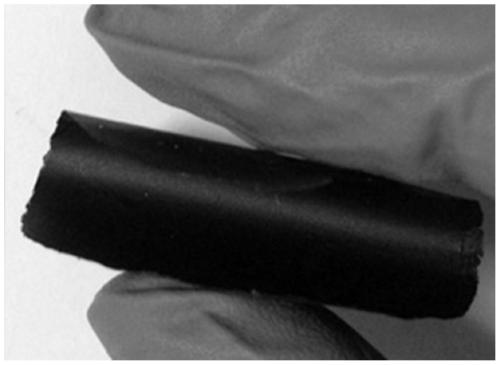

A technology for lithium-ion batteries and negative electrode active materials, applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of unsatisfactory fast charging performance of flexible negative electrodes, impossibility of fast charging, poor conductivity of negative electrodes, etc. Achieve the effect of overcoming corrosion, good bendability, and strong bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

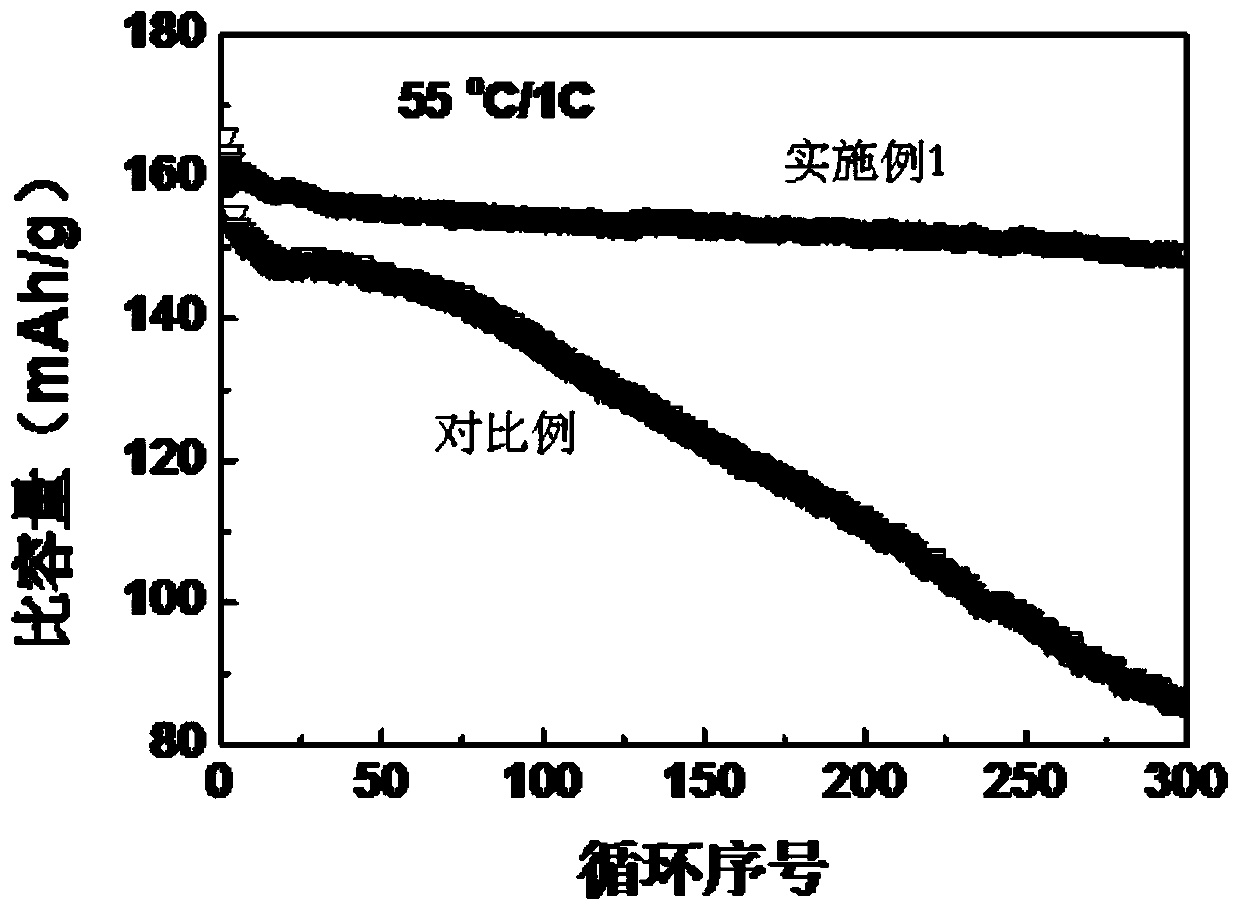

Embodiment 1

[0038] A method for preparing a flexible lithium-ion battery negative electrode, comprising the following steps:

[0039] (1) Preparation of black phosphorus nanoparticles

[0040] Add black phosphorus powder and cetyltrimethylammonium bromide to the organic solvent obtained by combining polylactic acid (PLA) and dimethylformamide in a mass ratio of 1:5 and mix evenly. Ultrasonic treatment in a water bath for 7 hours, vacuum filtration, and vacuum drying to obtain a few-layer black phosphorus flake material, that is, black phosphorus nanoparticles;

[0041] (2) Preparation of porous polymer nanofibrous web

[0042] Weigh 1.5g of polyacrylonitrile with a molecular weight of 100,000 and add it to 12g of N,N-dimethylformamide, heat to 55°C and stir magnetically for 10 hours to obtain an electrospinning solution; use the electrospinning solution as a raw material , under the conditions of spinning voltage of 17kV, spinning distance of 16cm, and spinning time of 2.5 hours, electr...

Embodiment 2

[0049] A method for preparing a flexible lithium-ion battery negative electrode, comprising the following steps:

[0050] (1) Preparation of black phosphorus nanoparticles

[0051] Black phosphorus powder and intercalation agent hexadecyltrimethylammonium bromide are added to polycaprolactone (PCL) and dimethylformamide (volume ratio is 1:1) in an organic Mix evenly in the solvent, isolate the air, and ultrasonically treat in a water bath at 65°C for 7 hours, then vacuum filter and vacuum dry to obtain a few-layer black phosphorus flake material, that is, black phosphorus nanoparticles;

[0052] (2) Preparation of porous polymer nanofibrous web

[0053] With embodiment 1;

[0054] (3) Preparation of flexible lithium-ion battery negative electrode

[0055] With embodiment 1.

[0056] Fabrication of Flexible Lithium-ion Coin Cells

[0057] The flexible lithium-ion battery negative electrode prepared in Example 2 of the present invention is used as the negative electrode, th...

Embodiment 3

[0059] A method for preparing a flexible lithium-ion battery negative electrode, comprising the following steps:

[0060] (1) Preparation of black phosphorus nanoparticles

[0061] With embodiment 2;

[0062] (2) Preparation of porous polymer nanofibrous web

[0063] Weigh 1.5g of polyacrylonitrile with a molecular weight of 100,000 and add it to 12g of N,N-dimethylformamide, heat to 55°C and stir magnetically for 10 hours to obtain an electrospinning solution; use the electrospinning solution as a raw material , under the conditions of spinning voltage of 17kV, spinning distance of 16cm, and spinning time of 2.5 hours, electrospinning is completed to obtain polymer nanofiber web; the obtained polymer nanofibrous web is placed in a tube furnace , raising the furnace temperature from room temperature to 300°C at a heating rate of 1.0°C / min, and calcining at a calcination temperature of 300°C for 40 minutes to complete pre-oxidation to obtain a porous polymer nanofibrous web; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com