High-temperature three-element material power battery and preparation method thereof

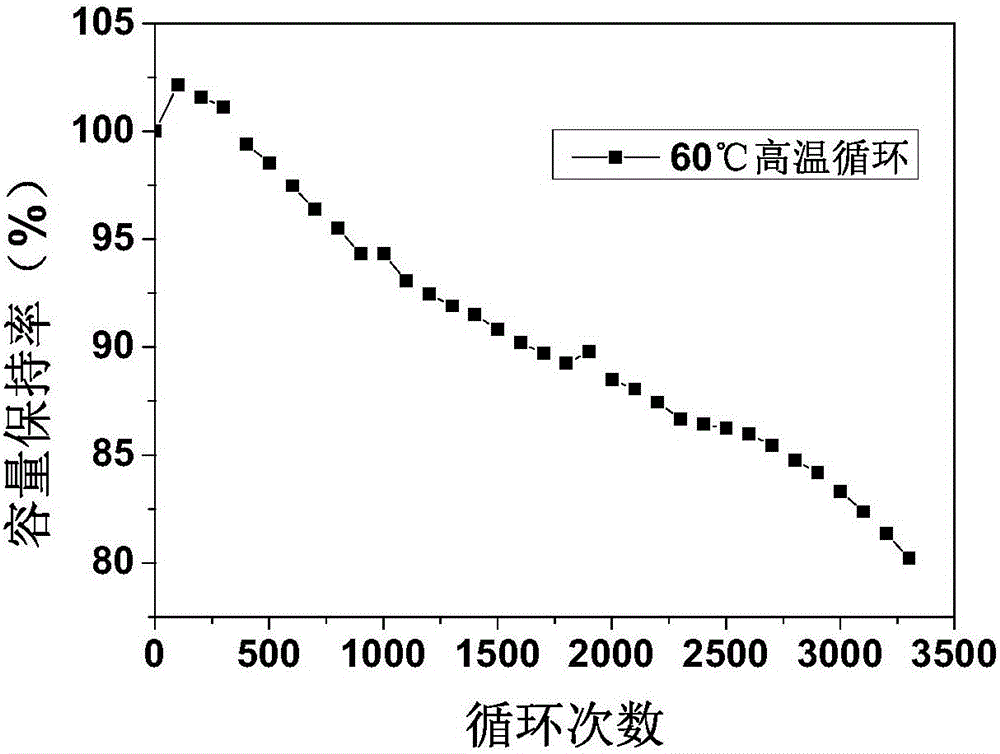

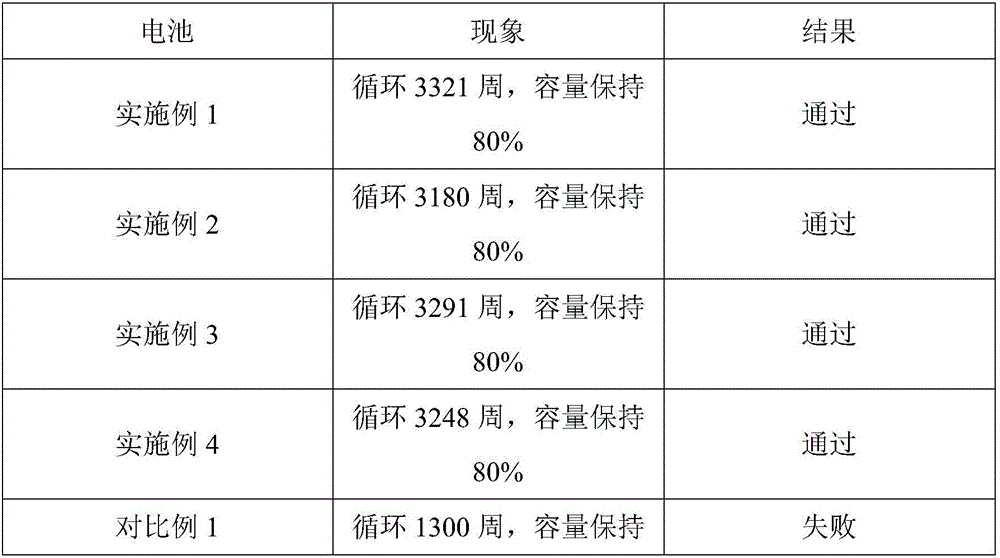

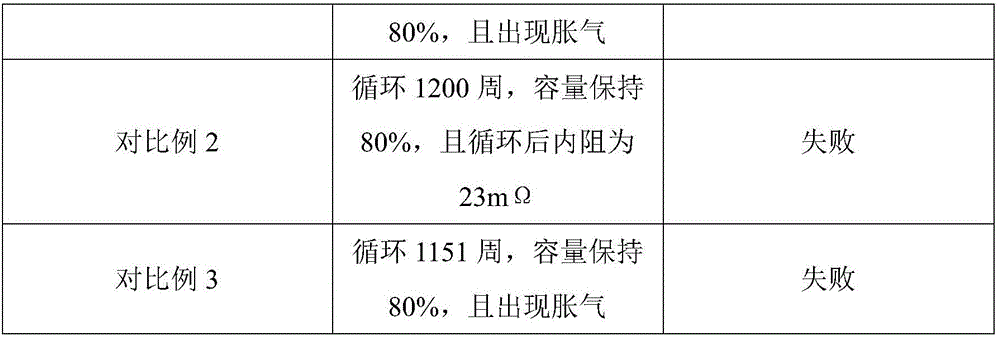

A technology of power battery and ternary material, applied in the field of high temperature ternary material power battery and its preparation, can solve the problems of flatulence, capacity retention rate can only reach 1500 weeks, etc., and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A high-temperature ternary power battery, the positive electrode is a nickel-cobalt-manganese 1:1:1 ternary positive electrode material, the negative electrode uses natural scaly graphite, and the electrolyte is 30% ethylene carbonate, 40% ethyl methyl carbonate and 30% % diethyl carbonate mixed solution, the additives are 2% vinylene carbonate, 2% 1,3-propenyl-carbonic lactone and 2% propylene sulfite; the diaphragm is a coated diaphragm, and the diaphragm The substrate is polypropylene with a thickness of 30 μm; the coating is ceramic; the thickness is 4 μm; the positive current collector: carbon-coated aluminum foil, the thickness of the aluminum foil is 16 μm, and the thickness of the carbon coating is 1 μm; the cover plate is equipped with a discharge valve and a safety valve; The coating thickness is 0.5 μm.

[0038] The preparation method comprises the following steps:

[0039] 1) Mix the ternary material into the NMP solvent, add a conductive agent, and dispers...

Embodiment 2

[0045]A high-temperature ternary power battery, the positive electrode is a nickel-cobalt-manganese 1:1:1 ternary positive electrode material, the negative electrode uses natural scaly graphite, and the electrolyte is 35% ethylene carbonate, 35% ethyl methyl carbonate and 30% % diethyl carbonate mixed solution, the additives are 2.5% vinylene carbonate, 2% 1,3-propenyl-carbonic lactone and 2% propylene sulfite; the diaphragm is a coated diaphragm, and the diaphragm The substrate is polypropylene with a thickness of 28 μm; the coating is ceramic; the thickness is 5 μm; the positive current collector: carbon-coated aluminum foil, the thickness of the aluminum foil is 14 μm, and the thickness of the carbon coating is 1.5 μm; the cover plate is equipped with a discharge valve and a safety valve; The thickness of the silica gel coating is 0.5 μm.

[0046] The preparation method comprises the following steps:

[0047] 1) Mix the ternary material into the NMP solvent, add a conducti...

Embodiment 3

[0053] A high-temperature ternary power battery, the positive electrode is a nickel-cobalt-manganese 1:1:1 ternary positive electrode material, the negative electrode uses natural scaly graphite, and the electrolyte is 30% ethylene carbonate, 35% ethyl methyl carbonate and 35% % diethyl carbonate mixed solution, the additives are 2.5% vinylene carbonate, 2% 1,3-propenyl-carbonic lactone and 2.5% propylene sulfite; the diaphragm is a coated diaphragm, and the diaphragm The substrate is polypropylene with a thickness of 32 μm; the coating is ceramic; the thickness is 3 μm; the positive current collector: carbon-coated aluminum foil, the thickness of the aluminum foil is 12 μm, and the thickness of the carbon coating is 0.5 μm; the cover plate is equipped with a discharge valve and a safety valve; The thickness of the silica gel coating is 0.3 μm.

[0054] The preparation method comprises the following steps:

[0055] 1) Mix the ternary material into the NMP solvent, add a condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com