Carbon nitride and carbon composite nanomaterial and preparation method and application thereof

A composite material and nanomaterial technology, applied in the field of carbon nitride/carbon nanocomposite materials and their preparation, can solve the problems of complex preparation procedures and high cost, and achieve the effect of simple material preparation method and excellent surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

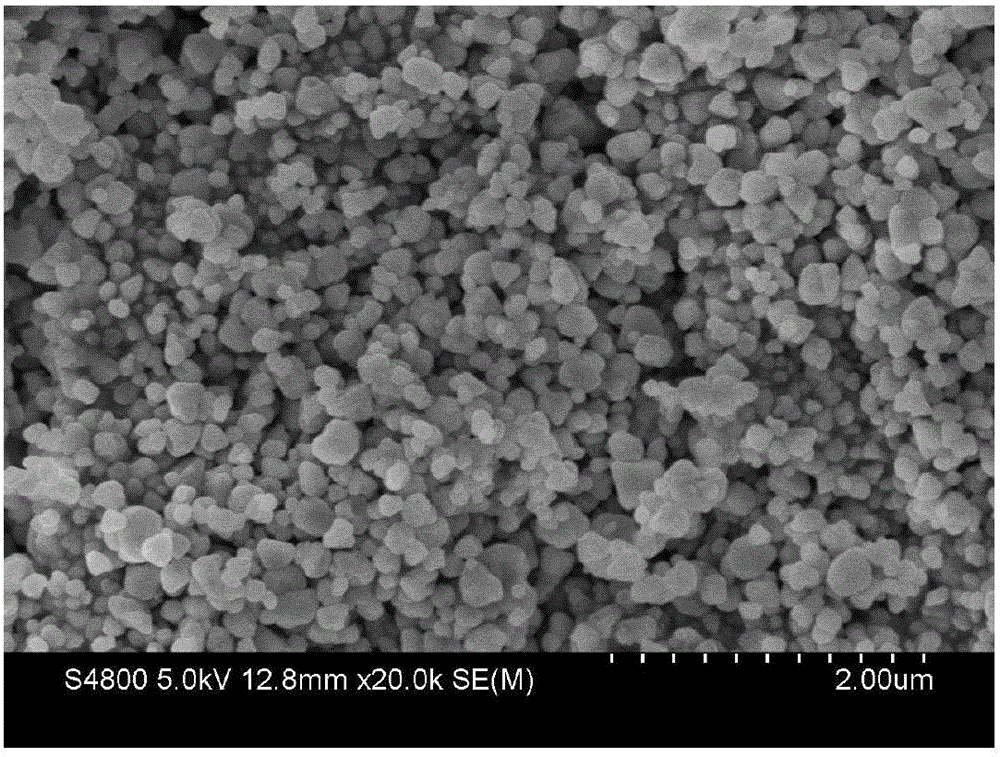

[0022] A preparation method of carbon nitride / carbon nanocomposite material, comprising the steps of:

[0023] (1) Surfactant EO 20 PO 70 EO 20 Dissolve in the solvent ethylene glycol, then add carbon and nitrogen source melamine, stir and mix evenly, then transfer the mixture to a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 110 for 12 hours. After the reaction, the product is centrifuged, washed, dried at 100°C, and finally calcined in a nitrogen atmosphere at 450°C for 5 hours to obtain carbon nitride nanomaterials;

[0024] (2) Carbon source glucose and catalyst ferrocene are dissolved in solvent ethanol to form a uniform and stable solution, the addition of the carbon source is 8g / L, and the catalyst concentration is 0.002mol / L, then take step (1) 4g of the carbon nitride nanomaterial prepared in the above solution was added to the above solution, and then ultrasonically treated at room temperature for 1 h, and then the m...

Embodiment 2

[0026] A preparation method of carbon nitride / carbon nanocomposite material, comprising the steps of:

[0027] (1) Surfactant EO l06 PO 70 EO 106 Dissolve in the solvent methanol, then add carbon and nitrogen source cyanamide, stir and mix evenly, then transfer the mixture to a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 20°C for 8 hours. After the reaction, the product Carry out centrifugation, washing, drying at 80°C, and finally roasting in a nitrogen atmosphere at 550°C for 3 hours to obtain carbon nitride nanomaterials;

[0028] (2) Dissolve carbon source sucrose and catalyst cobaltocene in solvent acetone to form a uniform and stable solution, the addition of the carbon source is 10g / L, and the catalyst concentration is 0.003o1 / L, then take step (1) 5 g of the carbon nitride nanomaterial prepared in the above solution was added to the above solution, and then ultrasonically treated at room temperature for 1.2 h, and the...

Embodiment 3

[0030] A preparation method of carbon nitride / carbon nanocomposite material, comprising the steps of:

[0031] (1) Surfactant EO 132 PO 60 EO 132 Dissolve in the solvent ethylene glycol, then add carbon and nitrogen source melamine, stir and mix evenly, then transfer the mixture to a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 115°C for 10 hours. After the reaction, the product Carry out centrifugation, washing, drying at 90°C, and finally roasting in a nitrogen atmosphere at 550°C for 3 hours to obtain carbon nitride nanomaterials;

[0032] (2) carbon source phenolic resin and catalyzer nickelocene are dissolved in solvent acetone, form uniform and stable solution, the add-on of described carbon source is 15g / L, and catalyst concentration is 0.003mol / L, then takes step (1 ) was added to the above solution, followed by ultrasonic treatment at room temperature for 1.6 h, and then the mixture was transferred to a reaction kettl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com