A Loss Minimal Direct Torque Control Method for Hybrid Excitation Synchronous Motor

A hybrid excitation synchronous and direct torque control technology, applied in the field of electrical transmission, can solve the problems of insufficient constant power operating range and insufficient efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

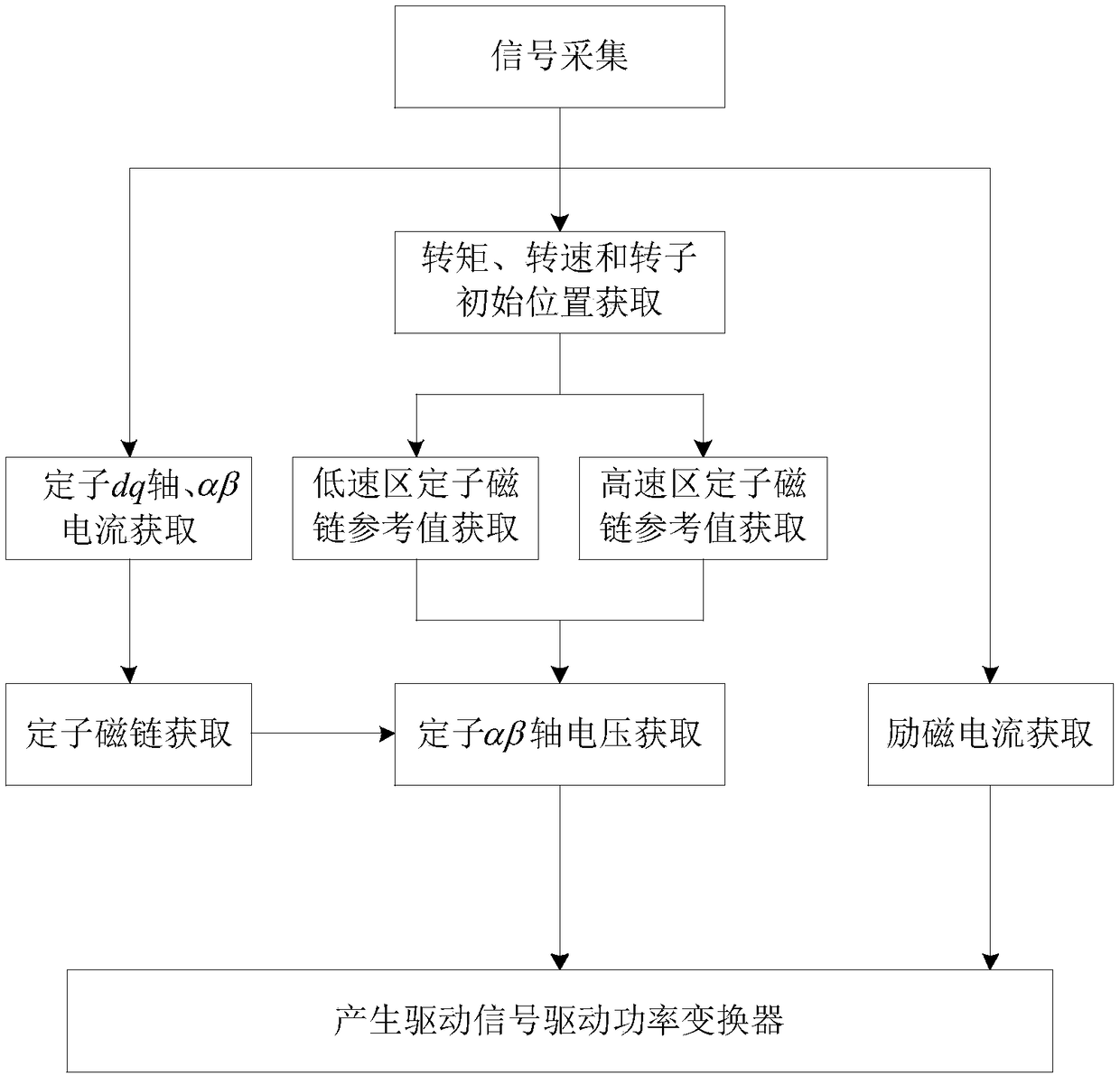

[0068] figure 1 It is a logic flow diagram of the method of the present invention, and the drive signal is obtained through signal acquisition and formula calculation to drive the power converter.

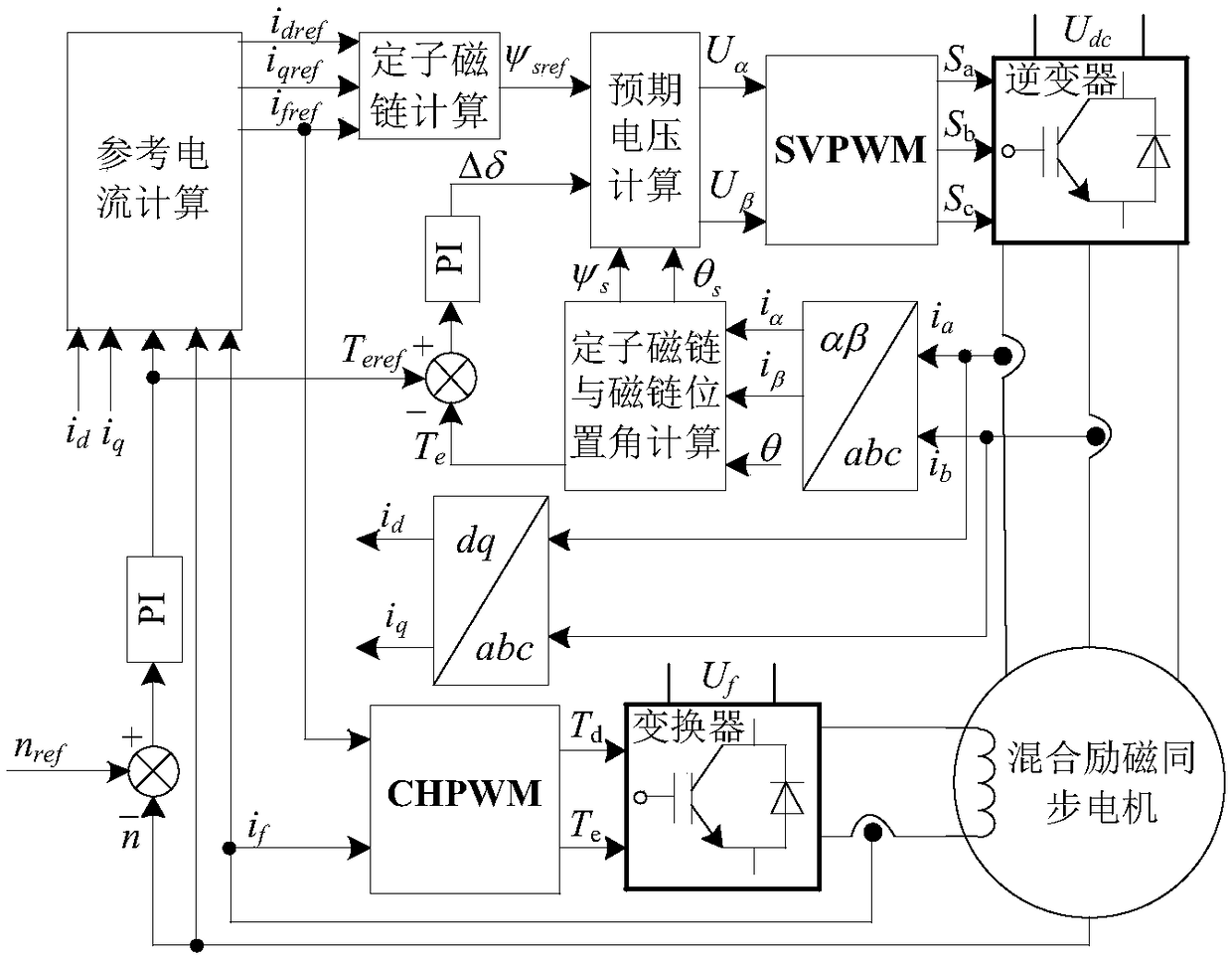

[0069] figure 2 In order to realize the control system block diagram of the present invention, the control system consists of a reference current calculation module, a voltage space vector pulse width modulation (SVPWM) module, an inverter, a hybrid excitation synchronous motor, a power converter, and a pulse width that eliminates specified order harmonics Modulation (SHEPWM) module and stator flux and flux position angle calculation module.

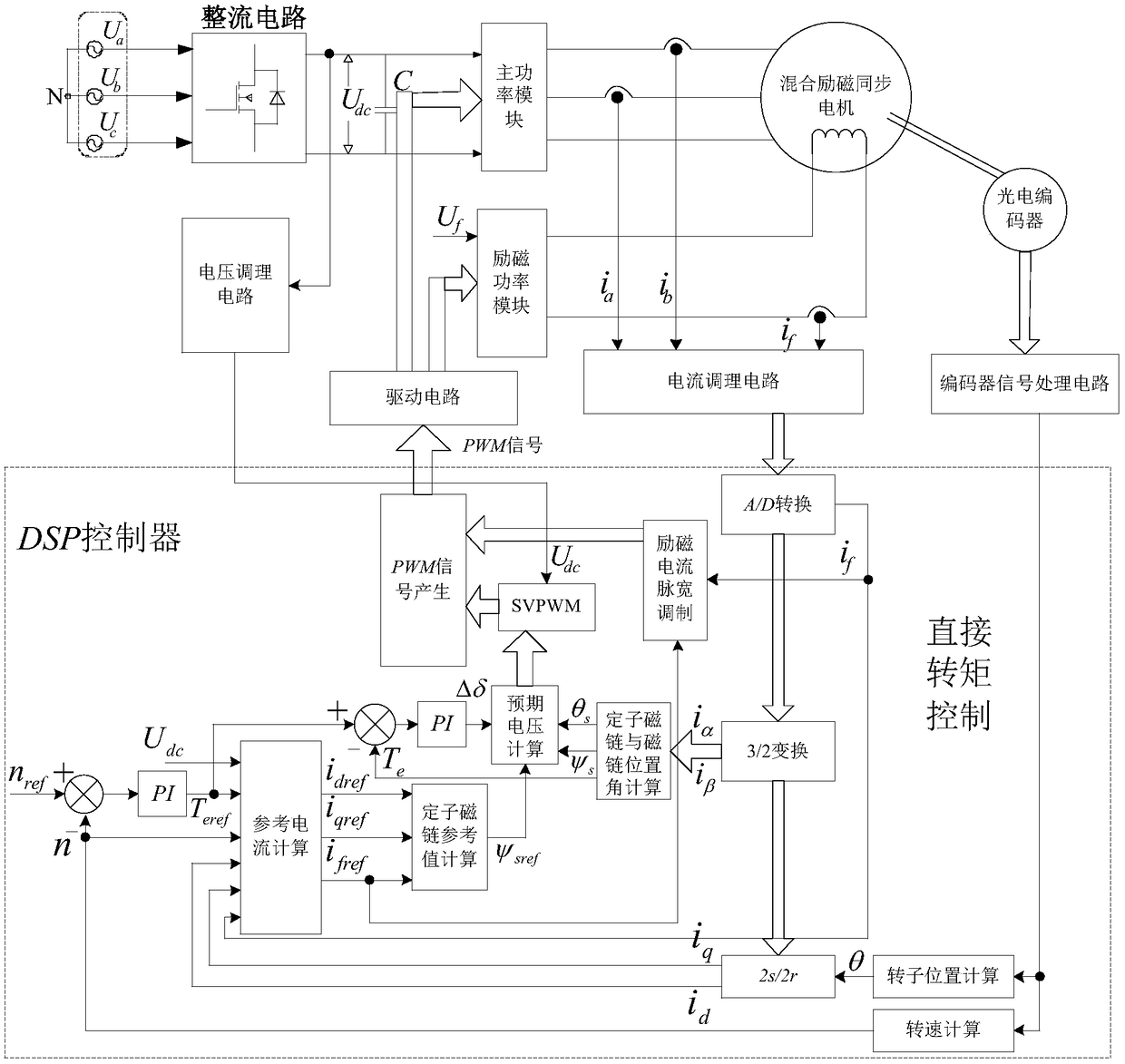

[0070] image 3 In order to realize the system structure block diagram of the method of the present invention, the system is composed of an AC power supply, a rectifier, a voltage stabilizing capacitor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com