Piezoelectric thin-film resonator, method for manufacturing the same, and method for detecting blood coagulation time

A technology of piezoelectric film and manufacturing method, which is applied in the field of clinical medical testing, can solve the problems of difficult manufacturing, large external noise, and large amount of blood samples, etc., and achieve the effects of accurate judgment of blood coagulation time, low output noise, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

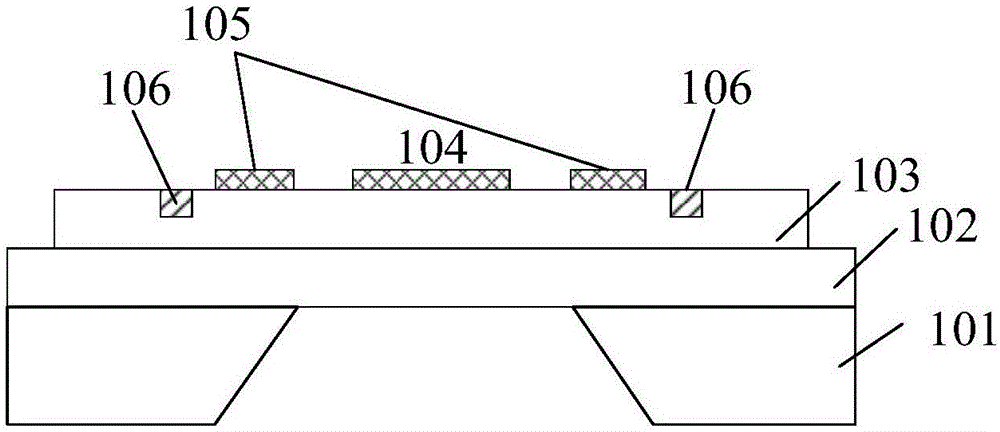

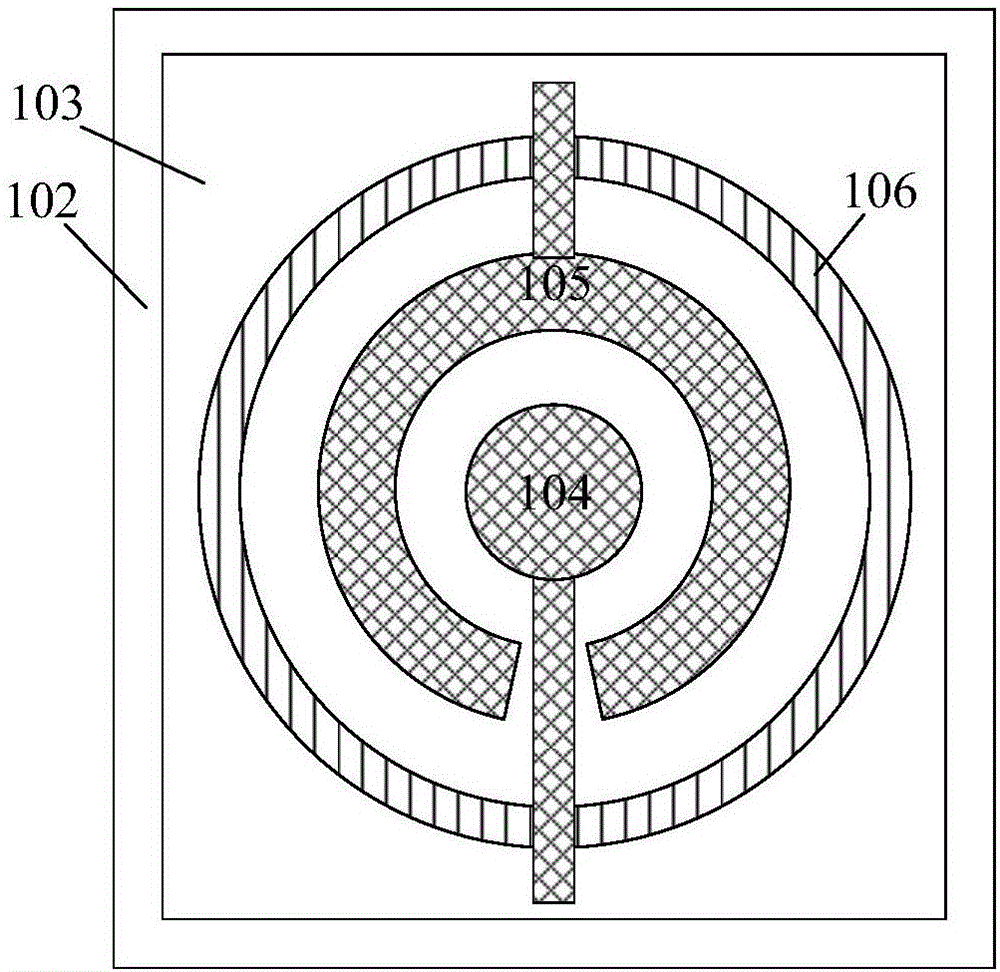

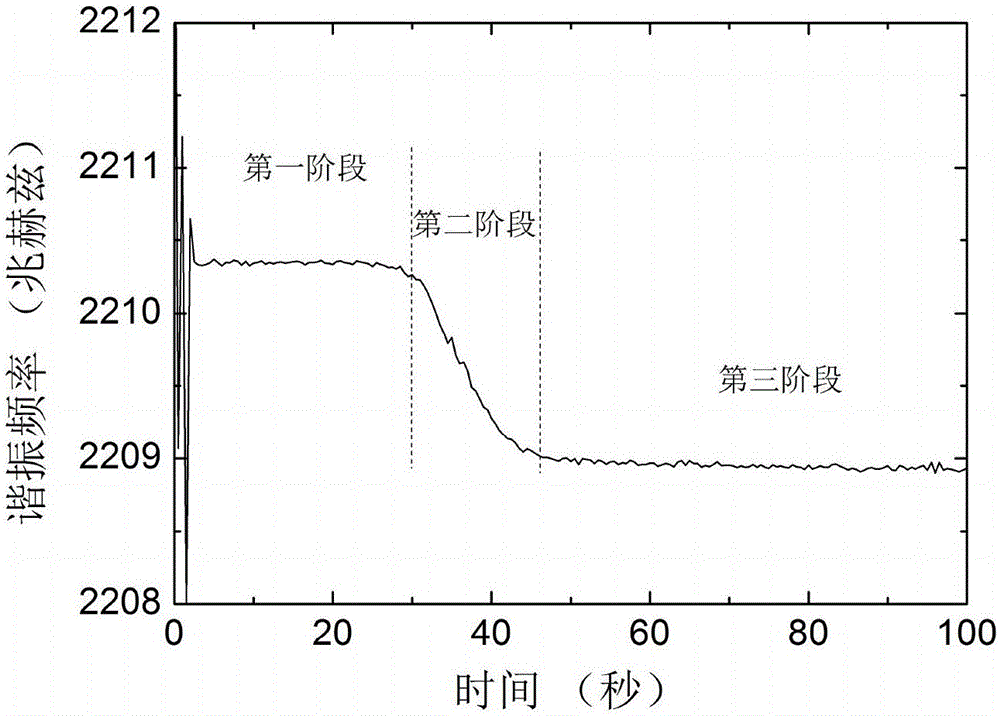

[0041] The piezoelectric thin film resonator used in the present invention is generally composed of a silicon substrate, a supporting film layer, a piezoelectric layer and electrodes, and its structure can be a diaphragm model, an air gap type, and a solid assembly type. In order to ensure that the thin film resonator can effectively resonate in the blood viscous environment, it is better to use a piezoelectric thin film resonator operating in the shear wave mode for the measurement of coagulation time. The electrodes of the piezoelectric thin film resonator can be arranged in parallel on the upper surface of the piezoelectric layer, or placed on both sides of the piezoelectric layer. The shape of the piezoelectric thin film resonator electrodes can be circular, square or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com