A super high-early-strength polycarboxylic acid water reducer and a preparing method thereof

A super early-strength, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problem of not having a good solution, and achieve the effects of high water reduction rate, low dosage, and smooth and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

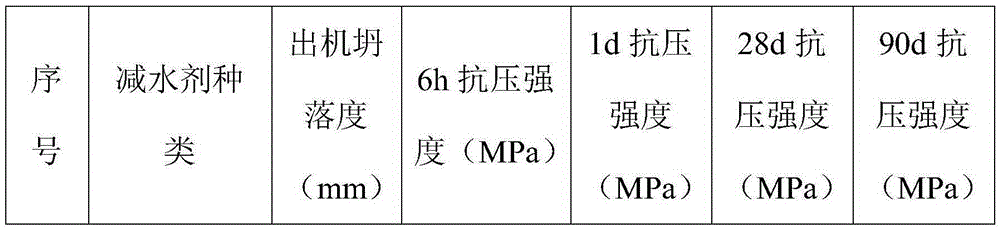

Examples

preparation example Construction

[0022] The invention discloses a super early strength polycarboxylate water reducer, the preparation method of which comprises the following steps:

[0023] (1) 25-35 parts of monomer C, 15-25 parts of monomer D, 1.5-2.5 parts of chain transfer agent, and 50-70 parts of deionized water are mixed and stirred evenly as small material A in the above parts by weight;

[0024] Wherein, monomer C is one or more of acrylic acid, methacrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, maleic anhydride, fumaric acid, aconitic acid;

[0025] Monomer D is one or more of acrylamide, N-isopropylacrylamide, N,N-dimethylacrylamide, and dimethylaminoethyl methacrylate;

[0026] The chain transfer agent is one or both of mercaptopropionic acid and mercaptoacetic acid.

[0027] (2) 0.6-0.9 parts of reducing agent and 100-120 parts of deionized water in the above parts by weight; mixed and stirred evenly as small material B;

[0028] The reducing agent is one or both of vitamin C and sodi...

Embodiment 1

[0035] Add 400 parts of accurately measured deionized water and 400 parts of methallyl polyoxyethylene-oxypropylene polyamine polyether into the four-necked bottle, and put the four-necked bottle into a constant temperature water bath with a temperature of 30°C. After stirring and dissolving, wait until the temperature is stabilized at 30°C, add 1.5 parts of hydrogen peroxide and stir evenly, and start adding small ingredients A and B dropwise after 5 minutes (small ingredient A consists of 20 parts of acrylic acid, 5 parts of methacrylic acid, and 15 parts of acrylamide , 1.5 parts of mercaptopropionic acid was added to 50 parts of deionized water and stirred evenly, small material B was made by adding 0.6 parts of vitamin C to 120 parts of deionized water and stirred evenly), small material A was added for 3 hours, and small material B was dripped Adding time is 4 hours, keep warm for 1 hour after dropping, add 12 parts of sodium hydroxide, adjust pH to 5.45, and prepare supe...

Embodiment 2

[0037] Add 350 parts of accurately measured deionized water and 350 parts of methallyl polyoxyethylene-oxypropylene polyamine polyether into the four-necked bottle, and put the four-necked bottle into a constant temperature water bath with a temperature of 35°C. After stirring and dissolving, when the temperature is stabilized at 35°C, add 1.5 parts of hydrogen peroxide and 0.5 parts of ammonium persulfate and stir evenly. After 5 minutes, add small ingredients A and B dropwise (small ingredient A consists of 15 parts of acrylic acid, 3 parts of methacrylic acid 10 parts of 2-acrylamide-2-methylpropanesulfonic acid, 10 parts of acrylamide, 10 parts of dimethylaminoethyl methacrylate, 1.5 parts of mercaptopropionic acid and 60 parts of deionized water and stir evenly. Material B is made by adding 0.6 parts of vitamin C to 120 parts of deionized water and stirring evenly), the time for adding small material A is 3 hours, and the time for adding small material B is 4 hours. 10 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com