optical film

A technology of optical film and film thickness, which is applied in the field of optical film, can solve the problems of easy generation of chips, easy condensation, cracks, insufficient generation of chips, etc., and achieve the effects of increased strength, reduced cracks, and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0342] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these Examples. In addition, in an Example, the expression of "part" or "%" is used, and unless otherwise specified, it means "part by mass" or "% by mass".

[0343]

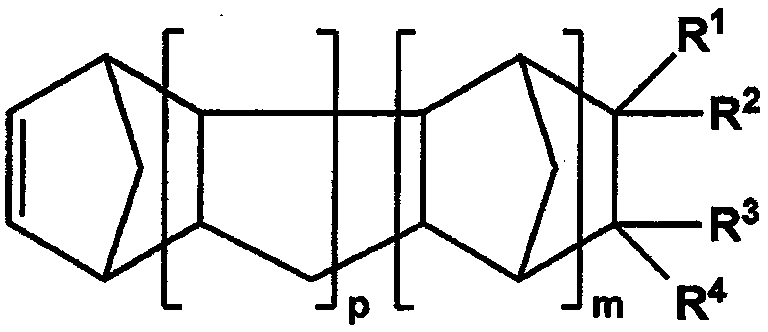

[0344] (Synthesis of Cycloolefin Resin P)

[0345] 8-methyl-8-methoxycarbonyltetracyclo[4.4.0.12,5.17,10]-3-dodecene (DNM) 75% by mass, dicyclopentadiene (DCP) 24% by mass, 2- 1% by mass of norbornene, 9 parts of 1-hexene as a molecular weight regulator, and 200 parts of toluene were put into a reaction vessel replaced with nitrogen, and heated to 110°C. 0.005 part of triethylaluminum and 0.005 part of methanol-modified WCl6 (anhydrous methanol:PhPOCl2:WCl6=103:630:427 mass ratio) were added thereto and reacted for 1 hour to obtain a polymer. The obtained polymer solution was placed in an autoclave, and 200 parts of toluene was added thereto. Next, add 0.006 parts of RuHCl(CO)[P(C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com