Magnetic magnesia adsorbent, preparation method therefor and application of magnetic magnesia adsorbent

A magnesium oxide and magnetic technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of limited magnetic materials for polycyclic aromatic hydrocarbons, and achieve magnetic separation and removal High efficiency and short adsorption equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Magnetic Fe 3 o 4 / MgO microspheres are prepared according to the following steps: (1) prepare Fe 3 o 4 Nanoparticles: Formulation of FeCl in Ethylene Glycol Solution 3 Mix the solution with sodium acetate, stir it magnetically for 8 hours, transfer the solution to an autoclave, react at 200°C for 10 hours, and after natural cooling, fully wash with absolute ethanol to obtain Fe with a particle size of 100-200nm 3 o 4 Particles, ready for use after vacuum drying; (2) Magnetic Fe 3 o 4 / MgO microspheres preparation: a, the preparation mass fraction is 5%~6% K 2 CO 3 Aqueous solution, adding 0.14% to 0.16% of sodium polyphosphate with a mass fraction of 16% to 18% of Mg(NO 3 ) 2 aqueous solution, transferred to a flask. Heat the solutions configured in a and b above to 70°C respectively, and weigh a certain amount of Fe prepared in step (1). 3 o 4 Nanoparticles were added to 30 μL secondary deionized water, ultrasonically dispersed for 15 min, and K 2 CO 3 T...

Embodiment 2

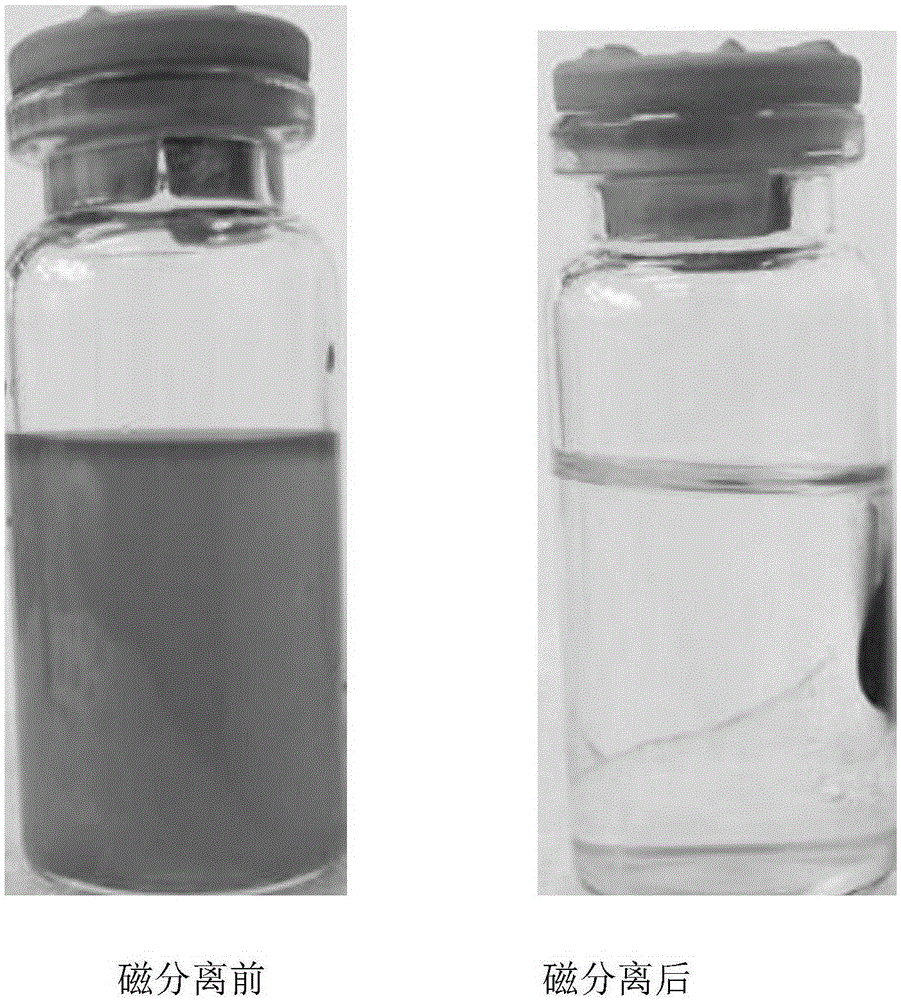

[0029] Weigh the prepared magnetic magnesium oxide microspheres and add them to the mixed water sample of polycyclic aromatic hydrocarbons, disperse the magnetic particles by ultrasonication for 1-5 minutes, and perform vibration adsorption on the obtained suspension. After the adsorption is completed, use an external magnetic field to separate the magnetic material and water sample separation (eg figure 1 ). The content of polycyclic aromatic hydrocarbons in the mixed water sample is 0.01-5 mg / L.

[0030] In the oscillation adsorption, the amount of magnetic material added is 0.01-4 g / L.

[0031] The oscillating adsorption temperature is 20-40°C, preferably 25°C; the pH value of the mixed water sample during the oscillating adsorption process is 4.0-8.0, and the sodium chloride content is 0-20g / L.

[0032] The vibration frequency of the vibration adsorption is 140-180 rpm, preferably 150 rpm; the vibration time is 5-300 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com