Basalt fiber reinforced modified polyolefin double-wall hollow twined drainage pipe

A basalt fiber and polyolefin technology is applied in the field of basalt fiber reinforced modified polyolefin double flat-wall hollow winding drainage pipes, which can solve problems such as cost increase, stiffness, strength, thermal distortion temperature reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

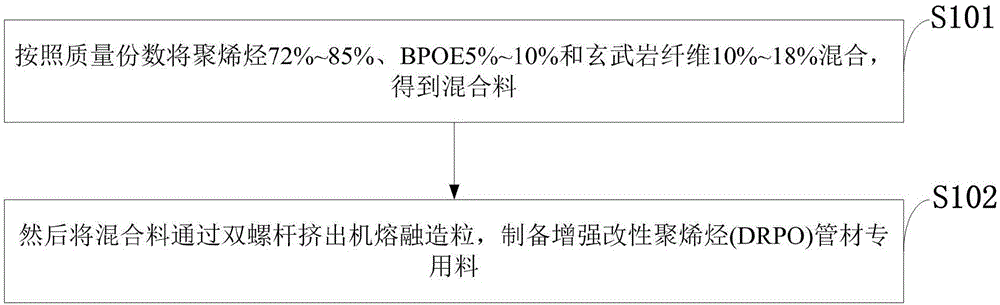

[0028] Such as figure 1 As shown, the preparation method of the basalt fiber-reinforced modified polyolefin double-flat-wall hollow wound drainage pipe provided in the embodiment of the present invention includes the following steps:

[0029] S101: Mix 72% to 85% of polyolefin, 5% to 10% of BPOE and 10% to 18% of basalt fiber according to the parts by mass to obtain a mixture;

[0030] S102: Then melt and granulate the mixed material through a twin-screw extruder to prepare a special material for reinforced modified polyolefin (DRPO) pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com