Environment-friendly VPI impregnated resin for wind driven generator and preparation method thereof

A wind turbine and resin-impregnated technology, applied in epoxy resin coatings, circuits, electrical components, etc., can solve the problems of large curing volatile content, low bonding strength, large dielectric loss, etc., and achieve low viscosity and high adhesion. The effect of strength, low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

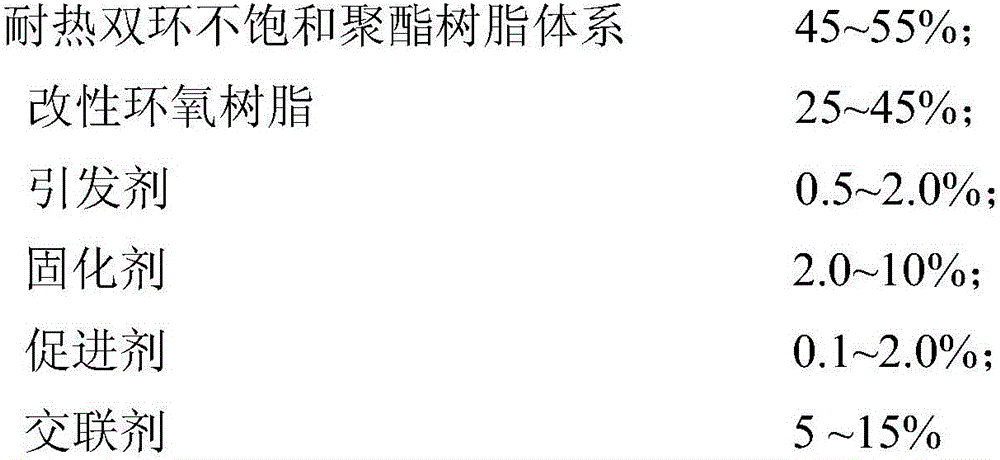

[0037] In the present embodiment, the formula of environment-friendly type wind power generator VPI impregnated resin is as follows:

[0038] The heat-resistant bicyclic unsaturated polyester is composed of a molar ratio of dicyclopentadiene:maleic anhydride:neopentyl glycol:terephthalic acid:fumaric acid:methylpropanediol=0.6:0.5:2.3:1.0:1.0: Various monomers of 0.6 are prepared by polycondensation reaction.

[0039] The heat-resistant bicyclic unsaturated polyester system is obtained by mixing the heat-resistant bicyclic unsaturated polyester prepared above with trimethylolpropane diallyl ester (TMPTA) at a mass ratio of 6:4.

[0040] The modified epoxy resin is obtained by adding unsaturated polyester and epoxy resin (bisphenol A type epoxy resin) in a mass ratio of 10:100 and then adding them.

[0041] The unsaturated polyester is composed of various monomers with a molar ratio of phthalic anhydride: neopentyl glycol: diethylene glycol: benzoic acid: dimethylol propionic ...

Embodiment 2

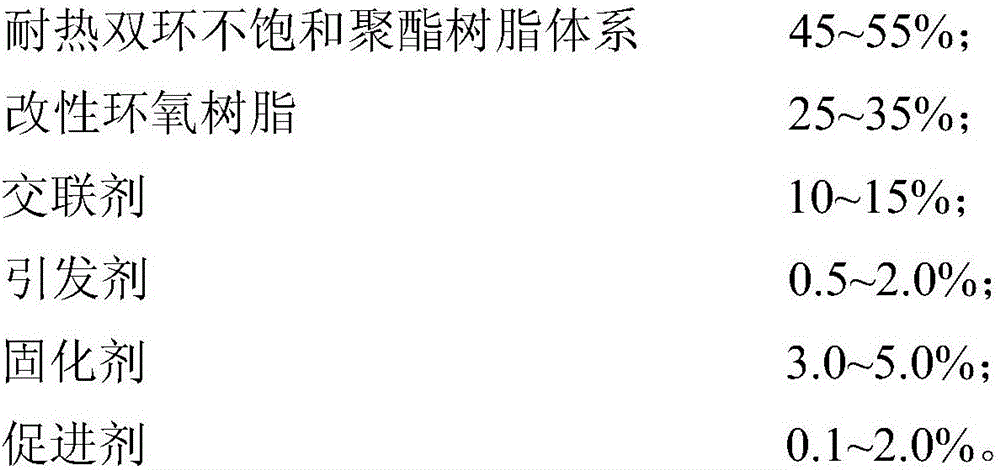

[0046] The formula of the environment-friendly wind power generator of this example VPI impregnated resin is:

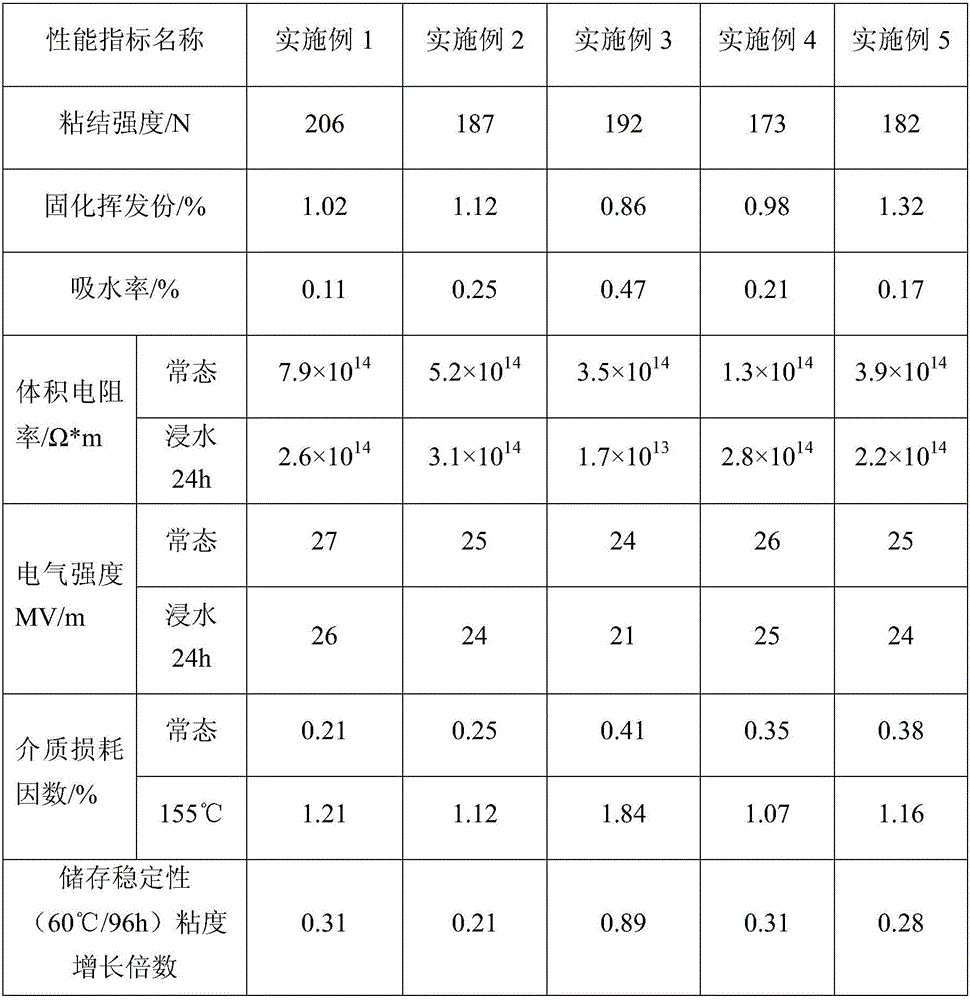

[0047] 50 grams of heat-resistant bicyclic unsaturated polyester, 30 grams of modified epoxy resin, 1.4 grams of benzoyl peroxide (BPO) as the initiator, 10 grams of phthalic acid diacrylate (DAP) as the crosslinking agent, and 10 grams of curing agent It is 5 grams of tung oil anhydride and 0.6 g of accelerator aluminum acetylacetonate.

[0048] After the above-mentioned components are uniformly mixed according to the formula, and then mixed with other components uniformly according to the formula, the environment-friendly VPI impregnated resin for wind power generators is obtained. When the impregnating resin is used, it should firstly be cured at 140-150°C for 4-6 hours, and then be cured at 170-180°C for 8-10 hours to form a film.

Embodiment 3

[0050] The formula of the environment-friendly wind power generator of this example VPI impregnated resin is:

[0051] 50 grams of heat-resistant bicyclic unsaturated polyester, 30 grams of modified epoxy resin, 1.6 grams of benzoyl peroxide (BPO) as the initiator, 10 grams of dodecyl allyl ester as the crosslinking agent, and 10 grams of phthalate 5 grams of formic acid diacrylate (DAP), 3 grams of phenylimidazole as a curing agent, and 0.6 g of an accelerator aluminum acetylacetonate.

[0052] After the above-mentioned components are uniformly mixed according to the formula, and then mixed with other components uniformly according to the formula, the environment-friendly VPI impregnated resin for wind power generators is obtained. When the impregnating resin is used, it should firstly be cured at 140-150°C for 4-6 hours, and then be cured at 170-180°C for 8-10 hours to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com