High-weatherable single-component organosilicon concrete protective coating and preparation method thereof

A protective coating, silicone technology, applied in the direction of coating, can solve the problems of poor cracking resistance and construction performance, the coating is prone to bulge, poor air permeability, etc., and achieves strong environmental adaptability, alkali resistance and UV resistance. Excellent aging performance and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

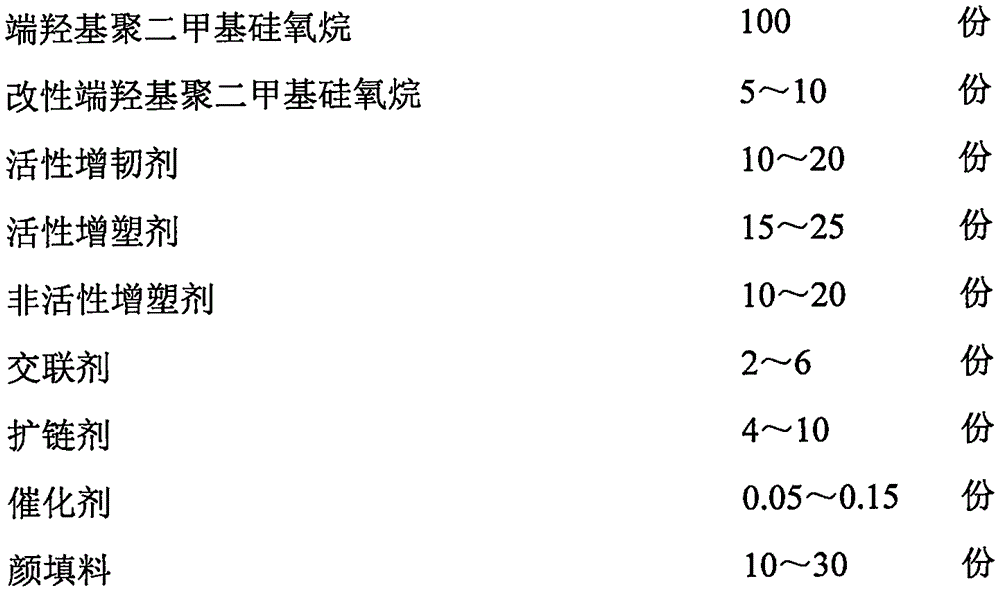

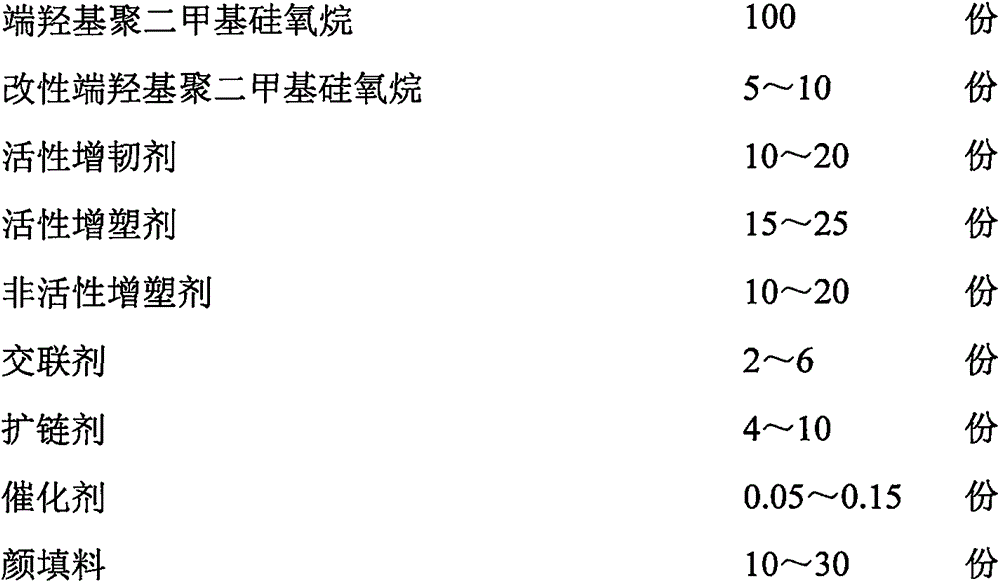

Method used

Image

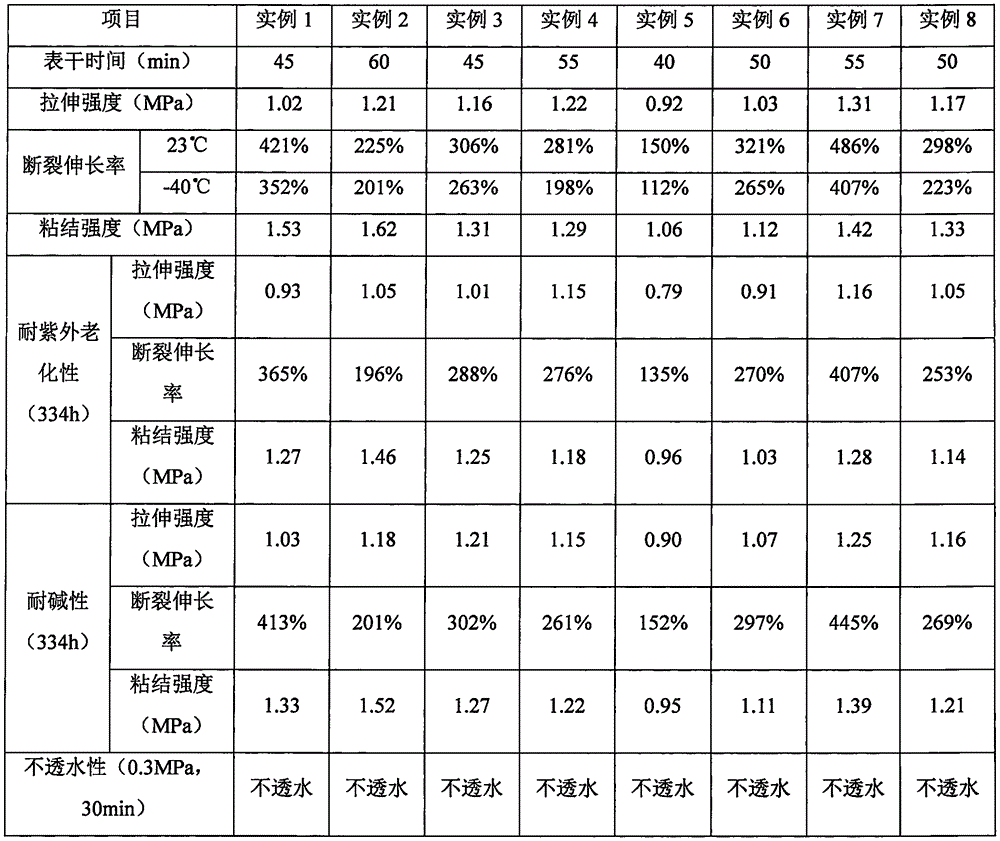

Examples

Embodiment 1

[0040]100 parts of hydroxyl-terminated polydimethylsiloxane, 2 parts of diphenylsiloxane-modified hydroxyl-terminated polydimethylsiloxane, 3 parts of tolylsiloxane-modified hydroxyl-terminated polydimethylsiloxane Parts, 5 parts of silicone diol, 5 parts of silicone polyether diol, 10 parts of low-viscosity terminal hydroxyl polymethylsilane, 5 parts of MDT type silicone oil, 3 parts of dimethyl silicone oil and 7 parts of paraffin mixture In the reaction kettle, vacuum dehydrate at 110°C for 2h; 2 parts of pigment, 1 part of carbon black, 0.5 parts of fumed silica, 4.5 parts of superfine calcium carbonate and 2 parts of diatomaceous earth are dried in a drying oven at 110°C for 2 hours ; Add the dried pigments and fillers to the reaction kettle and stir for 20 minutes; Put the rubber material into the three-roll mill for grinding, the grinding fineness is 20 μm, and cool the rubber material to room temperature; Put the ground rubber material into the planetary stirring tank ...

Embodiment 2

[0042] 100 parts of hydroxyl-terminated polydimethylsiloxane, 6 parts of diphenylsiloxane-modified hydroxyl-terminated polydimethylsiloxane, 4 parts of tolylsiloxane-modified hydroxyl-terminated polydimethylsiloxane 11 parts of silicone diol, 9 parts of silicone polyether diol, 20 parts of low-viscosity terminal hydroxyl polymethylsilane, 5 parts of MDT type silicone oil, 8 parts of dimethyl silicone oil and 12 parts of paraffin mixture Vacuum dehydration at 130°C for 2 hours in a reaction kettle; 1 part of pigment, 2 parts of carbon black, 0.3 parts of fumed white carbon black, 13 parts of superfine calcium carbonate and 13.7 parts of diatomite were dried in a drying oven at 130°C for 2 hours ; Add the dried pigments and fillers to the reaction kettle and stir for 40 minutes; Put the rubber material into the three-roll mill for grinding, the grinding fineness is 40 μm, and cool the rubber material to room temperature; Put the ground rubber material into the planetary stirring ...

Embodiment 3

[0044] 100 parts of hydroxyl-terminated polydimethylsiloxane, 7.5 parts of diphenylsiloxane-modified hydroxyl-terminated polydimethylsiloxane, 15 parts of silicone diol, 20 parts of low-viscosity hydroxyl-terminated polymethylsiloxane 15 parts and 15 parts of dimethyl silicone oil were added to the reaction kettle, and vacuum dehydrated at 120 ° C for 2 hours; 2 parts of pigments, 0.1 parts of fumed silica and 17.9 parts of ultrafine calcium carbonate were dried in a drying oven at 120 ° C for 2 hours; Add the dried pigments and fillers to the reaction kettle and stir for 30 minutes; put the rubber material into a three-roller grinder for grinding, the grinding fineness is 30 μm, and cool the rubber material to room temperature; put the ground rubber material into a planetary stirring tank, and Stir under vacuum for 30 minutes; add 2 parts of ketoximosilane crosslinking agent, 2 parts of allyloxysilane crosslinking agent and 7 parts of amidosilane chain extender, and stir under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com